KunjaniCNC Machininguya muva nje?

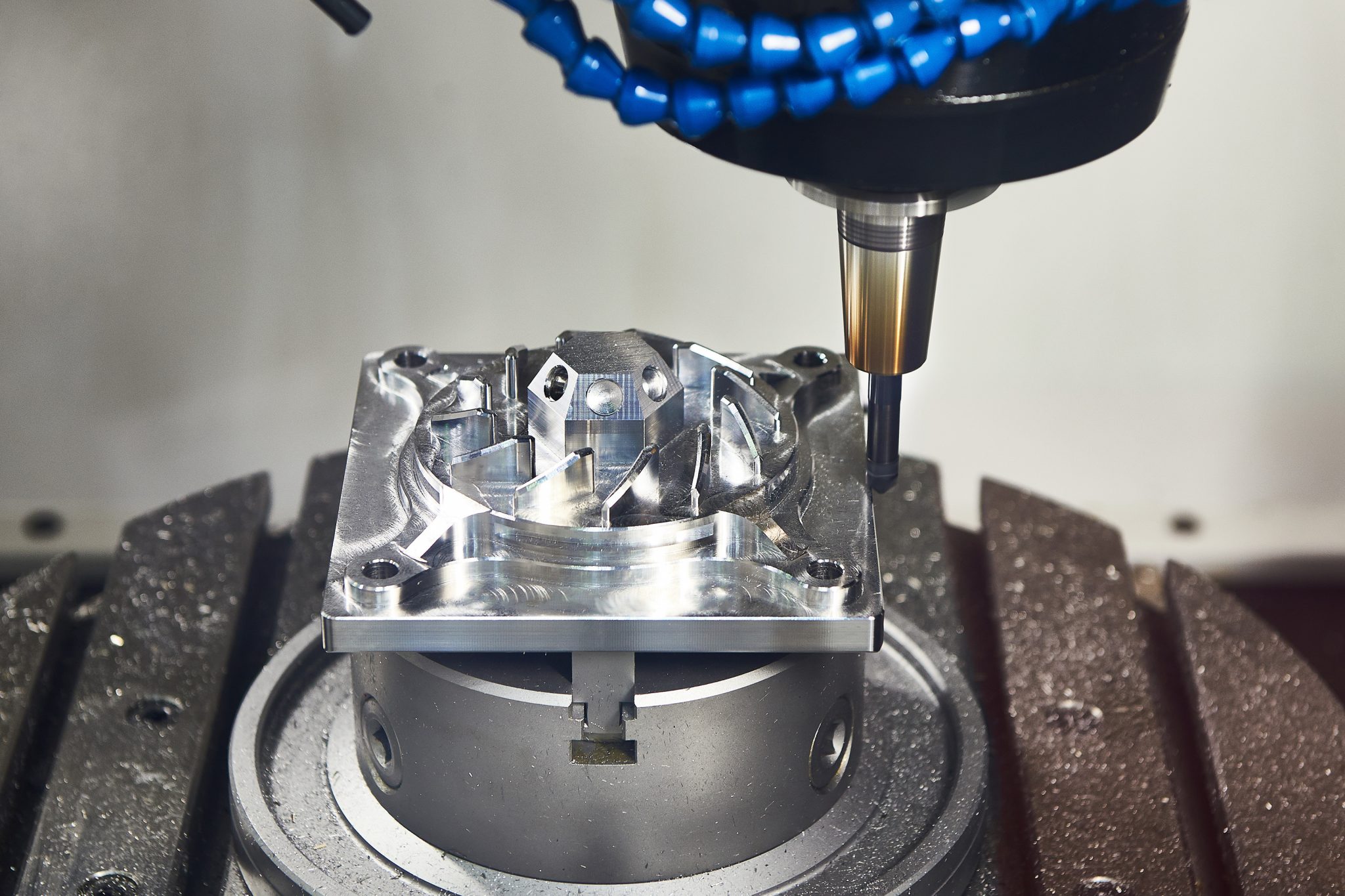

Njengamanje, ekucutshungulweni kwezingxenye zemishini ezinembile, izinto zamathuluzi ezifanele ukucubungula insimbi engagqwali ziyinsimbi enesivinini esikhulu kanye ne-carbide enosimende.Izisiki zokugaya zensimbi ezinesivinini esikhulu zilula ukwenza, azibizi, zibukhali, futhi ziqinile, kodwa azikwazi ukugqokwa kahle.Inqubo yokukhiqiza yabasiki be-carbide abagaywe ngosimende iyinkimbinkimbi futhi iyabiza, futhi inokumelana okuhle nokugqokwa ngaphansi kwezimo zokusika ngesivinini esikhulu, okusiza ekuzinzeni kokunemba kobukhulu bokunemba kokucubungula izingxenye zemishini.

Ukucabangela ngokugcwele izici ze-CNC machining kanye nomnotho wokukhiqiza, lezi zimiso ezilandelayo zingamukelwa: sebenzisa ama-cutters okugaya insimbi asebenza ngesivinini esiphezulu ukuze aqedele, ngoba ama-blades of high-speed high-speed steel milling cutters abukhali ngokuqhathaniswa.Imishini enzima idinga ukunemba okuphansi kwesilungiselelo samathuluzi, ukulungiselelwa kwamathuluzi okulula, isikhathi esifushane sokusiza, nezindleko zokukhiqiza eziphansi.Lapho uqeda, sebenzisa izigayo zokugcina ze-carbide ezinembayo eziphezulu, ezingasika ngesivinini esikhulu futhi zigcine ukunemba kwemishini eqhubekayo nokuzinzileukunemba izingxenye zemishini.Ngaphansi kwezimo ezijwayelekile, ukuqedwa kwemikhiqizo eminingi noma amakhulu kungaqedwa.

Ukukhethwa kwamapharamitha ejiyomethri yethuluzi: Ukukhetha ithuluzi ohlwini lwamagama olukhona ngokuyinhloko kudinga ukucabangela amapharamitha ejometri njengenani lamazinyo, i-rake angle kanye ne-blade helix angle.Enqubweni yokuqeda, ama-chips ensimbi engagqwali akulula ukugoqa.Ithuluzi elinamazinyo ambalwa kanye nephakethe le-chip elikhulu kufanele likhethwe ukwenza ukukhishwa kwe-chip kushelele futhi kunenzuzo ekucutshungulweni kwezingxenye zemishini ezinembayo zensimbi engagqwali.

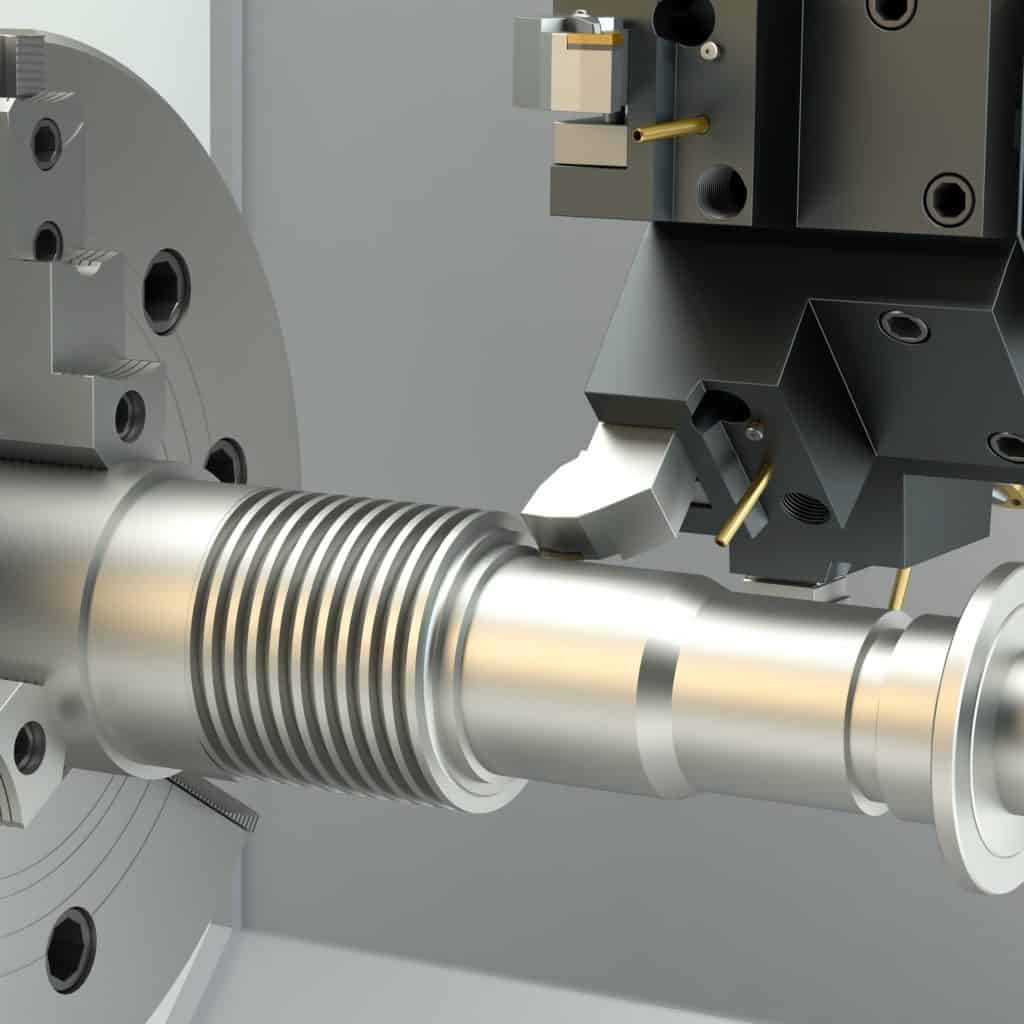

Kodwa-ke, uma i-engeli ye-rake inkulu kakhulu, izowenza buthaka amandla nokumelana nokugqoka konqenqema lokusika lwethuluzi.Ngokuvamile, umshini wokugcina one-rake angle evamile yama-degree angu-10-20 kufanele kukhethwe.I-engeli ye-helix ihlobene eduze ne-rake angle yangempela yethuluzi.Lapho ucubungula insimbi engagqwali, ukusetshenziswa kwe-helix angle milling cutter enkulu kungenza amandla okusika abe mancane endaweni.ukunemba imishiniinqubo futhi machining uzinzile.

Izinga eliphezulu le-workpiece liphezulu, futhi i-engeli ye-helix ngokuvamile ingu-35°-45°.Ngenxa yokusebenza kabi kokusika, izinga lokushisa eliphezulu lokusika kanye nempilo yethuluzi elifushane lezinto zensimbi engagqwali.Ngakho-ke, ukusetshenziswa kokusika kwensimbi engagqwali yokugaya kufanele kube ngaphansi kwalokho kwensimbi ye-carbon evamile.

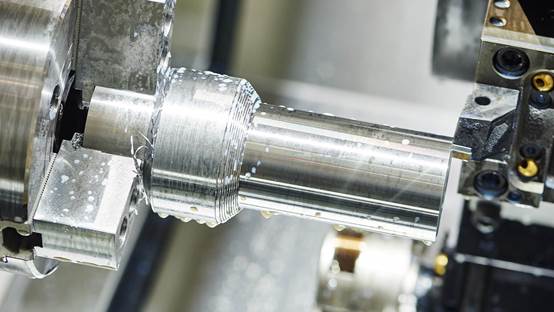

Ukupholisa okwanele nokugcobisa kunganweba kakhulu impilo yamathuluzi futhi kuthuthukise ikhwalithi yangaphezulu yezingxenye zemishini ezinembayo ngemva kokucubungula.Ekukhiqizeni kwangempela, uwoyela okhethekile wokusika insimbi engagqwali angakhethwa njenge-coolant, futhi umsebenzi wokuphuma kwamanzi wesikhungo sokucindezela okuphezulu kwe-spindle yamathuluzi womshini ungakhethwa.Amafutha okusika afafazwa endaweni yokusika ngokucindezela okukhulu ukuze kuphole ngempoqo kanye nokugcoba ukuze kutholwe umphumela omuhle wokupholisa nokugcoba.

As izinkampani zokukhiqiza imishiniqhubeka nokuthuthukisa ukunemba kwezingxenye nezingxenye, umshini we-CNC udlala indima ebaluleke kakhulu kuyo yonke inqubo yokukhiqiza, futhi amathuluzi omshini we-CNC amaningi athengwa, okuholela ochungechungeni lwezinkinga ezidinga ukuxazululwa ngokuphuthumayo..Enqubweni yokucubungula izingxenye zemishini ngokunemba, amathuluzi okusika, njengethuluzi elibalulekile elisizayo lokubamba iqhaza emisebenzini yokukhiqiza, adlala indima enkulu ekukhiqizeni amathuluzi omshini we-CNC kanye nokunemba nokunemba kokunemba kwezingxenye zokucubungula nokukhiqiza, ikakhulukazi ekwandeni okukhulayo. inombolo yamathuluzi omshini we-CNC.Ukuze kuxazululwe ububi obulethwa abaphathi abahlukaniselwe izindawo, kuthuthukiswe ukusebenza kahle kokucubungula izingxenye zemishini, kanye nokunciphisa izindleko zokusebenza, inani lamathuluzi likhulu.Khona-ke, amathuluzi kufanele aphathwe ngendlela eyodwa.

Isikhathi sokuthumela: Mar-15-2021