Ukuzenzakalela Kwemishini

Kubandakanya ama-alloys athambile azibuthe asuselwa ku-nickel, ama-alloys okumelana nokunemba asuselwa ku-nickel nama-alloys e-electrothermal asuselwa ku-nickel. Ama-alloys athambile azibuthe asetshenziswa kakhulu ama-permalloy aqukethe cishe u-80% wenikeli. Zinezinga eliphezulu eliphezulu lokungena nokungena kokuqala kanye nokuphoqelela okuphansi. Ziyizinto ezibalulekile ezibalulekile embonini ye-elekthronikhi. Izakhi eziyinhloko ze-alloying ye-nickel-based precision resistance alloys yi-chromium, i-aluminium, nethusi.

Le alloy ine-resistivity ephezulu, i-coefficient yokushisa ephansi ye-resistivity kanye nokumelana nokugqwala okuhle, futhi isetshenziselwa ukwenza izinto eziphikisayo. Ingxubevange ye-electrothermal esekelwe ku-nickel iyingxubevange ye-nickel equkethe u-20% we-chromium, enezindawo ezinhle zokuqeda i-oxidation kanye ne-anti-corrosion, futhi ingasetshenziswa isikhathi eside ekushiseni kuka-1000-1100 °C.

I-Memory Alloy

Ingxubevange ye-nickel ene-50(at)% titanium. Izinga lokushisa lokubuyisela lingu-70°C, futhi umphumela wenkumbulo yomumo muhle. Ushintsho oluncane lwesilinganiso sokwakheka kwe-nickel-titanium lungashintsha izinga lokushisa lokubuyisela ngaphakathi kwebanga elingu-30 ukuya ku-100 °C. Isetshenziswa kakhulu ekwenzeni izingxenye zesakhiwo ezizikhulisayo ezisetshenziswa kumkhumbi-mkhathi, izinsimbi eziziqinisayo ezisetshenziswa embonini ye-aerospace, amamotho enhliziyo yokwenziwa asetshenziswa ku-biomedicine, njll.

Inkambu yohlelo lokusebenza

Ama-alloys asekelwe ku-nickel asetshenziswa emikhakheni eminingi, njenge:

1. Ulwandle: izakhiwo zasolwandle endaweni yasolwandle, ukukhipha usawoti emanzini olwandle, i-aquaculture yamanzi olwandle, ukushintshanisa ukushisa kwamanzi olwandle, njll.

2. Inkambu yokuvikela imvelo: idivayisi ye-flue gas desulfurization yokukhiqiza amandla ashisayo, ukuhlanzwa kwamanzi angcolile, njll.

3. Inkundla yamandla: ukukhiqizwa kwamandla e-athomu, ukusetshenziswa okuphelele kwamalahle, ukukhiqizwa kwamandla olwandle, njll.

4. Inkambu ye-Petrochemical: ukucwenga uwoyela, imishini yamakhemikhali namakhemikhali, njll.

5. Inkundla yokudla: ukwenza usawoti, ukuphiswa kwesoso yesosi, njll. Ezindaweni eziningi ezingenhla, insimbi engagqwali evamile engu-304 ayisebenzi. Kule mikhakha ekhethekile, insimbi ekhethekile engenasici ibalulekile futhi ayinakushintshwa. Eminyakeni yamuva nje, ngokuthuthuka okusheshayo komnotho kanye nokuthuthuka okuqhubekayo kwezinga lomkhakha wezimboni, imiklamo eminingi idinga insimbi engagqwali yezinga eliphezulu. Ngokukhula kwesidingo sama-alloys asuselwa ku-nickel ezimbonini ezahlukahlukene. Ngo-2011, izinga lemakethe ye-nickel esekelwe ku-nickel yezwe lami lafinyelela kuma-yuan ayizigidi eziyizinkulungwane ezingu-23.07, izinga lokukhula lonyaka lika-19.47%. Ngakho-ke, izinga lokuthuthuka kwemboni lilokhu likhuphuka njalo.

Ukuthuthukiswa ngempumelelo kwemishini emikhulu ehlukahlukene kwenze ukwakhiwa kwamaphrojekthi abalulekile ahlukahlukene kwenzeka; ukunemba kwemishini nemishini kuye kwaqhuba imboni ye-microelectronics kanye nemboni yamakhompyutha. Ukukhiqizwa okudidiyelwe kakhulu kwamasekethe ahlanganisiwe kuye kwabonakala futhi amandla enkumbulo aphindwe kabili; ukuthuthukiswa nokukhiqizwa kwendawo yezindiza kanye nezikhali nemishini ehlukahlukene, ukuthuthukiswa kwesayensi nobuchwepheshe kanye nemfundo konke kuncike ekuthuthukisweni kokuklama kwemishini kanye nobuchwepheshe bokukhiqiza.

Lokhu okukhulu kuhlakulela ulwazi oluyisisekelo kanye nekhono lokusebenzisa lokuklama kwemishini nokukhiqiza, kanye nokuthuthukiswa kwemikhiqizo emisha ye-electromechanical.

Thumela umlayezo wakho kithi:

-

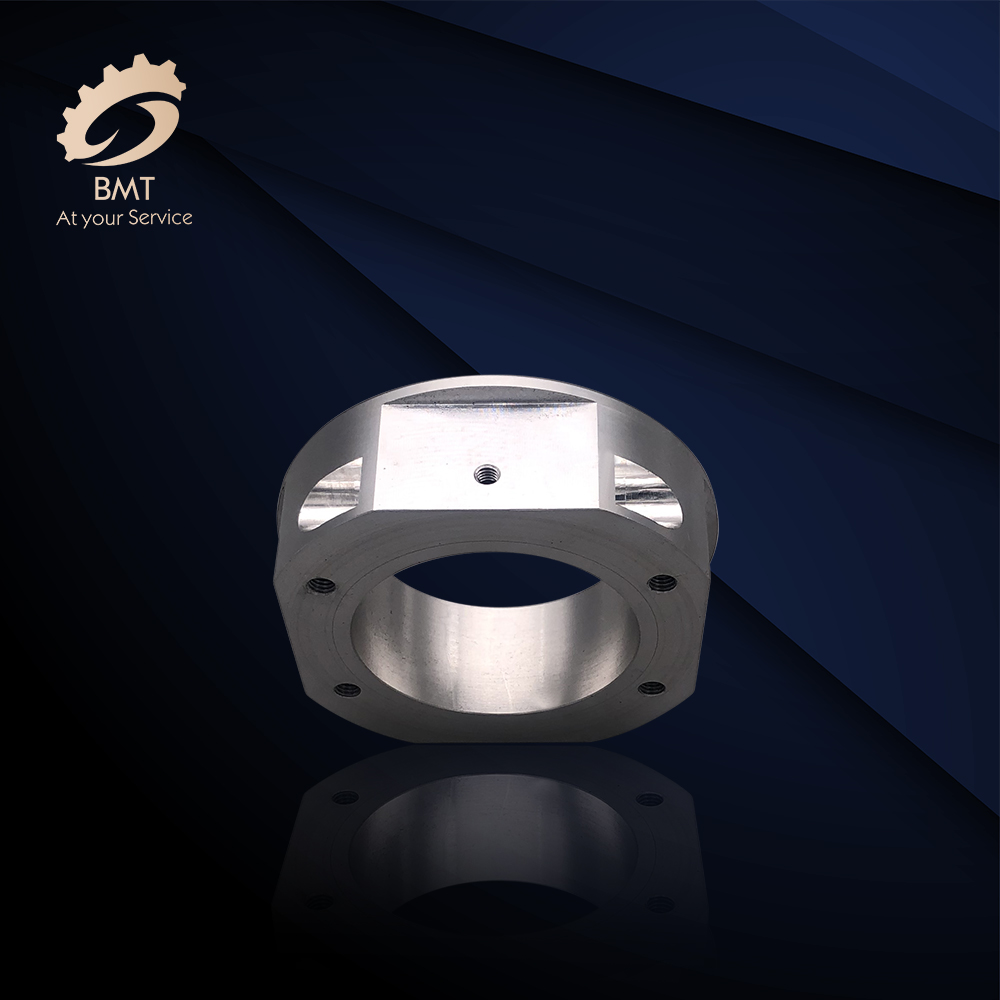

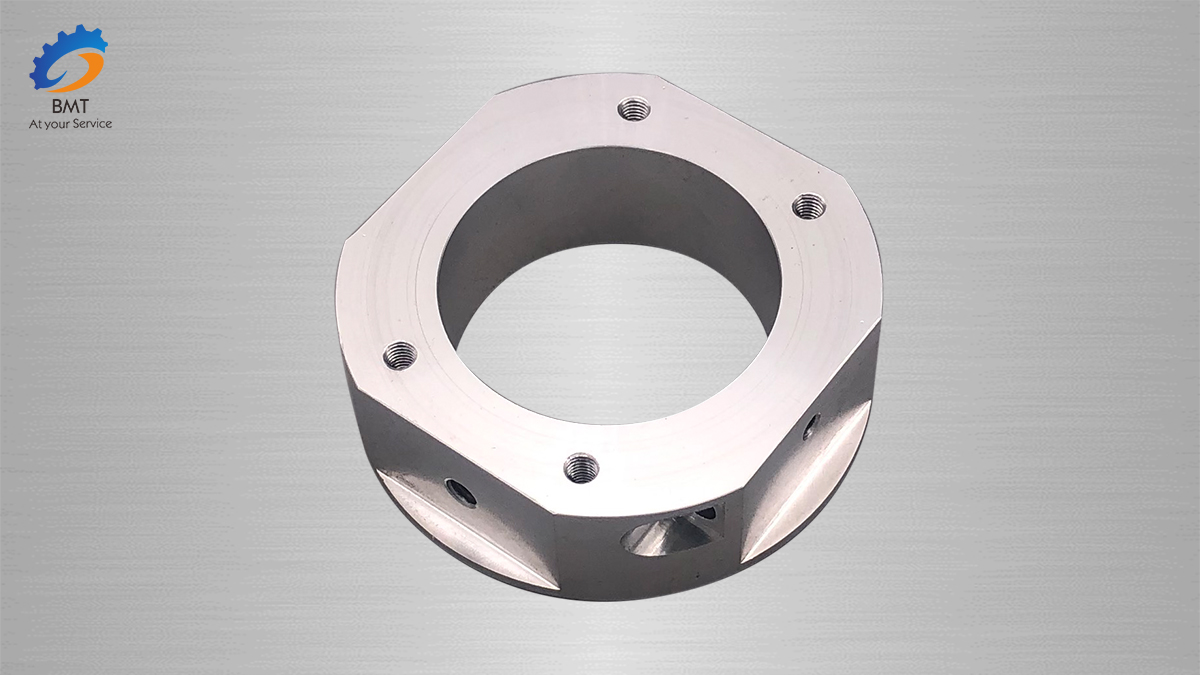

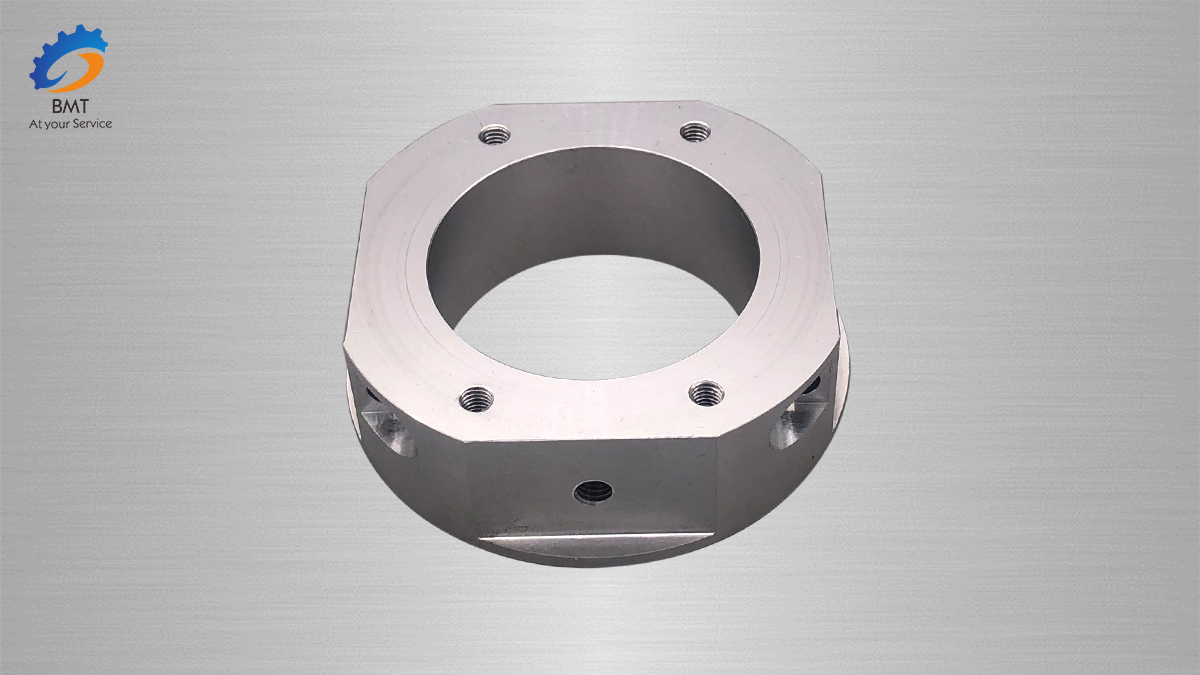

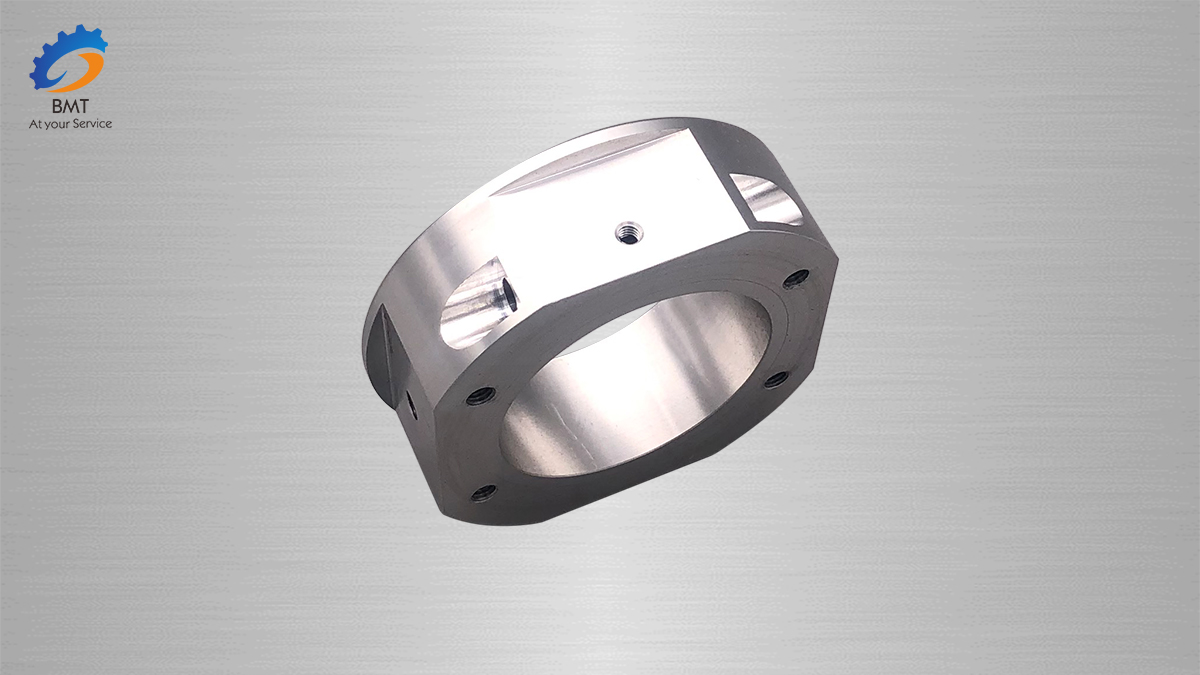

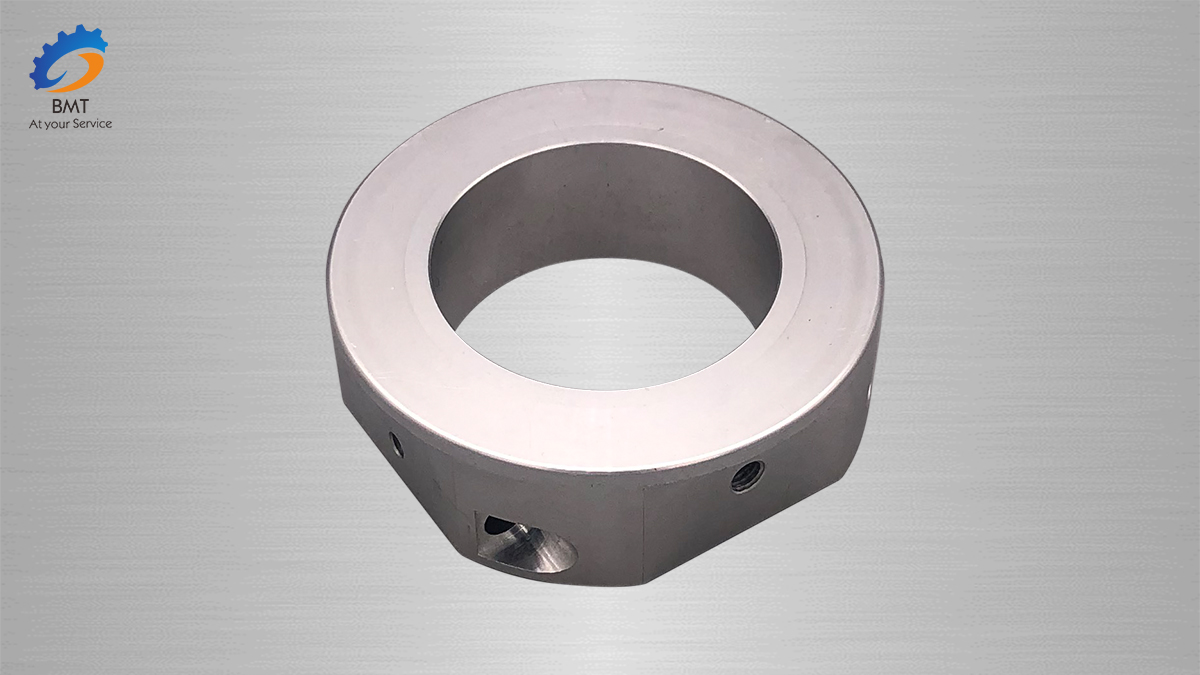

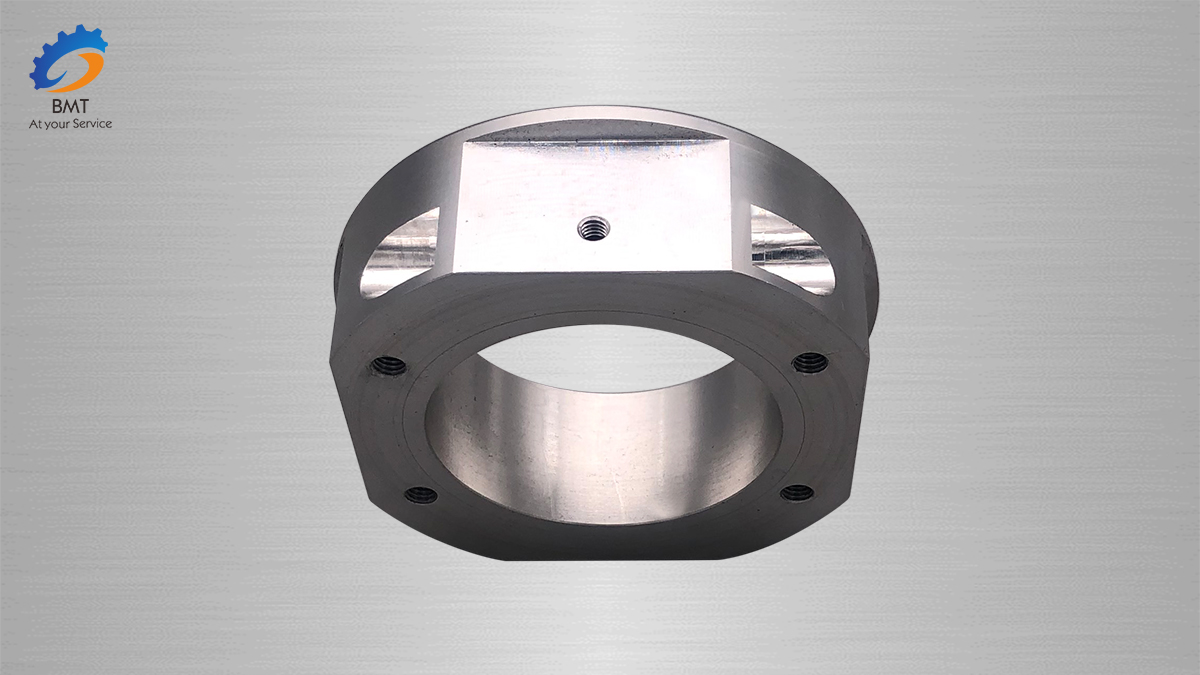

Izingxenye ze-Aluminium CNC Machining

-

I-Aluminium Sheet Metal Fabrication

-

I-Axis High Precision CNC Machining Izingxenye

-

Izingxenye Zomshini ze-CNC zase-Italy

-

CNC Machining Aluminium Izingxenye

-

Auto Parts Machining

-

I-Titanium Alloy Forgings

-

I-Titanium ne-Titanium Alloy Fittings

-

I-Titanium ne-Titanium Alloy Forgings

-

Izintambo ze-Titanium ne-Titanium Alloy

-

Amabha we-Titanium

-

Amapayipi/Amashubhu angenamthungo e-Titanium

-

I-Titanium Welded Pipes/Amashubhu