Amapayipi we-Titanium Angenamthungo namashubhu

I-Gr1, Gr 2, Gr 3 zonke ziyi-titanium ehlanzekile yezimboni. Zinezakhiwo eziphakeme zemishini, ukusebenza kahle kakhulu kokunyathela, futhi zingashiselwa ngezindlela ezihlukahlukene. Amandla okuhlanganiswa okuhlanganisiwe angafinyelela ku-90% wamandla ensimbi eyisisekelo, futhi ukusebenza kokusika kuhle. I-Titanium tube inokumelana nokugqwala okuphezulu ku-chloride, i-sulfide ne-ammonia. Ukumelana nokugqwala kwe-titanium emanzini olwandle kungaphezulu kwalokho kwama-alloys e-aluminium, insimbi engagqwali, nama-alloys asekelwe ku-nickel. I-Titanium futhi imelana nomthelela wamanzi.

Ingxubevange ye-Titanium isetshenziselwa ikakhulukazi ukukhiqizwa kwezingxenye ze-compressor injini yendiza, ilandelwa izingxenye zesakhiwo samarokhethi, imicibisholo nezindiza ezinesivinini esikhulu. Maphakathi nawo-1960, i-titanium nama-alloys ayo iye yasetshenziswa embonini evamile ukwenza ama-electrode embonini yokuhlanza ugesi, ama-condenser eziteshini zikagesi, izifudumezi zokuhluza uphethiloli nokukhipha usawoti emanzini olwandle, kanye nemishini yokulawula ukungcoliswa kwemvelo. I-Titanium nama-alloys ayo isiwuhlobo lwezakhiwo ezimelana nokugqwala. Ngaphezu kwalokho, ibuye isetshenziswe ekukhiqizeni izinto zokugcina i-hydrogen kanye nama-alloys enkumbulo yokuma.

Uma kuqhathaniswa nezinye izinto zensimbi, i-titanium alloy inezinzuzo ezilandelayo:

- Amandla athize aphezulu (amandla okudonsa kanzima/ukuminyana), amandla okuqina angafinyelela ku-100~140kgf/mm2, kanti ukuminyana kungama-60% kuphela ensimbi.

- Izinga lokushisa eliphakathi linamandla amahle, izinga lokushisa lokusetshenziswa lingamadigri angamakhulu amaningana ngaphezu kwalelo lengxubevange ye-aluminium, lingakwazi ukugcina amandla adingekayo ekushiseni okuphakathi, futhi lingasebenza isikhathi eside ekushiseni okungama-450 ~ 500℃.

- Ukumelana nokugqwala okuhle. Ifilimu eyiyunifomu neminyene ye-oxide yenziwa ngokushesha phezu kwe-titanium emkhathini, enekhono lokumelana nokugqwala yimithombo yezindaba ehlukahlukene. Ngokuvamile, i-titanium inokumelana nokugqwala okuhle emithonjeni ye-oxidizing nengathathi hlangothi, futhi inokumelana nokugqwala okungcono emanzini olwandle, i-chlorine emanzi nezixazululo ze-chloride. Kodwa ekunciphiseni imidiya, njenge-hydrochloric acid nezinye izixazululo, ukumelana nokugqwala kwe-titanium kubi.

- Ama-alloys e-Titanium anokusebenza okuhle kwezinga lokushisa eliphansi kanye nezinto eziphansi kakhulu ze-interstitial, njenge-Gr7, angagcina izinga elithile lepulasitiki kokuthi -253℃.

- I-modulus ye-elasticity iphansi, i-thermal conductivity incane, futhi ayiyona i-ferromagnetic.

I-BMT ikhethekile ekuthumeleni amapayipi e-titanium angenamthungo namashubhu, futhi inomkhiqizo wonyaka wamathani angu-5,000. Amapayipi namashubhu angenamthungo e-BMT afaka amandla akhethekile aphezulu, ukumelana nokugqwala, impahla enhle ye-cryogenic, i-modulus enwebekayo ephansi, i-thermal conductivity ephansi futhi ayikho i-ferromagnetism.

Uhlu lwe-BMT lwepayipi le-titanium elingenamthungo neshubhu lithengiswa kabanzi emhlabeni jikelele. Ukugadwa okuqondile kwenziwa ngokwekhwalithi, okuhlanganisa ukuhlaziywa kwengxenye yekhemikhali, ukuhlolwa komfutho womoya, ukuhlola okungonakalisi, ukuhlolwa kwamanje kwe-eddy kanye nokuhlolwa kwe-ultrasonic. Siphinde sibe ne-mechanical testing, emboza i-tensile test, test flaring, test flattening, test ferroxyl, RT, X-Ray test, njll.

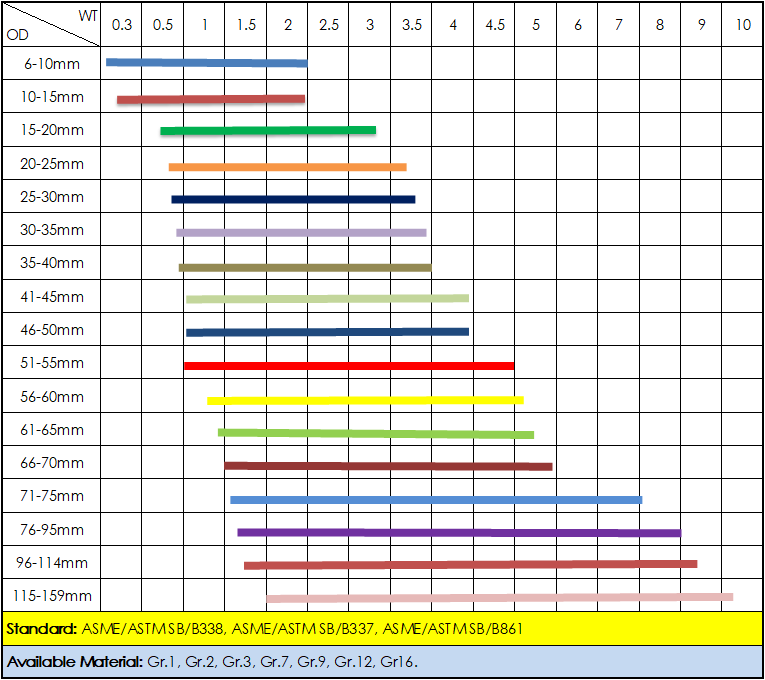

Amapayipi Angenamthungo we-Titanium kanye Nobubanzi Bosayizi Bamashubhu:

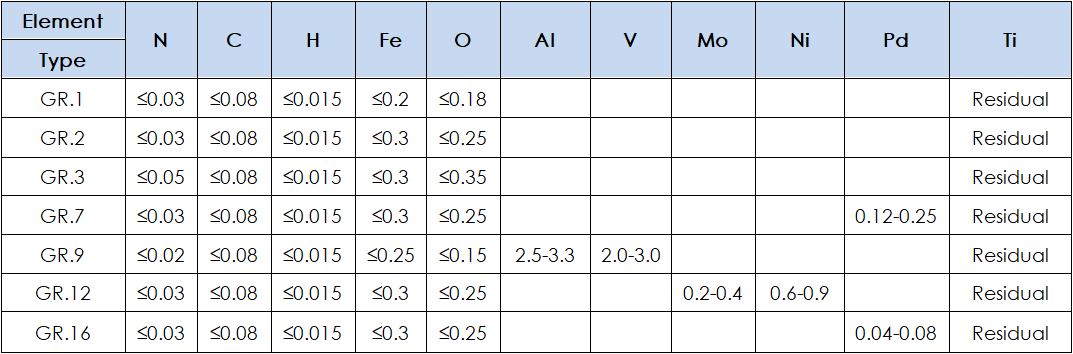

Ukwakheka Kwekhemikhali Okutholakalayo:

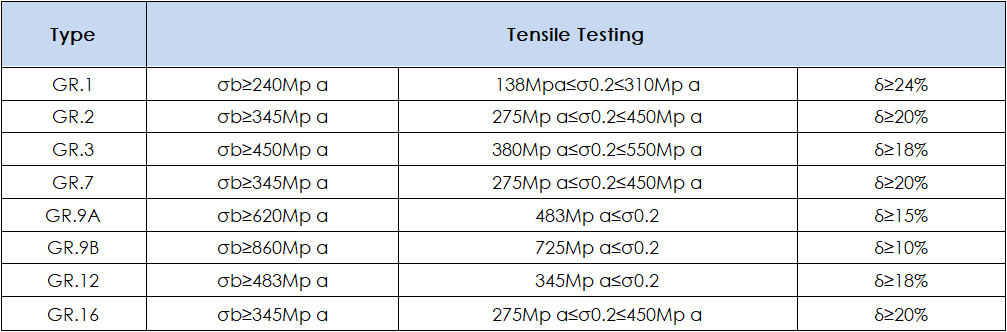

Impahla Etholakalayo Yemishini:

Ukuhlolwa kokuhlola:

- Ukuhlaziywa Kokwakheka Kwamakhemikhali

- Ukuhlolwa Kwempahla Yemishini

- Ukuhlolwa kwe-Tensile

- Ukuhlolwa kwe-Flaring

- Ukuhlola Ukucaba

- Ukugoba Test

- Ukuhlolwa kwe-Hydro-Static

- I-Pneumatic Test (Ukuhlolwa kwengcindezi yomoya ngaphansi kwamanzi)

- Ukuhlolwa kwe-NDT

- Ukuhlolwa Kwamanje kwe-Eddy

- Ukuhlolwa kwe-Ultrasonic

- Ukuhlolwa kwe-LDP

- Ukuhlolwa kwe-Ferroxyl

Ukukhiqiza (Inani Eliphezulu nelincane Le-oda):Unlimited, ngokusho oda.

Isikhathi esiholayo:Isikhathi sokuhola esijwayelekile izinsuku ezingama-30. Nokho, kuya ngenani le-oda ngokufanele.

Ezokuthutha:Indlela evamile yokuhamba ingoLwandle, ngoMoya, nge-Express, ngeSitimela, esizokhethwa ngamakhasimende.

Ukupakisha:

- Ipayipi ligcina livikelwe ngamakepisi epulasitiki noma amakhadibhodi.

- Konke ukufakwa kufanele kupakishwe ukuvikela iziphetho nokubheke.

- Zonke ezinye izimpahla zizopakishwa ngamaphedi amagwebu kanye nokupakishwa kwepulasitiki okuhlobene namakesi e-plywood.

- Noma iziphi izinkuni ezisetshenziselwa ukupakisha kufanele zifaneleke ukuvimbela ukungcola ngokuthintana nemishini yokubamba.