Amabha e-Titanium ne-Titanium Alloy

Ama-alloys e-Titanium angahlukaniswa abe izigaba ezintathu ngokuvumelana nokwakheka kwezigaba: i-alloy α, (α+β) ingxubevange kanye ne-β alloy, evezwa ngokulandelana yi-TA, TC kanye ne-TB eShayina.

① Ingxubevange engu-α iqukethe inani elithile lezinto ezinesigaba esingu-α ezinzile futhi ikakhulukazi yakhiwe isigaba esingu-α esimweni sokulingana. Ama-alloys e-α ane-gravity encane ethize, amandla amahle okushisa, ukushisela okuhle kanye nokumelana nokugqwala okuhle kakhulu. Ukungalungi amandla aphansi ekamelweni lokushisa, futhi ngokuvamile asetshenziswa njengezinto ezivimbela ukushisa kanye nezinto ezivimbela ukugqwala.Ngokujwayelekile, ama-alloys e-α angahlukaniswa abe ama-alloys aphelele e-α (Ta7), cishe ama-alloys angu-α (Ti-8Al-1Mo-1V) futhi α alloys anezinhlanganisela ezimbalwa (Ti-2.5Cu).

Ingxubevange ye-② (α+β) iqukethe inani elithile lezakhi ezinesigaba esizinzile sika-α nesigaba sika-β, futhi i-microstructure yengxubevange esimweni sokulingana iyisigaba esingu-α kanye nesigaba esingu-β.Ingxubevange (α+β) inamandla amaphakathi futhi ingaba kuqiniswe ukwelashwa okushisa, kodwa ukushisela kumpofu.(α+ β) ama-alloys asetshenziswa kakhulu, futhi ukukhishwa kwe-Ti-6Al-4V alloys kubala ngaphezu kwengxenye yazo zonke izinto ze-titanium.

① Ingxubevange ye-β iqukethe inani elikhulu lezakhi ezizinzile esigabeni sika-β, izinga lokushisa eliphakeme elingu-β lingagcinwa kuzinga lokushisa elilingana negumbi.β ingxubevange ingahlukaniswa ibe ingxube ye-β elaphekayo (ingxube ye-metastable ne-β alloy ecishe ibe yi-metastable) kanye nengxubevange yokushisa engu-β. I-β alloy ekwazi ukumelana nokushisa ine-ductility enhle kakhulu esimweni sokucisha futhi ingakwazi ukuzuza amandla e-tensile angu-130~140kgf/mm2 ngokwelashwa kokuguga.Ama-β alloy avame ukusetshenziswa njengamandla aphezulu kanye nezinto eziqinile. ukusebenza, ubunzima bomshini.

Izindinganiso zokucaphuna

1: GB 228 Izindlela zokuhlola ze-Metallic tensile

2: GB/T 3620.1 Ibanga le-Titanium ne-titanium alloy kanye nokwakheka kwamakhemikhali

3: I-GB/T3620.2 i-titanium ne-titanium alloy processing imikhiqizo ukwakheka kwamakhemikhali nokwakheka ukuchezuka okuvumelekile

Izindlela ze-GB 4698 zokuhlaziya amakhemikhali we-titanium sponge, i-titanium ne-titanium alloys

I-GB: GB/T2965-2007, GB/T13810, Q/BS5331-91

Izinga laseMelika: ASTM B348, ASTM F136, ASTM F67, AMS4928

Izidingo zobuchwepheshe

1: Ukwakhiwa kwamakhemikhali we-titanium ne-titanium alloy bar kuzohambisana nezinhlinzeko ze-GB/T 3620.1. Uma kudingeka ukuhlola okuphindaphindiwe, ukuchezuka okuvunyelwe kokwakheka kwamakhemikhali kuzohambisana nezinhlinzeko ze-GB/T 3620.2.

2: Ububanzi noma ubude obuhlangothini bebha yokusebenza okushisayo kanye nokuchezuka kwayo okuvunyelwe kuzohambisana nezinhlinzeko eziseThebulani loku-1.

3: Ngemva kokusebenza okushisayo, ukuchezuka kobubanzi obuvunyelwe bebha edonswa ngokubanda kuzohambisana nezinhlinzeko eziseThebula 2 ngemva kokugingqa (ukugaya) ibha epholishiwe nokugoqeka okubandayo.

I-4: ngemuva kokucubungula okushisayo ngemoto (yokugaya) ibha yokukhanya ye-roundness akufanele ibe ngaphezu kwesigamu sokubekezelela usayizi wayo.

5: ubude bobude obunganqunyiwe bebha yombuso ecutshunguliwe bungu-300-6000mm, ubude bobude obunganqunyiwe bebha yezwe ehlanganisiwe bungu-300-2000mm, futhi ubude bobude obunqunyiwe noma ubude obuphindwe kabili kufanele bube phakathi kwebanga lobude obunganqunyelwe. .Ukuchezuka okuvunyelwe kobude obulungisiwe kungu-+20mm; Ubude bobude obuphindwe kabili futhi buzofakwa enanini elisikiwe lebha, futhi inani elisikiwe ngalinye lizoba ngu-5mm. Ubude bobude obunqunyiwe noma ubude bobude obuphindwe kabili buzocaciswa kunkontileka.

Imininingwane: ukugoqa ¢8.0-- 40mm× L; Ukuqamba ¢40-150 - mm x L

Isakhiwo se-metallographic: usayizi wokusanhlamvu we-titanium omsulwa awukho ngaphansi kwebanga lesi-5, i-TC4 titanium alloy ngokuhambisana ne-A1-A9.

Ubuso: indawo emnyama, indawo epholishiwe, indawo epholishiwe (H11, H9, H8)

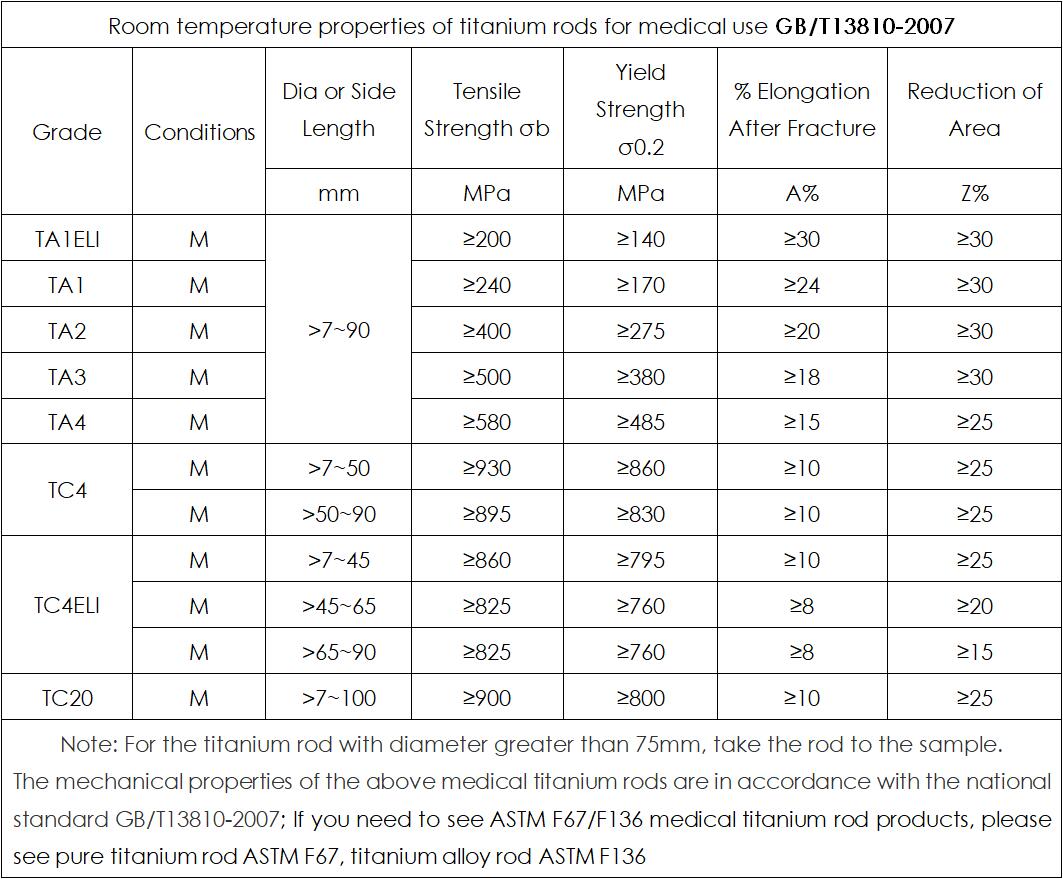

Ukusebenza kwenduku ye-titanium yezokwelapha (okujwayelekile okuyinkomba :GB/T13810-2007,ASTM F67/F136).

Sikhiqiza futhi sithekelisa ibha ye-titanium ejwayelekile ye-ASTM kanye nebha ye-titanium ejwayelekile yase-Chinese (GB), kanye nebha ye-titanium yezinga okuvunyelwene ngalo.

Njengoba singabanye abakhiqizi abambalwa abakwazi ukulawula ikhwalithi kuyo yonke inqubo yokukhiqiza, senza ukulawula okuqinile kwekhwalithi kusukela ekuncibilikisweni kwempahla eluhlaza kwesipontshi se-titanium kuya emikhiqizweni ephelile.

Njengoba sinekhwalithi ephezulu kanye nokulandela umkhondo kanye nesevisi enhle, sithengisa imikhiqizo ehlanganisa ibha ye-titanium yezokwelapha, ibha yokupholisha i-titanium kanye ne-titanium alloy bar emhlabeni jikelele. Sesibe ngomunye wabahlinzeki abakhulu nabathumela ngaphandle kwebha ye-titanium eChina.

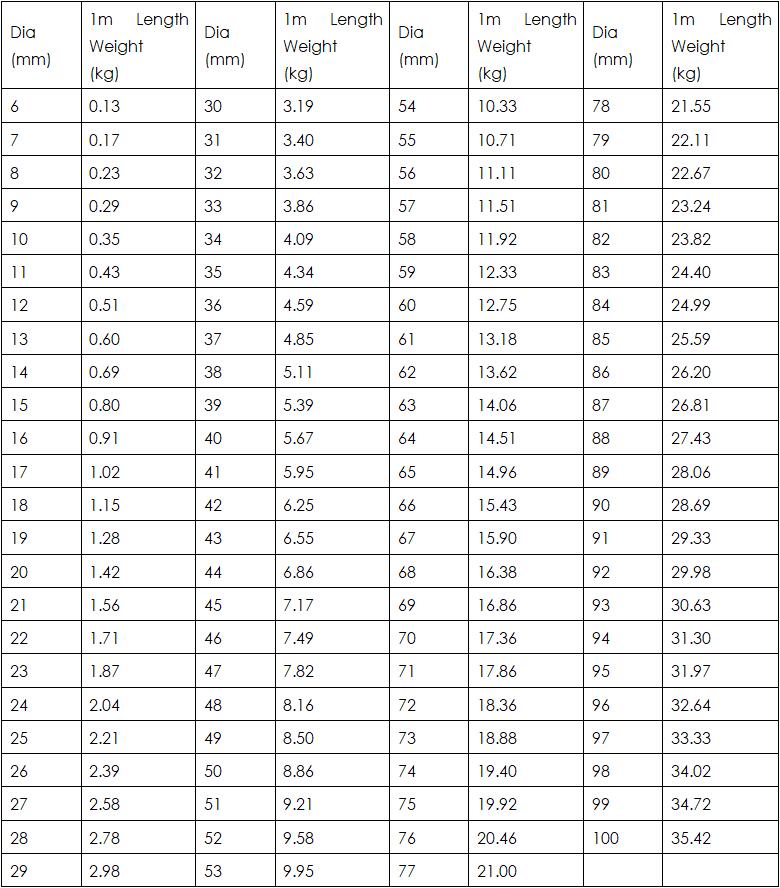

Ibanga losayizi: Ububanzi 6-200mm x Max 6000mm

Izakhiwo zokushisa kwegumbi zezinduku ze-titanium zokusetshenziswa kwezokwelapha GB/T13810-2007:

Osayizi Esiwenzile:

Ubukhulu, Ukubekezelelana kanye ne-Ovality Range:

Ukwakheka Kwekhemikhali Okutholakalayo

Ukwakheka Kwekhemikhali Okutholakalayo

Ukuhlolwa kokuhlola:

- Ukuhlolwa kwe-NDT

- Ukuhlolwa kwe-Ultrasonic

- Ukuhlolwa kwe-LDP

- Ukuhlolwa kwe-Ferroxyl

Ukukhiqiza (Inani Eliphezulu nelincane Le-oda):Unlimited, ngokusho oda.

Isikhathi esiholayo:Isikhathi sokuhola esijwayelekile izinsuku ezingama-30. Nokho, kuya ngenani le-oda ngokufanele.

Ezokuthutha:Indlela evamile yokuhamba ingoLwandle, ngoMoya, nge-Express, ngeSitimela, esizokhethwa ngamakhasimende.

Ukupakisha:

- Ipayipi ligcina livikelwe ngamakepisi epulasitiki noma amakhadibhodi.

- Konke ukufakwa kufanele kupakishwe ukuvikela iziphetho nokubheke.

- Zonke ezinye izimpahla zizopakishwa ngamaphedi amagwebu kanye nokupakishwa kwepulasitiki okuhlobene namakesi e-plywood.

- Noma iziphi izinkuni ezisetshenziselwa ukupakisha kufanele zifaneleke ukuvimbela ukungcola ngokuthintana nemishini yokubamba.