I-Titanium Alloy CNC Machining

Umshini wokucindezela we-titanium alloys ufana kakhulu nomshini wensimbi kunezinsimbi ezingenayo insimbi nama-alloys. Izinqubo eziningi zamapharamitha we-titanium alloys ekufojini, ukugxiviza ivolumu nokugxiviza amashidi ziseduze nalezo ezicutshungulwa ngensimbi. Kodwa kunezici ezithile ezibalulekile okufanele zibhekwe lapho ucindezela ukusebenza kwe-Chin and Chin alloys.

Nakuba ngokuvamile kukholakala ukuthi ama-lattice angama-hexagonal aqukethwe ku-titanium ne-titanium alloys ane-ductile encane lapho ekhubazekile, izindlela ezihlukahlukene zokusebenza zomshini ezisetshenziselwa ezinye izinsimbi zesakhiwo nazo zifanelekile kuma-alloys e-titanium. Isilinganiso sephuzu lesivuno kuya kumkhawulo wamandla singenye yezinkomba ezibonisa ukuthi insimbi ingakwazi yini ukumelana nokuguqulwa kwepulasitiki. Uma lesi silinganiso sikhulu, sibi kakhulu ipulasitiki yensimbi. Ku-titanium emsulwa ngokwezimboni endaweni epholile, isilinganiso singu-0.72-0.87, uma siqhathaniswa no-0.6-0.65 wensimbi ye-carbon kanye no-0.4-0.5 wensimbi engagqwali.

Yenza isitembu sevolumu, ukufoja kwamahhala nokunye okuhlobene nokucutshungulwa kwezikhala ezinkulu ze-cross-section kanye nosayizi abakhulu esimweni esishisayo (ngaphezu kwezinga lokushisa = yS). Izinga lokushisa lokushisa lokubumba nokugxiviza liphakathi kuka-850-1150°C. Ama-alloys BT; I-M0, BT1-0, OT4~0 kanye ne-OT4-1 zinokushintshashintsha kwepulasitiki okwanelisayo esimweni esipholile. Ngakho-ke, izingxenye ezenziwe ngalawa ma-alloys ngokuvamile zenziwe ngezikhala eziphakathi nendawo ngaphandle kokufudumeza nokugxiviza. Lapho ingxubevange ye-titanium ibanda epulasitiki ikhubazekile, kungakhathaliseki ukuthi ukwakheka kwayo kwamakhemikhali kanye nezakhiwo zemishini, amandla azothuthukiswa kakhulu, futhi ipulasitiki izoncishiswa ngokufanayo. Ngenxa yalesi sizathu, ukwelashwa kwe-annealing phakathi kwezinqubo kufanele kwenziwe.

Ukuguga kwe-insert groove ekukhiqizeni ama-alloys e-titanium ukuguga kwendawo ngemuva nangaphambili lapho kuqondiswa khona ukujula kokusikwa, okuvame ukubangelwa ungqimba oluqinile olushiywe ukucutshungulwa kwangaphambilini. Ukusabela kwamakhemikhali kanye nokusabalalisa kwethuluzi kanye nezinto zokusebenza endaweni yokushisa yokucubungula engaphezu kuka-800 °C nakho kungesinye sezizathu zokwakheka kokugqoka kwe-groove. Ngoba ngesikhathi senqubo yomshini, ama-molecule e-titanium we-workpiece aqoqana phambi kwe-blade futhi "ahlanganiswe" emaphethelweni e-blade ngaphansi kwengcindezi ephakeme kanye nokushisa okuphezulu, okwenza unqenqema olwakhiwe. Lapho unqenqema olwakhiwe luhlakaza onqenqemeni lokusika, isambatho se-carbide sokufaka siyasuswa.

Ngenxa yokumelana nokushisa kwe-titanium, ukupholisa kubalulekile enqubweni yokwenza imishini. Inhloso yokupholisa ukugcina unqenqema kanye nendawo yamathuluzi ekushiseni ngokweqile. Sebenzisa i-end coolant ukuze ukhiphe ama-chip aphelele lapho ugaya amahlombe kanye namaphakethe okugaya ubuso, amaphakethe noma imifantu egcwele. Uma usika insimbi ye-titanium, ama-chips kulula ukunamathela onqenqemeni lokusika, okubangela umjikelezo olandelayo we-milling cutter ukuthi usike ama-chips futhi, ngokuvamile okubangela ukuthi umugqa onqenqemeni uhlehle.

Imbobo ngayinye yokufaka inembobo/umjovo wayo wokupholisa ukuze kuxazululwe le nkinga futhi kuthuthukiswe ukusebenza konqenqema okungaguquki. Esinye isixazululo esihlanzekile yizimbobo zokupholisa ezinentambo. Abasiki bemilling emaphethelweni amade banokufaka okuningi. Ukufaka isipholile emgodini ngamunye kudinga umthamo wepompo ephezulu kanye nokucindezela. Ngakolunye uhlangothi, ingaxhuma izimbobo ezingadingeki njengoba kudingeka, ngaleyo ndlela ikhulise ukugeleza emigodini edingekayo.

Thumela umlayezo wakho kithi:

-

Izingxenye ze-Aluminium CNC Machining

-

I-Aluminium Sheet Metal Fabrication

-

I-Axis High Precision CNC Machining Izingxenye

-

Izingxenye Zomshini ze-CNC zase-Italy

-

CNC Machining Aluminium Izingxenye

-

Auto Parts Machining

-

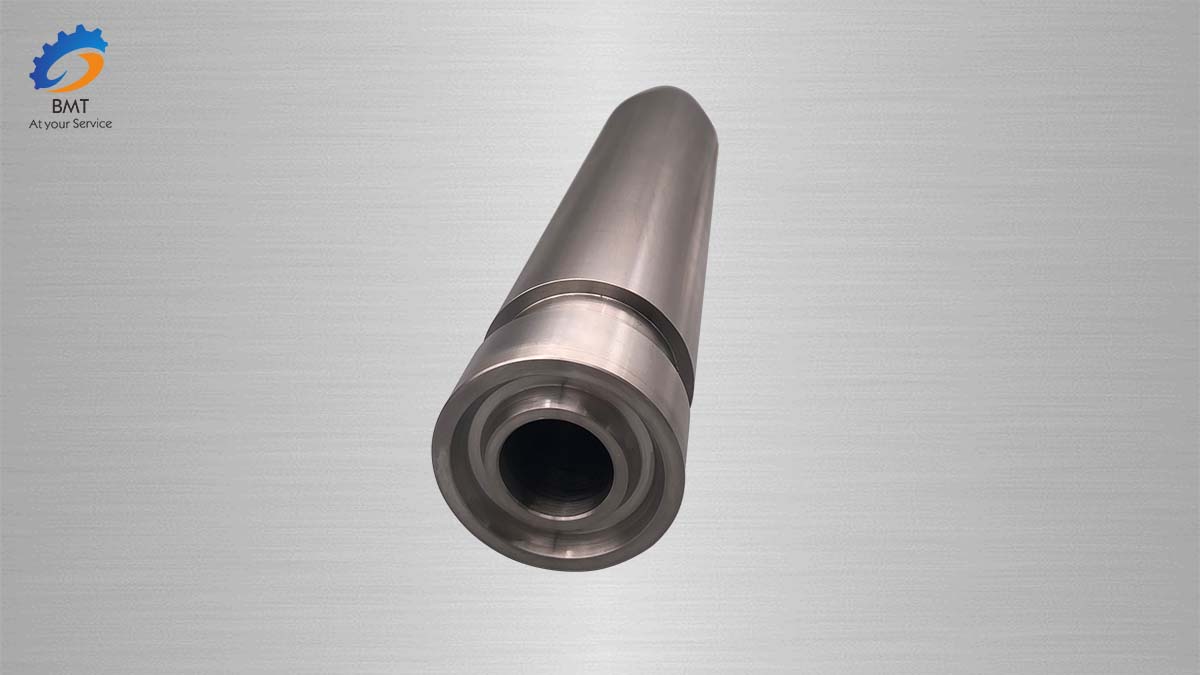

I-Titanium Alloy Forgings

-

I-Titanium ne-Titanium Alloy Fittings

-

I-Titanium ne-Titanium Alloy Forgings

-

Izintambo ze-Titanium ne-Titanium Alloy

-

Amabha we-Titanium

-

Amapayipi/Amashubhu angenamthungo e-Titanium

-

I-Titanium Welded Pipes/Amashubhu