Izakhiwo ze-Titanium Alloy Mechanical

Ingxubevange ye-Titanium inamandla aphezulu kanye nokuminyana okuphansi, izakhiwo ezinhle zemishini, ukuqina okuhle nokumelana nokugqwala. Ngaphezu kwalokho, ukusebenza kwenqubo ye-titanium alloy kumpofu, ukusika kunzima, ekucutshungulweni okushisayo, kulula kakhulu ukumunca i-hydrogen oxygen nitrogen carbon nokunye ukungcola. Kukhona ukungagugi kahle, inqubo yokukhiqiza eyinkimbinkimbi. Ukukhiqizwa kwezimboni ze-titanium kwaqala ngo-1948. Ukuthuthukiswa kwezidingo zemboni yezindiza, ukuze imboni ye-titanium ngesilinganiso sokukhula sonyaka esingaba ngu-8%.

Njengamanje, umkhiqizo wonyaka we-titanium alloy processing material emhlabeni usufinyelele amathani angaphezu kuka-40,000, kanye nezinhlobo ezingaba ngu-30 zamamaki e-titanium alloy. Ama-titanium alloys asetshenziswa kakhulu yi-Ti-6Al-4V(TC4), Ti-5Al-2.5Sn(TA7) kanye ne-industrial pure titanium (TA1, TA2 ne-TA3).

Ama-alloys e-Titanium asetshenziswa kakhulu ukwenza izingxenye ze-compressor zezinjini zezindiza, zilandelwa izingxenye zesakhiwo zamarokhethi, imicibisholo nezindiza ezinesivinini esikhulu. Maphakathi nawo-1960, i-titanium nama-alloys ayo kwase kusetshenziswe embonini evamile ukwenza ama-electrode e-electrolysis, ama-condenser eziteshini zikagesi, izifudumezi zokucwenga uwoyela nokukhipha usawoti emanzini, kanye nemishini yokulawula ukungcola. I-Titanium nama-alloys ayo isiphenduke uhlobo lokugqwala - izinto zokwakha ezimelana nazo. Ngaphezu kwalokho, iphinde isetshenziselwe ukukhiqiza izinto zokugcina i-hydrogen kanye nokubumba ama-alloys enkumbulo.

I-China yaqala ucwaningo nge-titanium ne-titanium alloys ngo-1956; Maphakathi nawo-1960, ukukhiqizwa kwezimboni ze-titanium kanye nokuthuthukiswa kwe-TB2 alloy kwaqala. I-Titanium alloy yinto entsha ebalulekile yesakhiwo esetshenziswa embonini ye-aerospace. Amandla adonsela phansi athile, amandla kanye nezinga lokushisa lesevisi kuphakathi kwe-aluminium nensimbi, kodwa amandla ayo athile aphezulu futhi inokugqwala okuhle kakhulu okulwa namanzi olwandle kanye nokusebenza kwezinga lokushisa eliphansi kakhulu.

Ngo-1950, i-F-84 fighter-bomber yaqala ukusetshenziswa njengesihlangu sokushisa esingemuva se-fuselage, i-air hood, i-tail hood, nezinye izinto ezingathwali. Kusukela ngeminyaka yawo-1960s, ukusetshenziswa kwe-titanium alloy kuye kwasuswa ku-fuselage engemuva kwayiswa ku-fuselage ephakathi, kushintsha ingxenye yensimbi yesakhiwo ukwenza izingxenye ezibalulekile zokuthwala ezifana nohlaka, i-beam kanye ne-flap slide. Ukusetshenziswa kwe-titanium alloy endizeni yezempi kuye kwanda ngokushesha, kwafinyelela ku-20% ~ 25% yesisindo sesakhiwo sendiza.

Thumela umlayezo wakho kithi:

-

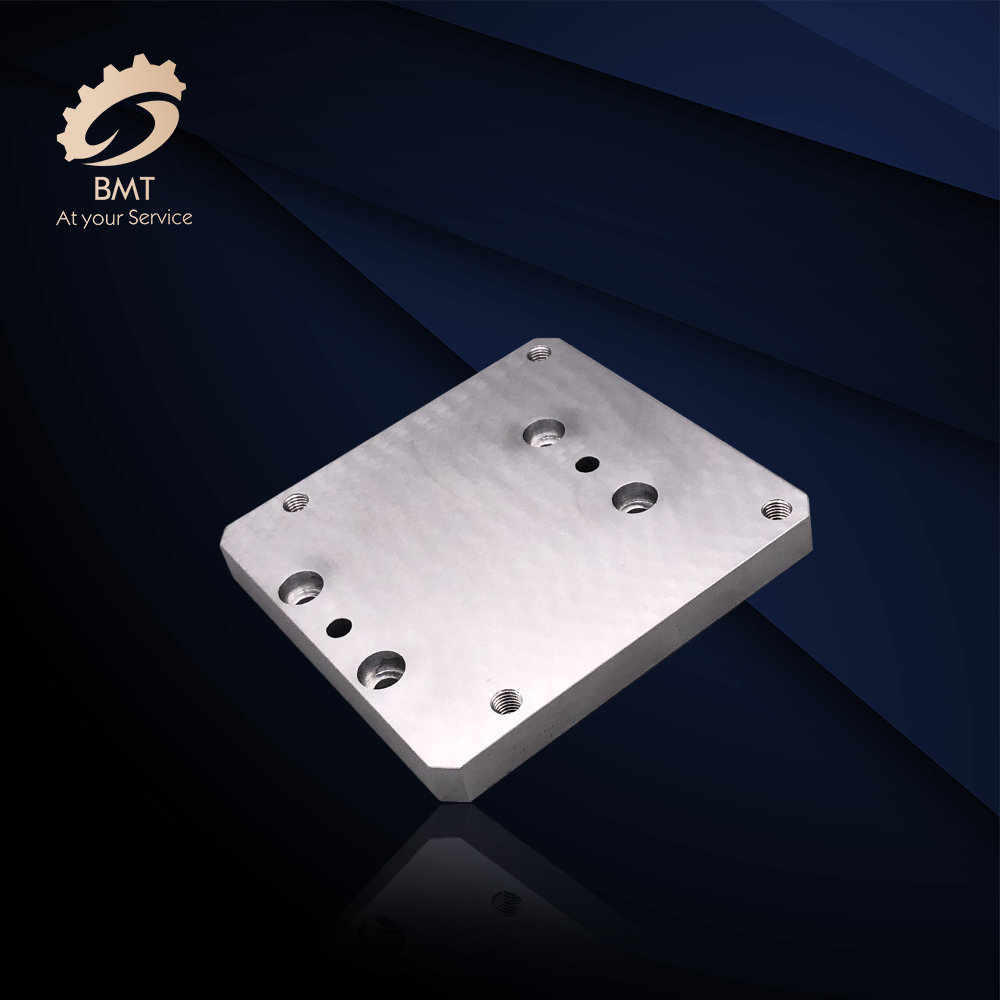

Izingxenye ze-Aluminium CNC Machining

-

I-Aluminium Sheet Metal Fabrication

-

I-Axis High Precision CNC Machining Izingxenye

-

Izingxenye Zomshini ze-CNC zase-Italy

-

CNC Machining Aluminium Izingxenye

-

Auto Parts Machining

-

I-Titanium Alloy Forgings

-

I-Titanium ne-Titanium Alloy Fittings

-

I-Titanium ne-Titanium Alloy Forgings

-

Izintambo ze-Titanium ne-Titanium Alloy

-

Amabha we-Titanium

-

Amapayipi/Amashubhu angenamthungo e-Titanium

-

I-Titanium Welded Pipes/Amashubhu