Konke esikwenzayo kuvame ukuxhunyaniswa ne-tenet yethu ” Iklayenti kuqala kakhulu, Inkolelo kuqala, sinikela mayelana nokupakishwa kwezinto zokudla kanye nokuphepha kwemvelo Ukuthengwa Okukhulu Kwezidili Zanyanga Zonke Izingxenye Zemboni ye-Titanium Alloy, i-OEM eyenziwe ngokwezifiso i-CNC High Precision Machining evela e-China, Siyakwamukela ngokufudumele eduze. abangani abavela kuzo zonke izigaba zempilo yansuku zonke ukuze bafune ukubambisana futhi bakhe ikusasa elihle kakhulu nelibabazekayo.

Konke esikwenzayo kuvame ukuxhunyaniswa ne-tenet yethu ” Iklayenti kuqala kakhulu, Inkolelo kuqala, sinikela mayelana nokupakishwa kwezinto zokudla kanye nokuphepha kwemveloIzingxenye ze-China Auto, Izingxenye ezisele, Siyakwamukela ukuthi uvakashele inkampani yethu nefekthri futhi igumbi lethu lokubonisa libonisa izinto ezihlukahlukene ezizohlangabezana nokulindela kwakho. Okwamanje, kulula ukuvakashela iwebhusayithi yethu. Abasebenzi bethu abathengisayo bazozama ngakho konke okusemandleni abo ukukuhlinzeka ngezinkonzo ezihamba phambili. Uma kufanele ube nolwazi oluthe xaxa, qiniseka ukuthi ungangabazi ukusithinta nge-E-mail, ngefeksi noma ngocingo.

Amabha e-Titanium ne-Titanium Alloy

Ama-alloys e-Titanium angahlukaniswa abe izigaba ezintathu ngokuvumelana nokwakheka kwezigaba: i-alloy α, (α+β) ingxubevange kanye ne-β alloy, evezwa ngokulandelana yi-TA, TC kanye ne-TB eShayina.

① Ingxubevange engu-α iqukethe inani elithile lezinto ezinesigaba esingu-α ezinzile futhi ikakhulukazi yakhiwe isigaba esingu-α esimweni sokulingana. Ama-alloys e-α ane-gravity encane ethize, amandla amahle okushisa, ukushisela okuhle kanye nokumelana nokugqwala okuhle kakhulu. Ukungalungi amandla aphansi ekamelweni lokushisa, futhi ngokuvamile asetshenziswa njengezinto ezivimbela ukushisa kanye nezinto ezivimbela ukugqwala.Ngokujwayelekile, ama-alloys e-α angahlukaniswa abe ama-alloys aphelele e-α (Ta7), cishe ama-alloys angu-α (Ti-8Al-1Mo-1V) futhi α alloys anezinhlanganisela ezimbalwa (Ti-2.5Cu).

Ingxubevange ye-② (α+β) iqukethe inani elithile lezakhi ezinesigaba esizinzile sika-α nesigaba sika-β, futhi i-microstructure yengxubevange esimweni sokulingana iyisigaba esingu-α kanye nesigaba esingu-β.Ingxubevange (α+β) inamandla amaphakathi futhi ingaba kuqiniswe ukwelashwa okushisa, kodwa ukushisela kumpofu.(α+ β) ama-alloys asetshenziswa kakhulu, futhi ukukhishwa kwe-Ti-6Al-4V alloys kubala ngaphezu kwengxenye yazo zonke izinto ze-titanium.

① Ingxubevange ye-β iqukethe inani elikhulu lezakhi ezizinzile esigabeni sika-β, izinga lokushisa eliphakeme elingu-β lingagcinwa kuzinga lokushisa elilingana negumbi.β ingxubevange ingahlukaniswa ibe ingxube ye-β elaphekayo (ingxube ye-metastable ne-β alloy ecishe ibe yi-metastable) kanye nengxubevange yokushisa engu-β. I-β alloy ekwazi ukumelana nokushisa ine-ductility enhle kakhulu esimweni sokucisha futhi ingakwazi ukuzuza amandla e-tensile angu-130~140kgf/mm2 ngokwelashwa kokuguga.Ama-β alloy avame ukusetshenziswa njengamandla aphezulu kanye nezinto eziqinile. ukusebenza, ubunzima bomshini.

Izindinganiso zokucaphuna

1: GB 228 Izindlela zokuhlola ze-Metallic tensile

2: GB/T 3620.1 Ibanga le-Titanium ne-titanium alloy kanye nokwakheka kwamakhemikhali

3: I-GB/T3620.2 i-titanium ne-titanium alloy processing imikhiqizo ukwakheka kwamakhemikhali nokwakheka ukuchezuka okuvumelekile

Izindlela ze-GB 4698 zokuhlaziya amakhemikhali we-titanium sponge, i-titanium ne-titanium alloys

I-GB: GB/T2965-2007, GB/T13810, Q/BS5331-91

Izinga laseMelika: ASTM B348, ASTM F136, ASTM F67, AMS4928

Izidingo zobuchwepheshe

1: Ukwakhiwa kwamakhemikhali we-titanium ne-titanium alloy bar kuzohambisana nezinhlinzeko ze-GB/T 3620.1. Uma kudingeka ukuhlola okuphindaphindiwe, ukuchezuka okuvunyelwe kokwakheka kwamakhemikhali kuzohambisana nezinhlinzeko ze-GB/T 3620.2.

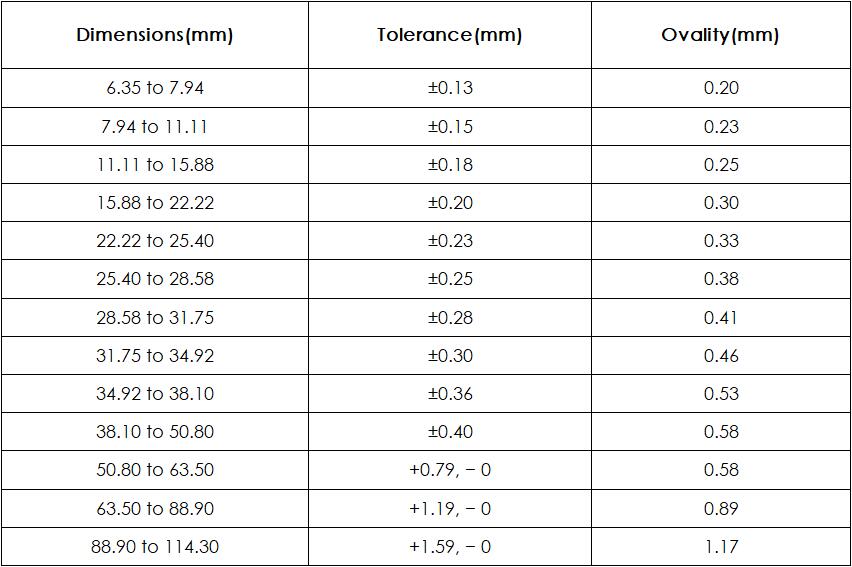

2: Ububanzi noma ubude obuhlangothini bebha yokusebenza okushisayo kanye nokuchezuka kwayo okuvunyelwe kuzohambisana nezinhlinzeko eziseThebulani loku-1.

3: Ngemva kokusebenza okushisayo, ukuchezuka kobubanzi obuvunyelwe bebha edonswa ngokubanda kuzohambisana nezinhlinzeko eziseThebula 2 ngemva kokugingqa (ukugaya) ibha epholishiwe nokugoqeka okubandayo.

I-4: ngemuva kokucubungula okushisayo ngemoto (yokugaya) ibha yokukhanya ye-roundness akufanele ibe ngaphezu kwesigamu sokubekezelela usayizi wayo.

5: ubude bobude obunganqunyiwe bebha yombuso ecutshunguliwe bungu-300-6000mm, ubude bobude obunganqunyiwe bebha yezwe ehlanganisiwe bungu-300-2000mm, futhi ubude bobude obunqunyiwe noma ubude obuphindwe kabili kufanele bube phakathi kwebanga lobude obunganqunyelwe. .Ukuchezuka okuvunyelwe kobude obulungisiwe kungu-+20mm; Ubude bobude obuphindwe kabili futhi buzofakwa enanini elisikiwe lebha, futhi inani elisikiwe ngalinye lizoba ngu-5mm. Ubude bobude obunqunyiwe noma ubude bobude obuphindwe kabili buzocaciswa kunkontileka.

Imininingwane: ukugoqa ¢8.0– 40mm× L; Ukuqamba ¢40-150 – mm x L

Isakhiwo se-metallographic: usayizi wokusanhlamvu we-titanium omsulwa awukho ngaphansi kwebanga lesi-5, i-TC4 titanium alloy ngokuhambisana ne-A1-A9.

Ubuso: indawo emnyama, indawo epholishiwe, indawo epholishiwe (H11, H9, H8)

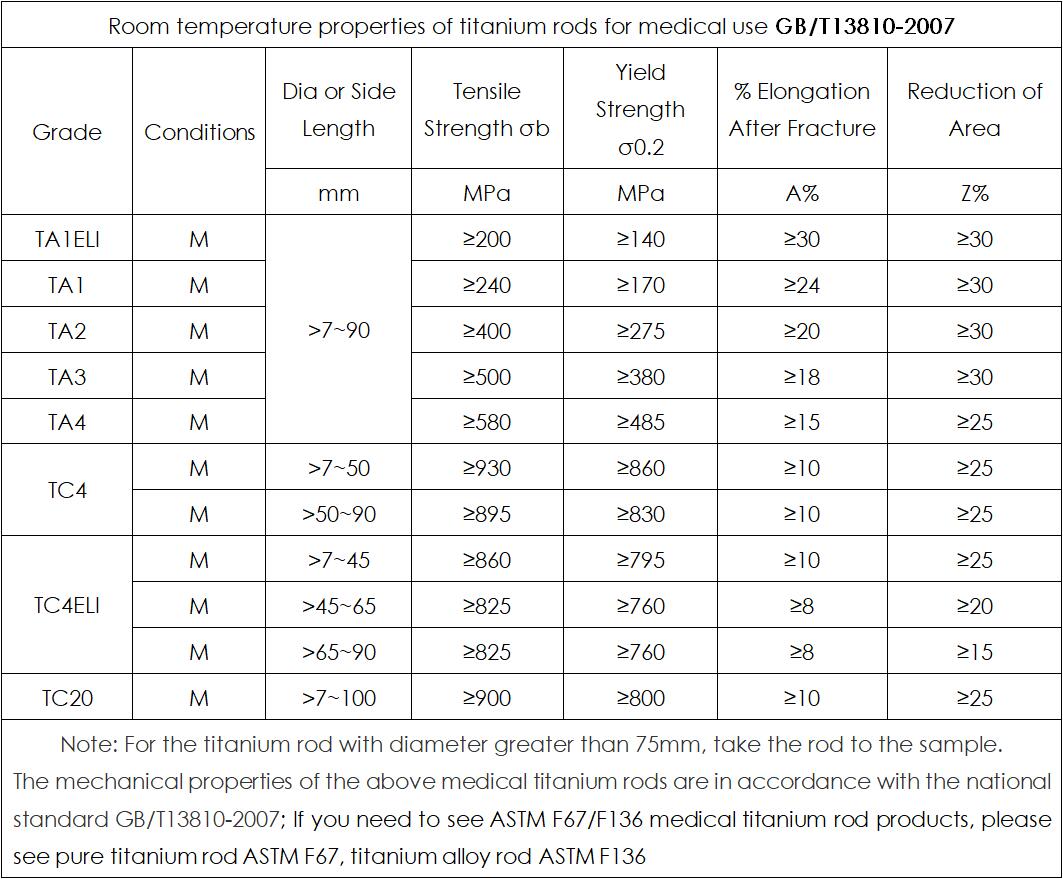

Ukusebenza kwenduku ye-titanium yezokwelapha (okujwayelekile okuyinkomba :GB/T13810-2007,ASTM F67/F136).

Sikhiqiza futhi sithekelisa ibha ye-titanium ejwayelekile ye-ASTM kanye nebha ye-titanium ejwayelekile yase-Chinese (GB), kanye nebha ye-titanium yezinga okuvunyelwene ngalo.

Njengoba singabanye abakhiqizi abambalwa abakwazi ukulawula ikhwalithi kuyo yonke inqubo yokukhiqiza, senza ukulawula okuqinile kwekhwalithi kusukela ekuncibilikisweni kwempahla eluhlaza kwesipontshi se-titanium kuya emikhiqizweni ephelile.

Njengoba sinekhwalithi ephezulu kanye nokulandela umkhondo kanye nesevisi enhle, sithengisa imikhiqizo ehlanganisa ibha ye-titanium yezokwelapha, ibha yokupholisha i-titanium kanye ne-titanium alloy bar emhlabeni jikelele. Sesibe ngomunye wabahlinzeki abakhulu nabathumela ngaphandle kwebha ye-titanium eChina.

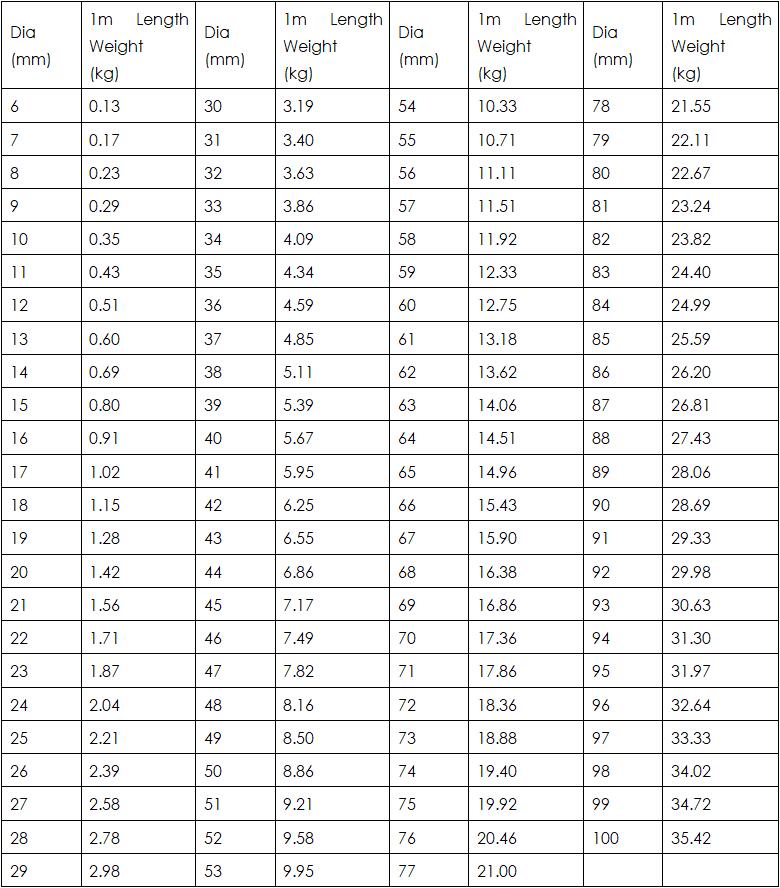

Ibanga losayizi: Ububanzi 6-200mm x Max 6000mm

Izakhiwo zokushisa kwegumbi zezinduku ze-titanium zokusetshenziswa kwezokwelapha GB/T13810-2007:

Osayizi Esiwenzile:

Ubukhulu, Ukubekezelelana kanye ne-Ovality Range:

Ukwakheka Kwekhemikhali Okutholakalayo

Ukwakheka Kwekhemikhali Okutholakalayo

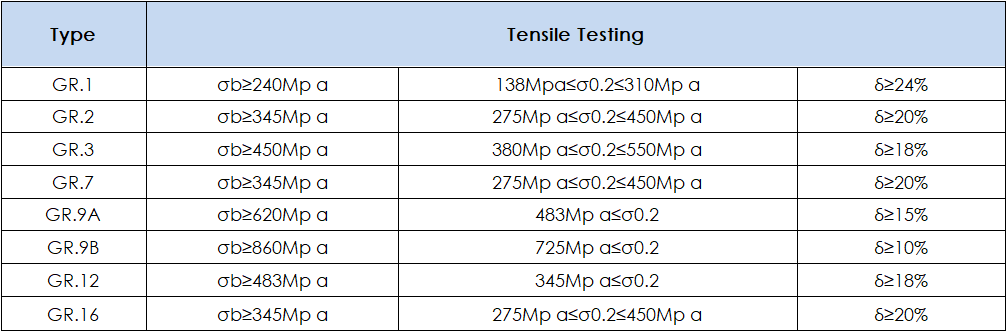

Ukuhlolwa kokuhlola:

- Ukuhlolwa kwe-NDT

- Ukuhlolwa kwe-Ultrasonic

- Ukuhlolwa kwe-LDP

- Ukuhlolwa kwe-Ferroxyl

Ukukhiqiza (Inani Eliphezulu nelincane Le-oda):Unlimited, ngokusho oda.

Isikhathi esiholayo:Isikhathi sokuhola esijwayelekile izinsuku ezingama-30. Nokho, kuya ngenani le-oda ngokufanele.

Ezokuthutha:Indlela evamile yokuhamba ingoLwandle, ngoMoya, nge-Express, ngeSitimela, esizokhethwa ngamakhasimende.

Ukupakisha:

- Ipayipi ligcina livikelwe ngamakepisi epulasitiki noma amakhadibhodi.

- Konke ukufakwa kufanele kupakishwe ukuvikela iziphetho nokubheke.

- Zonke ezinye izimpahla zizopakishwa ngamaphedi amagwebu kanye nokupakishwa kwepulasitiki okuhlobene namakesi e-plywood.

- Noma iziphi izinkuni ezisetshenziselwa ukupakisha kufanele zifaneleke ukuvimbela ukungcola ngokuthintana nemishini yokubamba.

Konke esikwenzayo kuvame ukuxhunyaniswa ne-tenet yethu ” Iklayenti kuqala kakhulu, Inkolelo kuqala, sinikela mayelana nokupakishwa kwezinto zokudla kanye nokuphepha kwemvelo Ukuthengwa Okukhulu Kwezidili Zanyanga Zonke Izingxenye Zemboni ye-Titanium Alloy, i-OEM eyenziwe ngokwezifiso i-CNC High Precision Machining evela e-China, Siyakwamukela ngokufudumele eduze. abangani abavela kuzo zonke izigaba zempilo yansuku zonke ukuze bafune ukubambisana futhi bakhe ikusasa elihle kakhulu nelibabazekayo.

Super Purchasing forIzingxenye ze-China Auto, Izingxenye ezisele, Siyakwamukela ukuthi uvakashele inkampani yethu nefekthri futhi igumbi lethu lokubonisa libonisa izinto ezihlukahlukene ezizohlangabezana nokulindela kwakho. Okwamanje, kulula ukuvakashela iwebhusayithi yethu. Abasebenzi bethu abathengisayo bazozama ngakho konke okusemandleni abo ukukuhlinzeka ngezinkonzo ezihamba phambili. Uma kufanele ube nolwazi oluthe xaxa, qiniseka ukuthi ungangabazi ukusithinta nge-E-mail, ngefeksi noma ngocingo.