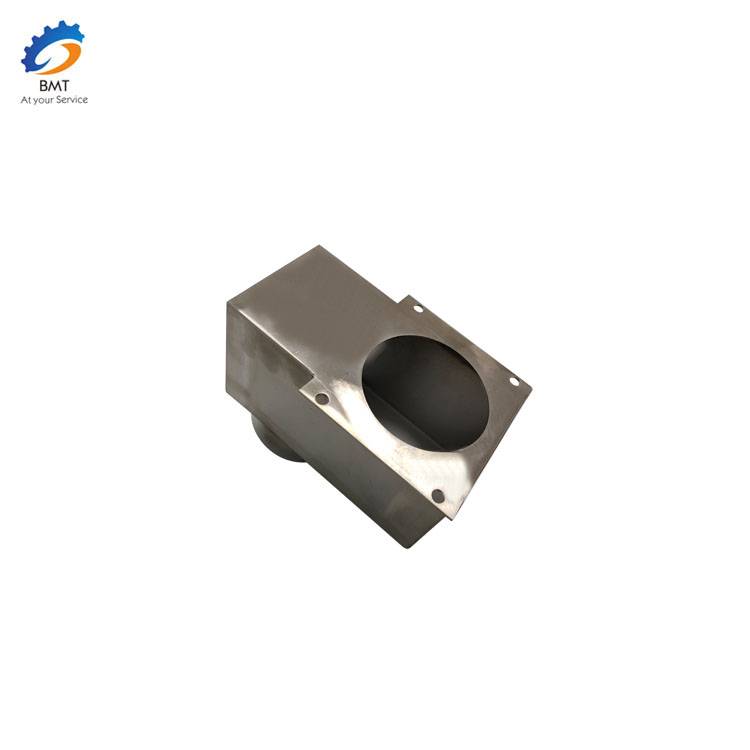

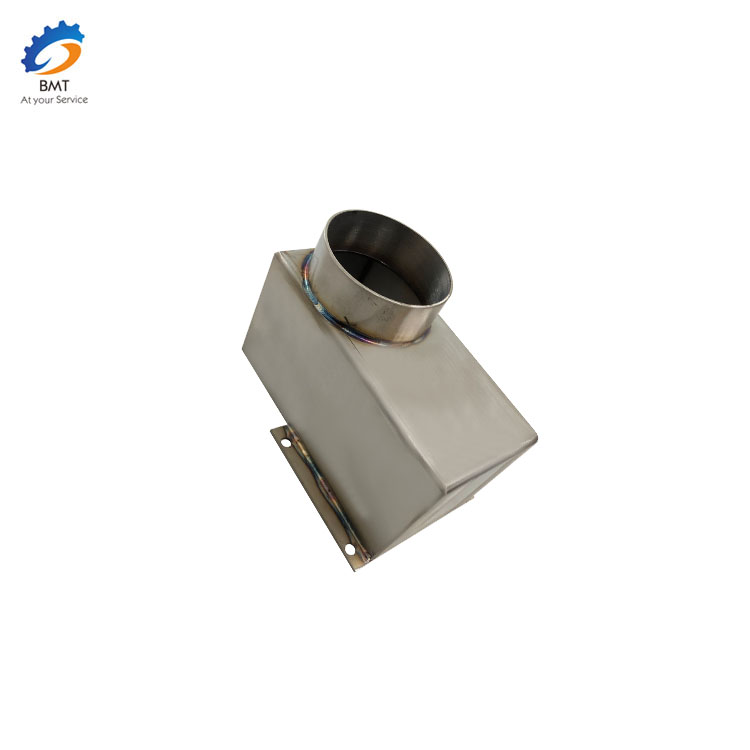

I-Stainless Steel Sheet Metal Working

Izinsizakalo zokwenziwa kwensimbi yangokwezifiso ze-BMT ziyisixazululo esingabizi kakhulu, esidingeka kakhulu sezidingo zakho zokukhiqiza. Izinsizakalo zethu zokwenziwa zisuka kumodeli wevolumu ephansi ziye emisebenzini yokukhiqiza enevolumu ephezulu. Ungahambisa imidwebo yakho ye-2D noma ye-3D ukuze uthole izingcaphuno ezivela kithi ngokuqondile. Siyazi ukuthi isivinini sibalwa; yingakho sikunikeza ukucaphuna okusheshayo kanye nezikhathi zokuhola ngokushesha ezingxenyeni zakho zensimbi zeshidi.

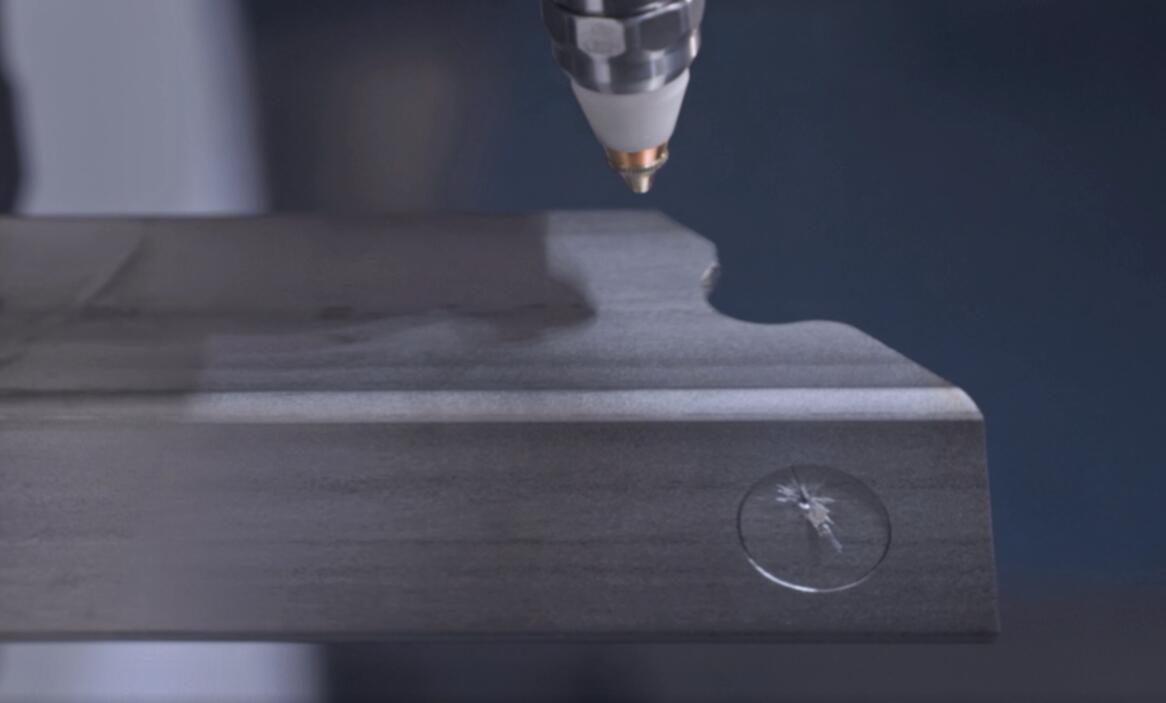

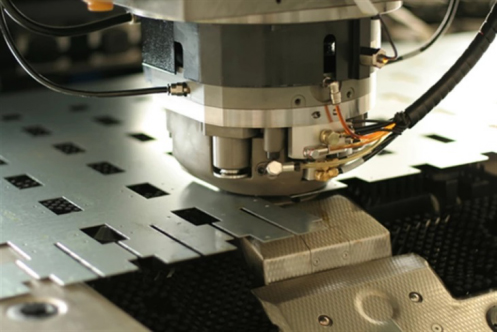

Ukwenziwa kwensimbi yeshidi kuyinqubo yokwenza izingxenye ngeshidi lensimbi. Amafayela akho e-3D CAD aguqulwa abe ikhodi yomshini, elawula umshini osika ngokunembile futhi wakhe amashidi engxenyeni yokugcina. Izingxenye zensimbi zeshidi zaziwa ngokuhlala kwazo isikhathi eside, okuzenza zibe zinhle ekusebenzeni kokusetshenziswa ekugcineni. Izingxenye ezisetshenziselwa ama-prototypes evolumu ephansi kanye nokuqhutshwa kokukhiqizwa kwevolumu ephezulu kubiza kakhulu ngenxa yokusetha kokuqala okukhulu nezindleko zempahla.

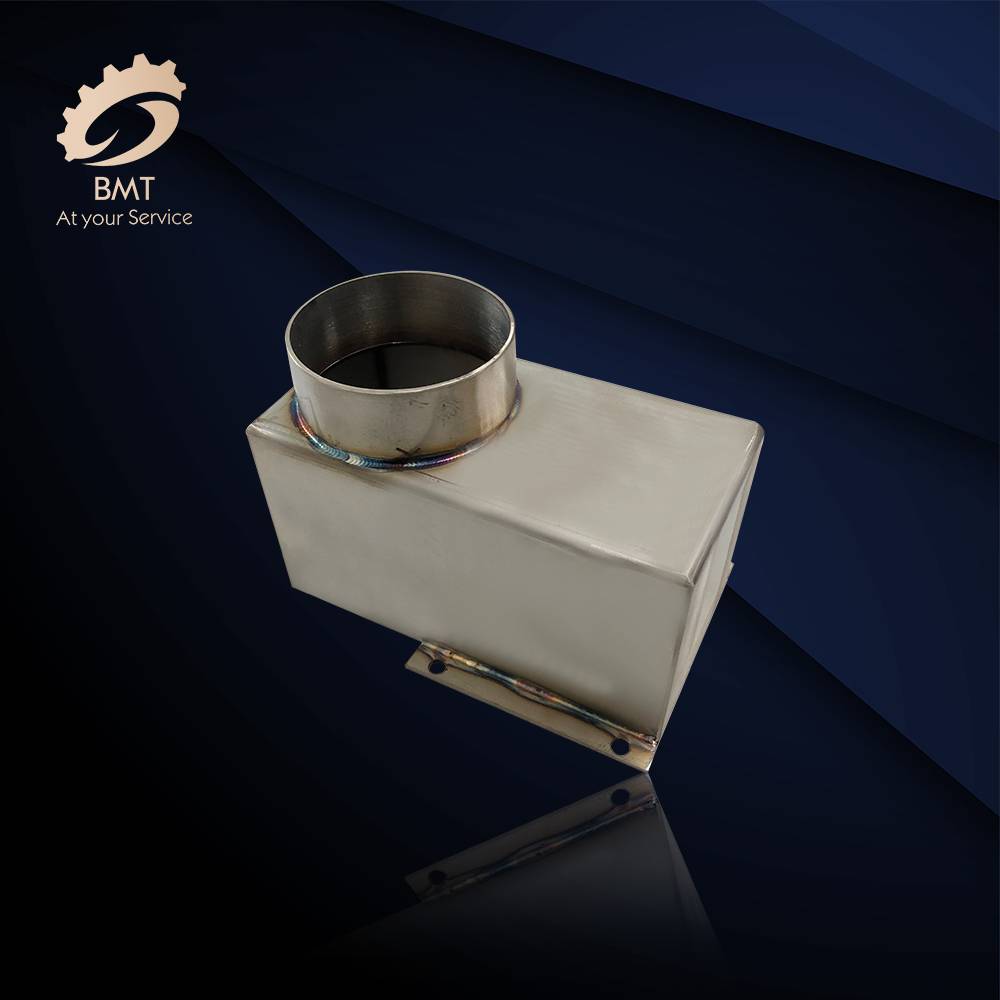

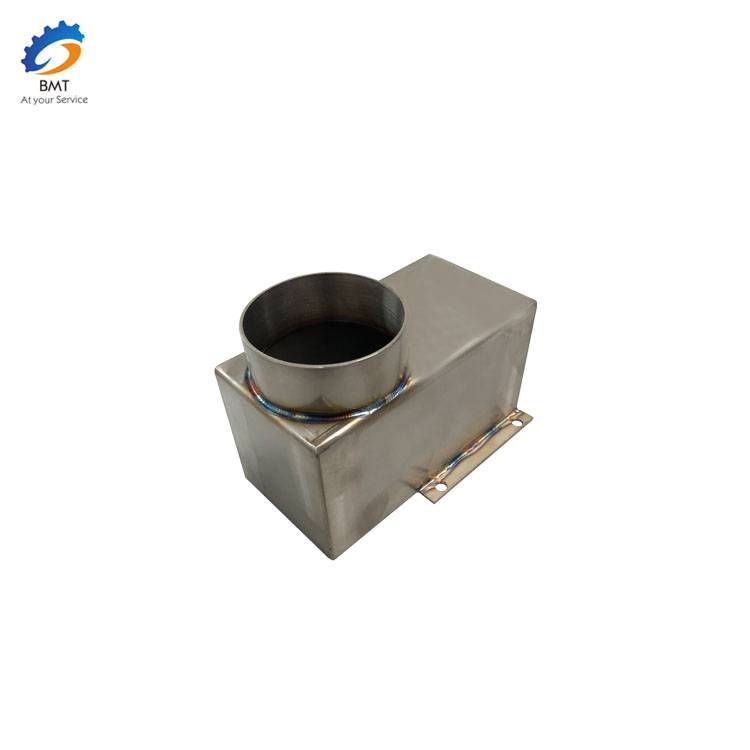

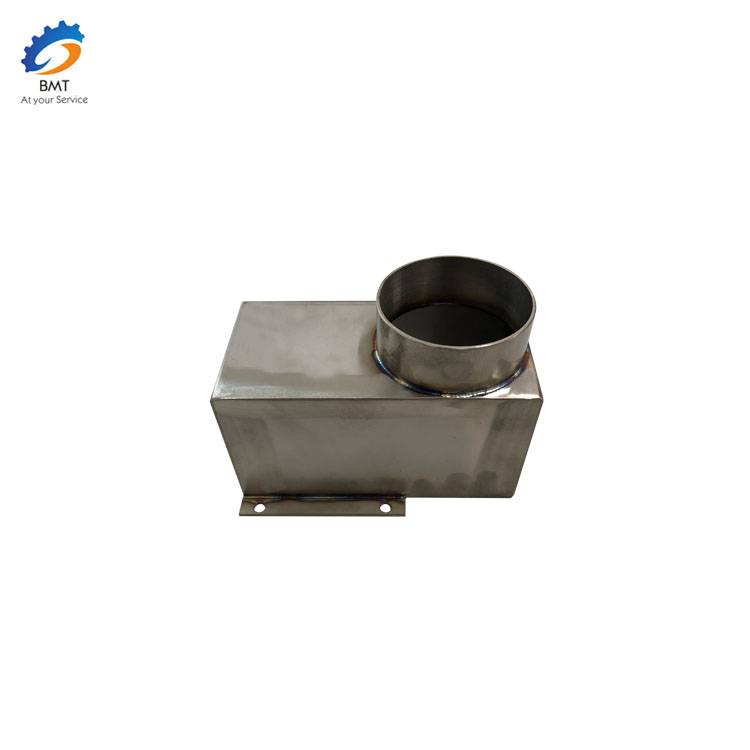

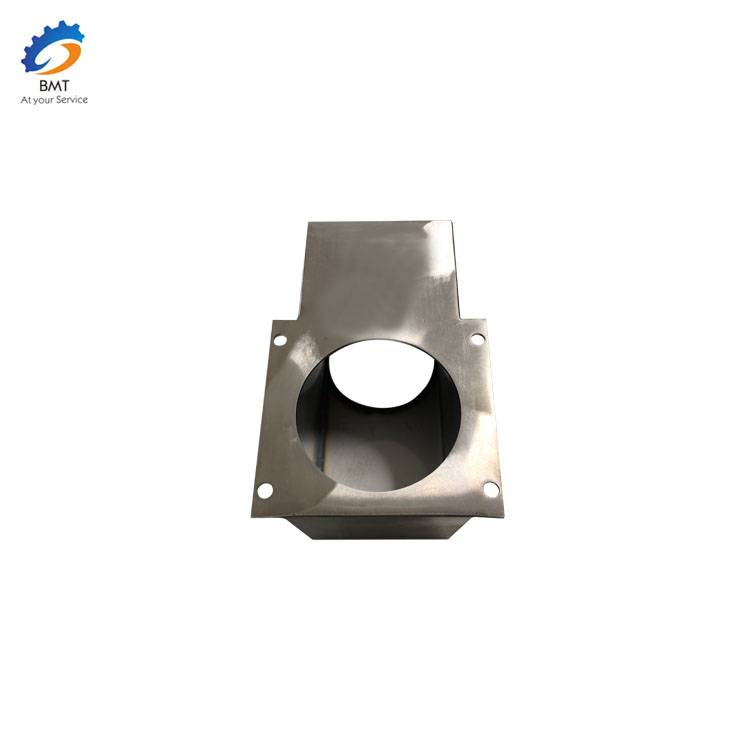

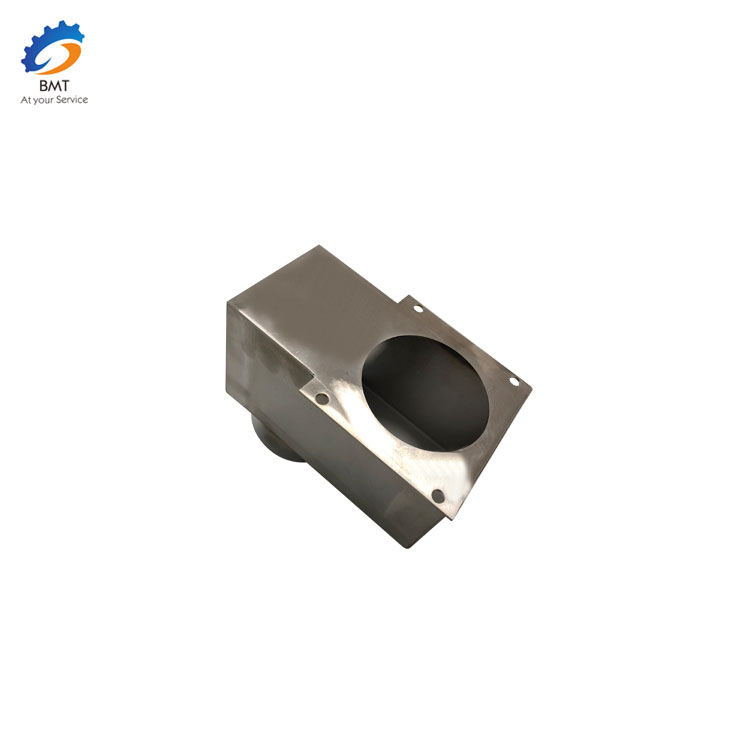

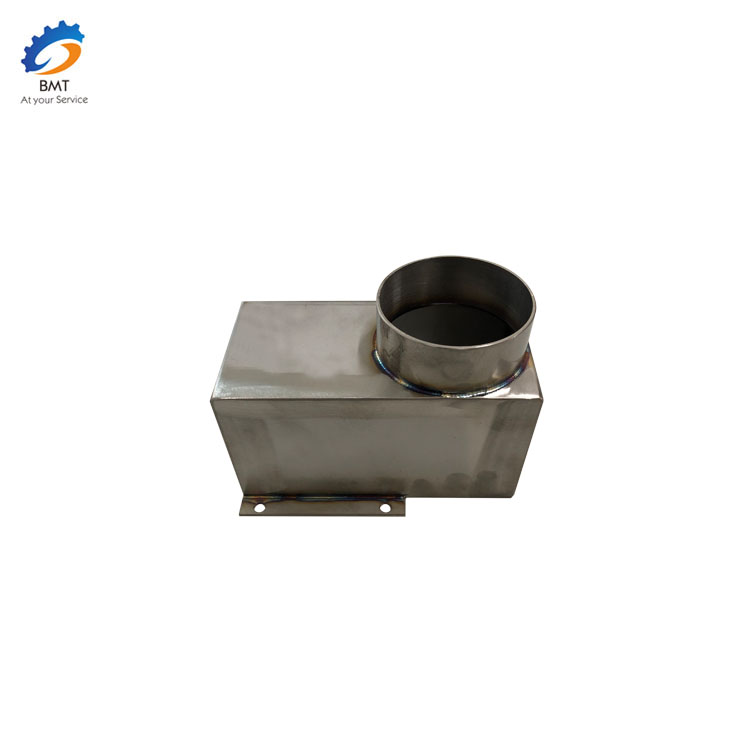

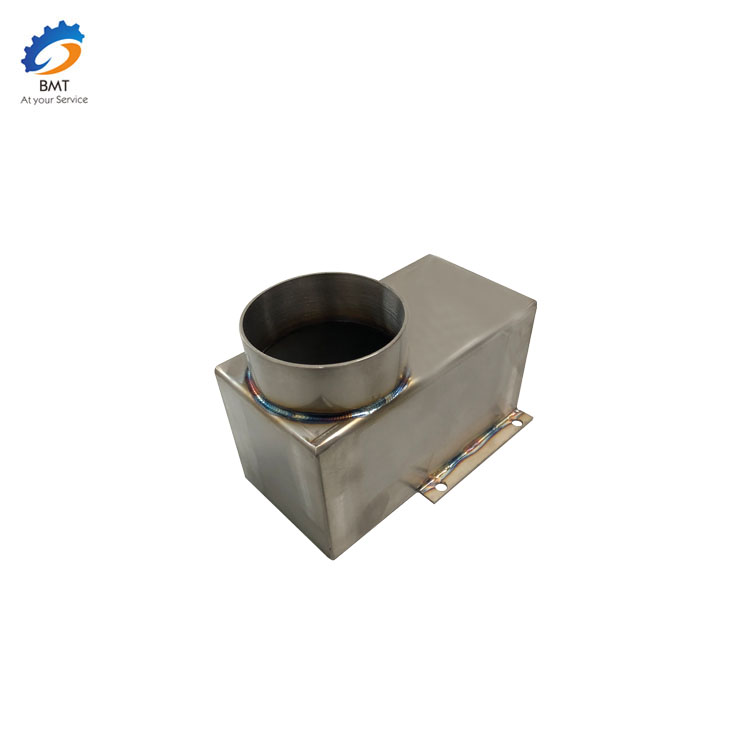

Incazelo Yomkhiqizo

Konke odinga ukukwazi ngensimbi yensimbi engagqwali kulapha. Insimbi yensimbi engagqwali ingenye yezinto zokwakha ezitholakala emhlabeni wonke. Akukhona nje kuphela ukuthi iqinile futhi iyathengeka, futhi kulula ukusebenza nayo. Ingasetshenziswa kumaphrojekthi asukela ezimbonini ezinkulu kuye kweziyinkimbinkimbi zikagesi, futhi cishe yonke into ephakathi.

Nakhu konke odinga ukukwazi mayelana nokusebenza ngensimbi engagqwali ezinhlelweni ezidinga ukwenziwa kweshidi lensimbi:

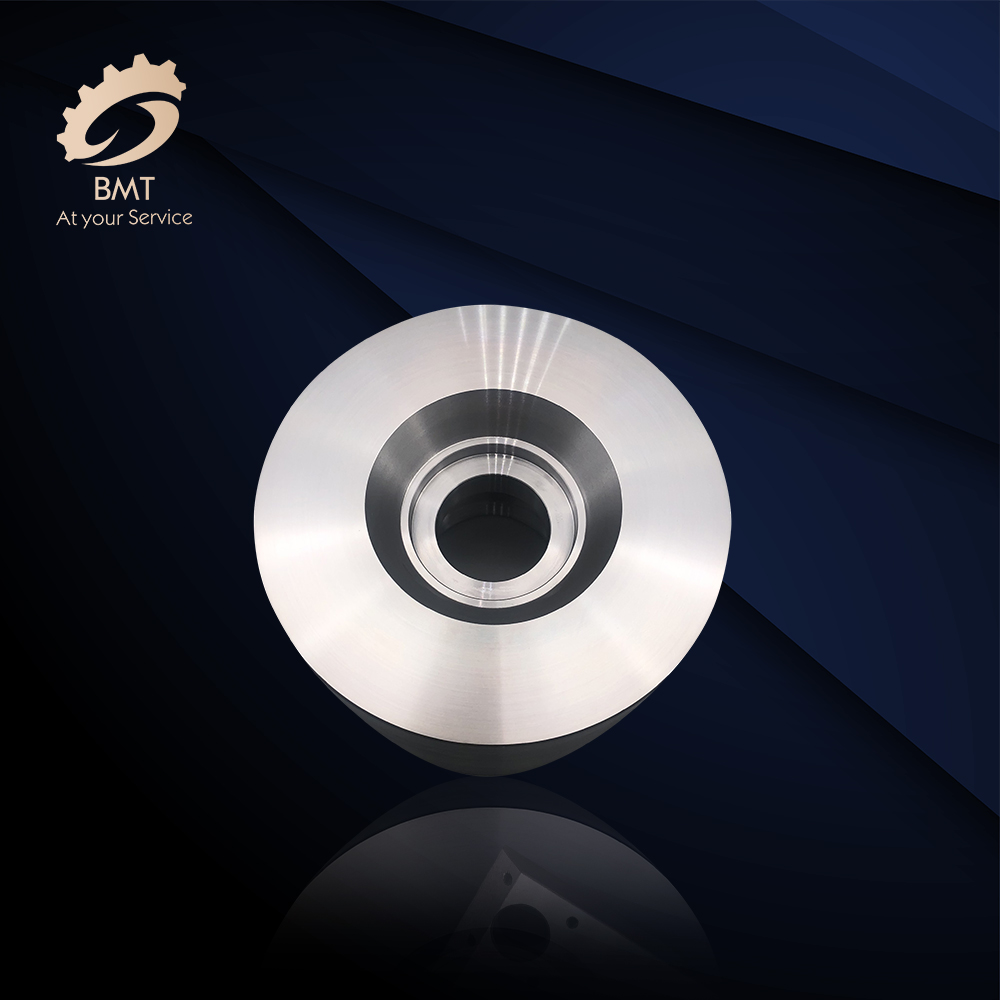

Izakhiwo ze-Stainless Steel Sheet Metal

Insimbi engagqwali ingxubevange yensimbi equkethe okungenani u-10.5% Cr. Okuqukethwe kwe-Cr yikho okunikeza insimbi izinto zayo zokunqanda ukugqwala kanye ne-anti-staining. Okuqukethwe kwe-Cr kwangempela, kanye nokuqukethwe kwe-C nokuqukethwe kwezinye izinsimbi, kuyahlukahluka ngokuya ngesicelo lapho insimbi izosetshenziswa khona.

Kumele kuqashelwe ukuthi insimbi engagqwali ayikona ngokuphelele ukugqwala noma ubufakazi bebala. Ukumelana nensimbi kuzoncika kokuqukethwe kwayo, futhi amakhemikhali athile angalimaza insimbi kungakhathaliseki ukuthi iquketheni. Kodwa-ke, i-stainless inikeza ukugqwala okungcono kakhulu nokumelana namabala okutholakalayo, ikakhulukazi uma ucabangela ezinye izimfanelo ezinikezayo, njengokuqina.

Insimbi yensimbi engagqwali ingaba mncane impela, kodwa ifaneleke “njengensimbi yeshidi”, ifinyelela kuphela intshi engu-¼ ubukhulu, okubizwa ngokuthi “ipuleti.” Ubukhulu kanye neshidi lensimbi engagqwali kufanele likalwe ngegeji. Lapho inombolo yegeji iphakeme, ishidi liyancipha.

Insimbi yensimbi engagqwali iza ngezindlela ezihlukahlukene, ngayinye inezinzuzo kanye nokubi. Abakhiqizi bangase banikeze amabanga ahlukene, ukuphathwa kwendawo kanye nobukhulu, kodwa lezi zinhlobo ziyindinganiso yabakhiqizi. Lezi zinhlobo zihlanganisa:

● 200 Series Austenitic

● 300 Series Austenitic

● I-Martensitic

● I-Ferritic

● I-Duplex

Ukusebenza ngeshidi lensimbi yensimbi kulula, nakuba kunezinselele kuye ngokuthi uzama ukwenzani kanye nebanga olisebenzisayo. Isibonelo, amashidi amancane adinga ukunakekelwa lapho eshiswa ukuze agweme ukugoqa noma ukuvutha, kuyilapho amashidi aminyene angaba nzima ukugoba.

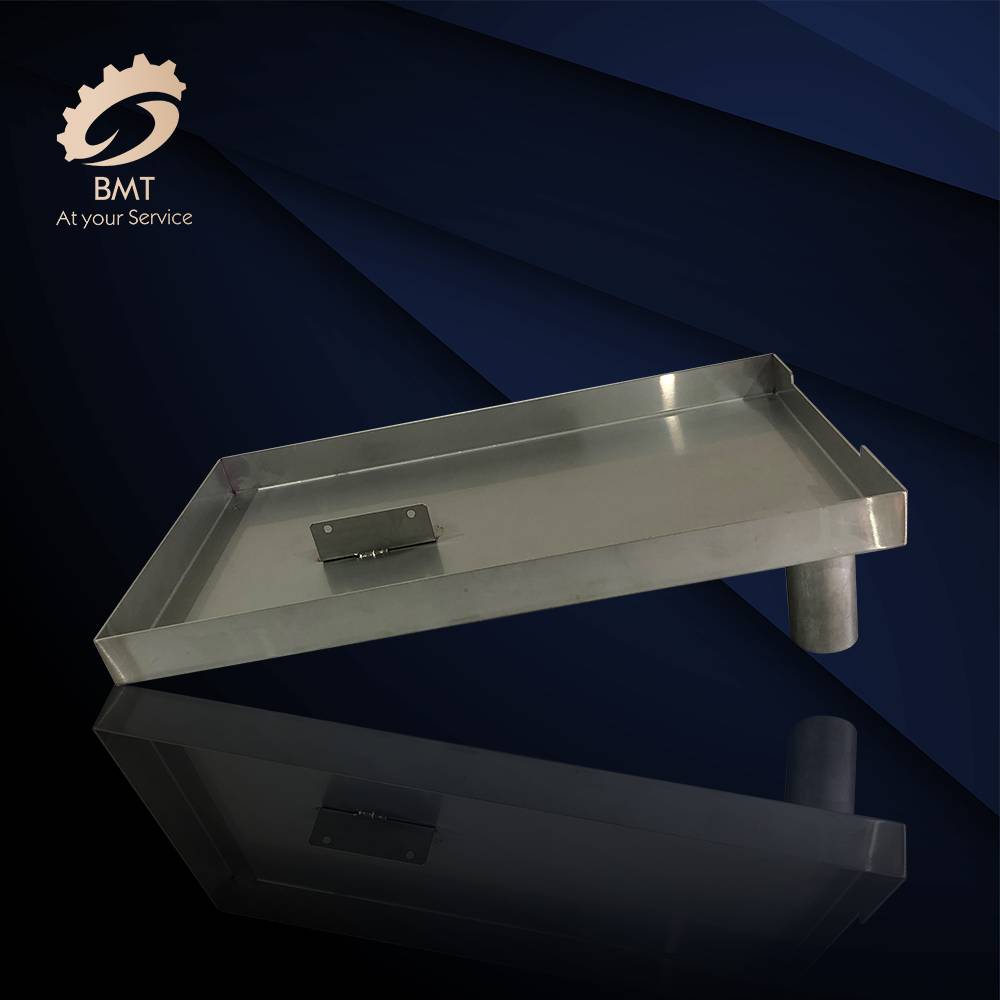

Ukushisela, Ukugoba kanye Nokusika izindlela ezintathu eziyinhloko zokusebenza kwensimbi yensimbi engagqwali. Kodwa-ke, ubunzima obukhulu bokushisela insimbi yensimbi engagqwali ukushuba kwensimbi nokusabalalisa ukushisa. Njenganoma yiliphi ishidi lensimbi elincanyana, ukushisa okukhulu kakhulu okusebenza ngokushesha kuzolimaza insimbi, futhi kunengozi yokusha. Ukushisela kwe-MIG kusinikeza ukulawula okuhle kokushisa, kodwa umenzi usazodinga ukuhlanganisa i-weld ngendlela efanele futhi asebenzise amatheki amaningi ukuze ayigcine isendaweni. Onjiniyela kufanele basabalalise ukushisa futhi bavumele insimbi ukuthi iphole ASAP.

Lapho ishidi liba mncane, kuba lula ukugoba. Amashidi azacile angagotshwa ngesandla, kuyilapho amashidi aminyene azodinga ithuluzi lokugoba, njengomshini wokugoba we-CNC. Ukusebenza ngekhodi yomshini nokuhlela, umshini ungabona kahle kakhulu ngokugoba okudingekayo.

Amashidi angasikwa kusetshenziswa umshini wokusika we-laser wobuchwepheshe obuphezulu noma umshini wokusika we-plasma nanoma yiziphi ezinye izinhlobo zemishini.

Izingxenye zensimbi Zeshidi Lensimbi Engagqwali ziyahlukahluka ngezindlela ezahlukene kusukela ekhishini lethu kuye edolobheni elinezindlela eziningi ezisetshenziswayo, njengoba linogqinsi nezinhlobo eziningi. Ngokuvamile, ingasetshenziswa ku:

● Izakhiwo

● Ukwakha

●Ezezimoto

●Ezokwelapha

●Inkonzo yokudla

●Imboni enzima

●Amandla

Ngezakhiwo zeshidi lensimbi engagqwali elisebenzisekayo, elenziwa ngokwezifiso futhi elihle kakhulu lisebenza ezinhlelweni eziningi. Uma ungaqiniseki ngalokho okwenzayo ngensimbi engagqwali noma i-aluminium, sibuze, umakhi wensimbi ochwepheshile. Umakhi wensimbi onolwazi angakutshela ukuthi iphrojekthi yakho idinga ngempela yini noma uma ungakwazi ukubalekela enye into.