Izindlela Ezi-5 Zokuthuthukisa Izingxenye Zensimbi Zeshidi

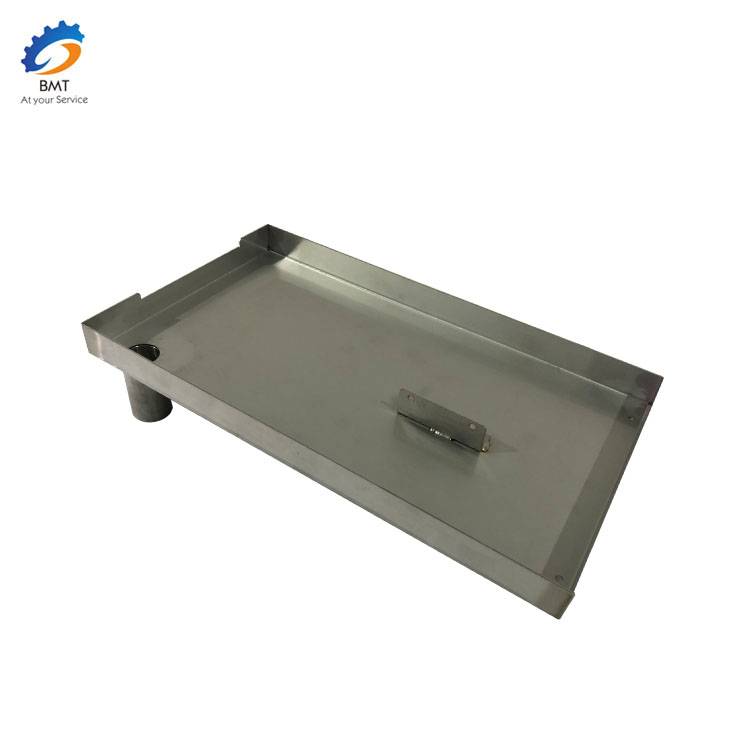

Ukwenziwa kwensimbi yeshidi isethi ewusizo yezinqubo zokukhiqiza ezisetshenziselwa ukwakha izingxenye ngezingcezu zensimbi eziyisicaba. Ishidi lensimbi liza ngohlu lwezinto ezisetshenziswayo nogqinsi, futhi lingasetshenziswa ukwakha izingxenye ezifana nezinto zikagesi, izivalo, abakaki, amaphaneli kanye ne-chassis, njll.

Uma kuqhathaniswa nemishini ye-CNC, ukwakhiwa kweshidi lensimbi kunqunywa ukucaciswa kwedizayini okuqinile kakhulu. Kwabanye abasebenzi abasha ekwenzeni amashidi ensimbi, mhlawumbe kunzima. Insimbi yeshidi kufanele igotshwe futhi isikwe ngezindlela ezithile, futhi ifanele izingxenye ezithile kanye nemikhiqizo ethile kuphela.

Eqinisweni, kubalulekile ukufunda izimiso ezithile eziyisisekelo zokwenziwa kweshidi lensimbi ngaphambi kokusebenza. Besebenzisa ukwakhiwa kweshidi lensimbi, ochwepheshe bangakha izingxenye eziqinile, ezingabizi kakhulu ezivela ezintweni ezihlukahlukene. Lezi zingxenye zingasetshenziswa kuzo zonke izimboni eziningi, kusukela ku-aerospace kuya ezintweni zikagesi zasekhaya.

Ugqinsi lweshidi lensimbi olusetshenziswa enqubweni yokukhiqiza ngokuvamile luphakathi kuka-0.006 no-0.25”, ubukhulu buncike ezintweni ezinikeziwe nasekusetshenzisweni kokuphela kwengxenye.

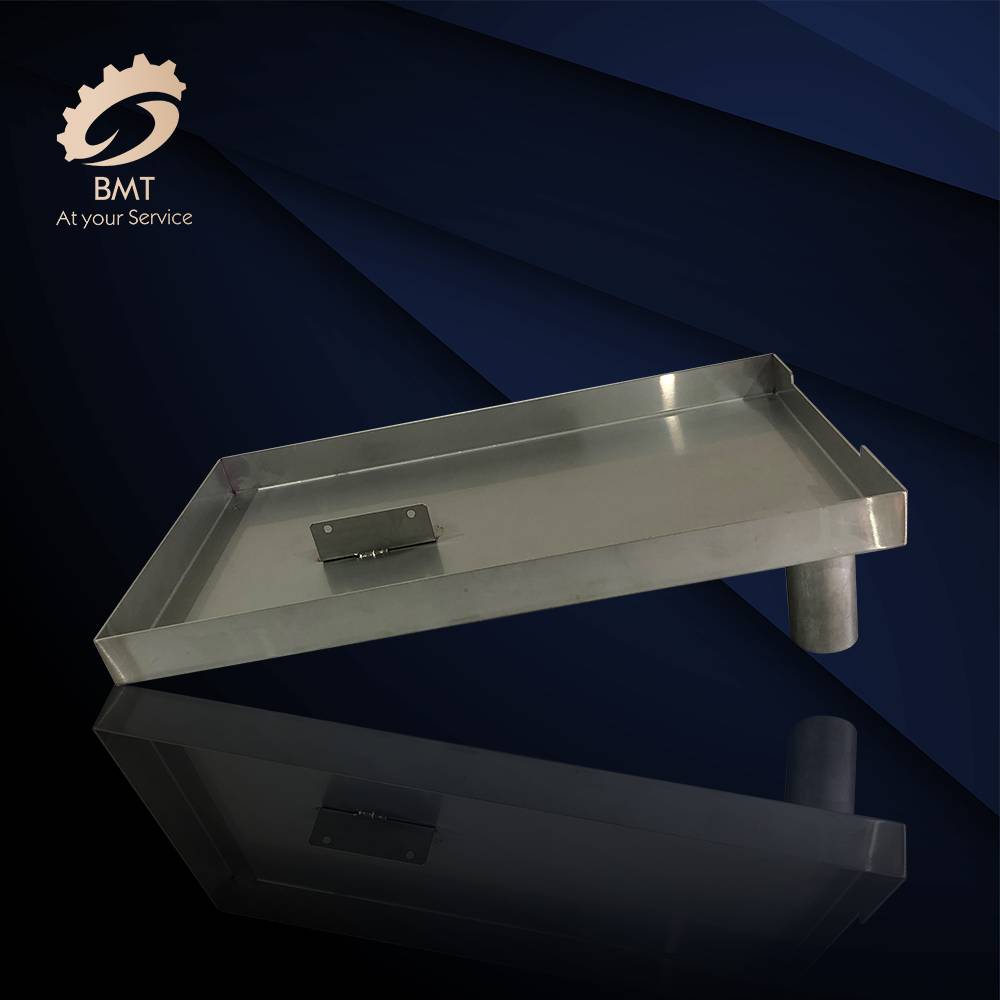

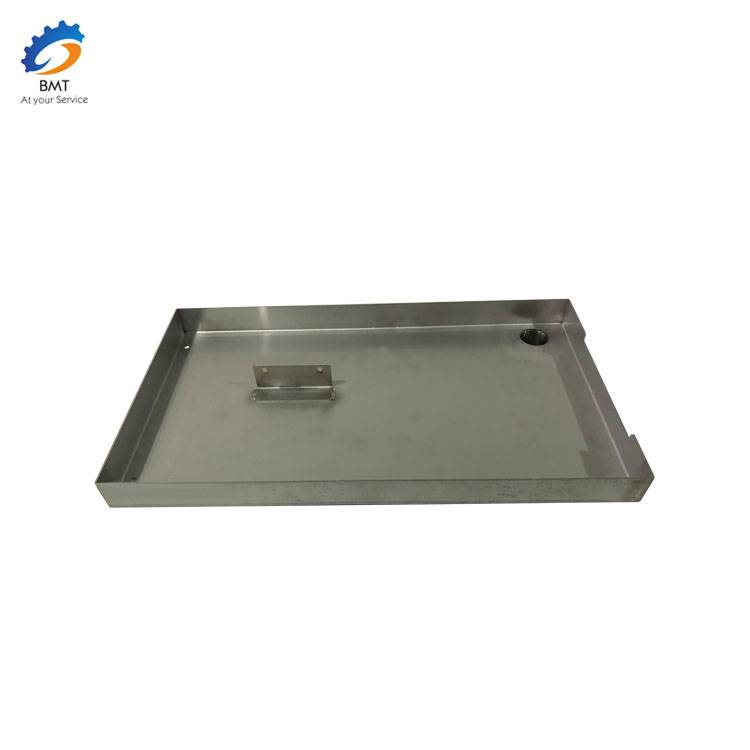

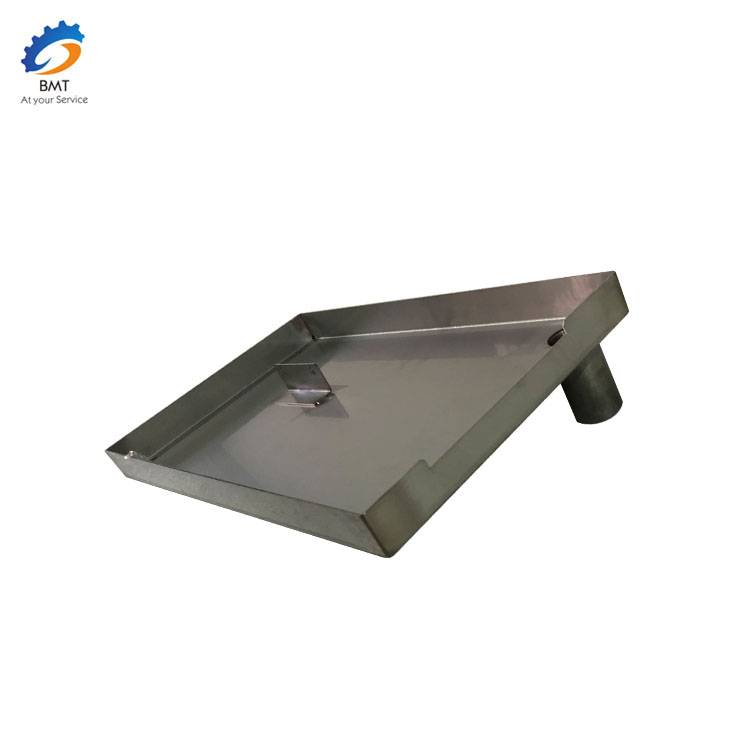

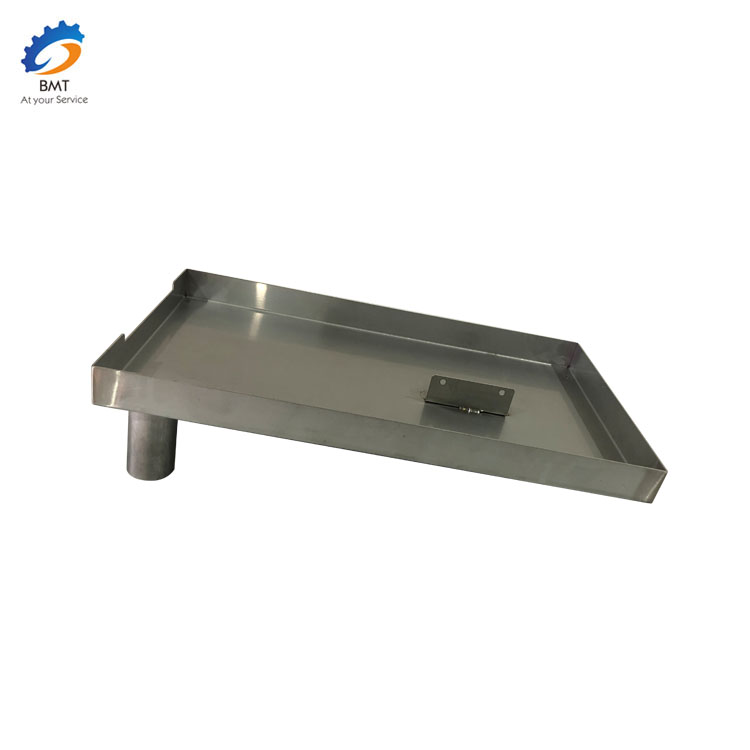

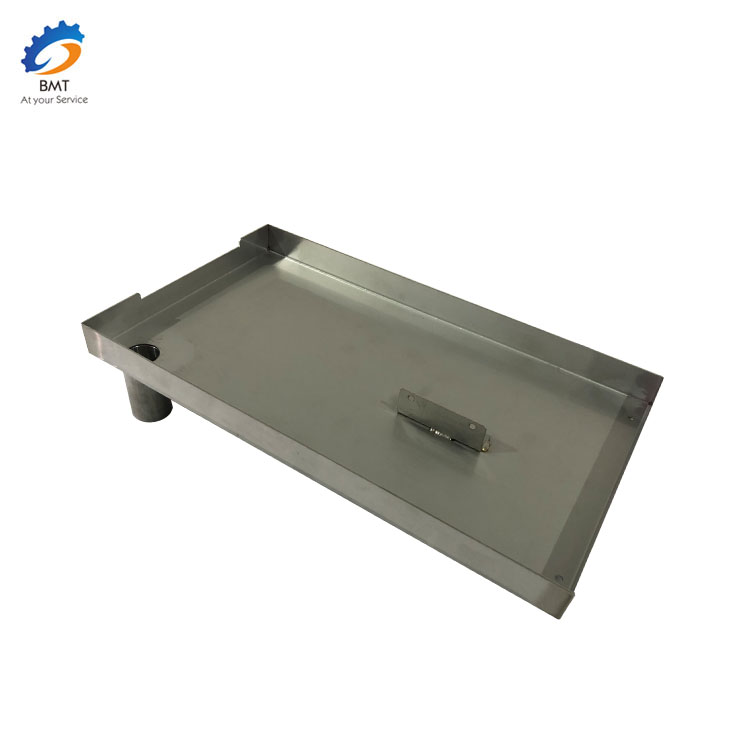

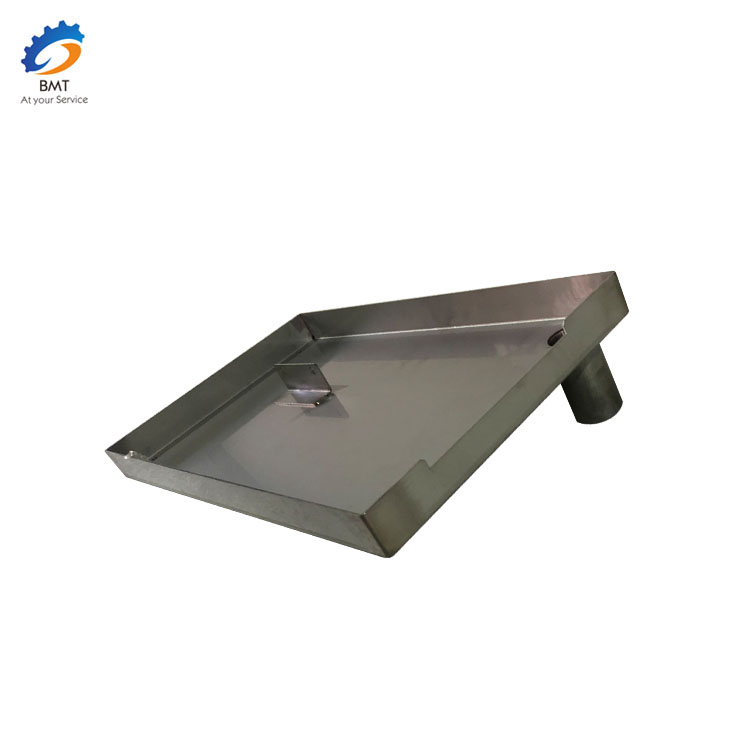

Incazelo Yomkhiqizo

Ukwenziwa kwensimbi yamashidi kuyingqayizivele phakathi kwezinqubo ezihlukahlukene zokukhiqiza. Ngalesi sizathu, ochwepheshe mhlawumbe bangaklama izingxenye zemishini ye-CNC noma izingxenye zesikhunta, kodwa kunzima ukuklama izingxenye zensimbi zeshidi.

Ngokubheka amathiphu ayisithupha alandelayo, abaklami bangakha izingxenye zensimbi eziqinile, ezilula ukuzenza futhi ezimelana kakhulu nokuphuka.

1. Izimbobo kanye Slots

Njengoba ukwakhiwa kwensimbi yeshidi kuvame ukusetshenziselwa ukwakha izivalo, abakaki nezinto ezifanayo, izimbobo nezikhala zivame ukudingeka ukuze kufakwe izikulufo, amabhawodi noma izigaba ezihlanganisiwe. Izimbobo zivame ukwakhiwa nge-punch bese zifa zifakwe emshinini wokunyathelisa, okuvumela ukuthi umumo oqondile oyindilinga unqunywe ensimbi yeshidi. Kodwa uma izimbobo zingenziwanga kahle, imbobo ingase ikhubazeke noma ibangele ukuba ingxenye ngokwayo iphuke.

Lapho ubhoboza izimbobo eshidini lensimbi, imithetho embalwa ebalulekile kufanele ilandelwe. Izimbobo kufanele zibe ngu-1/8” kunoma yiluphi udonga noma unqenqema futhi kufanele zihlukaniswe okungenani izikhathi eziyisi-6 kunogqinsi lweshidi lensimbi. Ngaphezu kwalokho, ama-diameter azo zonke izimbobo nezikhala kufanele afane noma adlule ubukhulu beshidi lensimbi.

2. Imiphetho

I-Hemming iyindlela enhle yokwenza ingxenye yensimbi yeshidi iphephe futhi isebenze. Sakha imiphetho evulekile nevaliwe. Ukubekezelelwa komphetho kuncike ebubanzini bomphetho, ukujiya kwempahla, nezici eduze komphetho. Sincoma ukuthi ubuncane be-diameter yangaphakathi bulingane nogqinsi lwempahla, kanye nobude bokubuya komphetho obungu-6x wezinto ezibonakalayo.

Lapho wengeza umphetho engxenyeni yensimbi yeshidi, imihlahlandlela embalwa kufanele ilandelwe ukuze kuqinisekiswe ukusebenza kahle. Okokuqala, cishe njalo kungcono ukugwema imiphetho evaliwe. Amahemu avaliwe engcupheni yokulimaza impahla ngenxa ye-engeli eyeqisayo yokugoba, ngakho-ke ama-hem avulekile, ashiya igebe phakathi kwezinhlangothi ezimbili zomphetho, ayakhethwa.

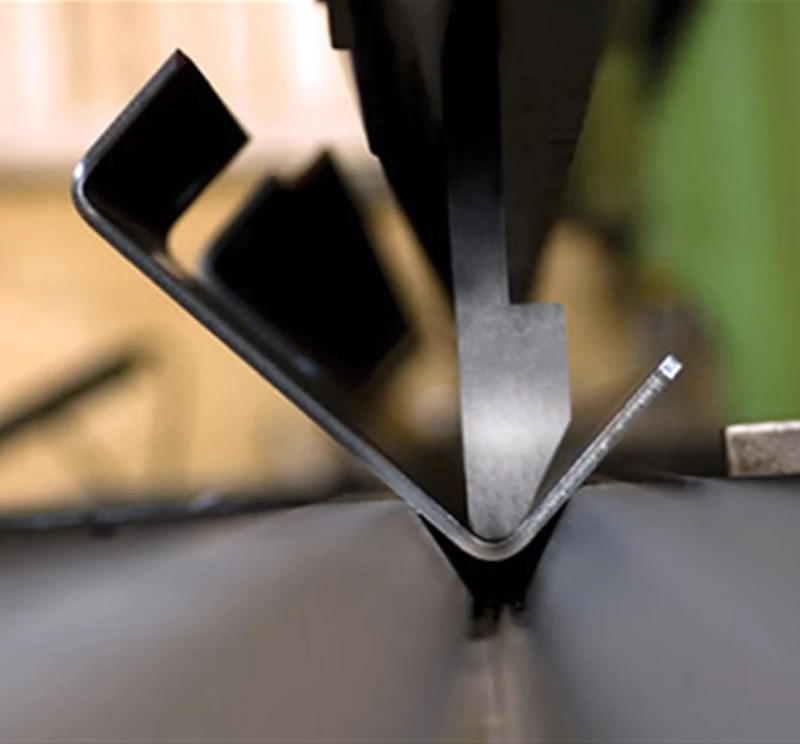

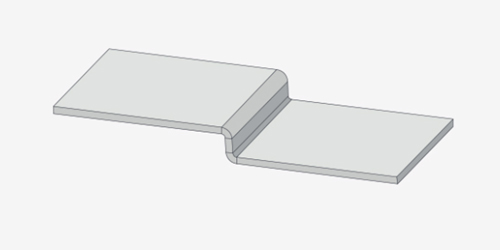

3. Amagoba

Ukugoba kungenye yezinqubo ezibaluleke kakhulu zokwakha ekwakhiweni kwensimbi yeshidi. Isebenzisa amathuluzi afana namabhuleki nomshini wokunyathelisa, ifektri iyakwazi ukwenza insimbi ibe yizimo ezintsha. Ukugoba, ukuze kuqinisekiswe ukugoba okunembile ngisho nokugoba, kufanele silandele imithetho ethile, futhi sinciphise amathuba okulimala kwento.

Umthetho owodwa okufanele ulandelwe ukuthi, lapho uklama ingxenye yeshidi yensimbi enamagobe, i-radius egobile yangaphakathi kufanele ifane noma yeqe ukujiya kweshidi lensimbi ukuze kugwenywe ukuwohloka. Kunconywa ukuthi usebenzise irediyasi efanayo kuwo wonke ama-bends. Ukugcina ukungaguquguquki ekuqondeni kokugoba kanye nerediyasi kungasiza ekwehliseni izindleko, njengoba ingxenye ngeke kudingeke ukuthi iqondiswe kabusha futhi okokusebenza kokugoba kungaphinda inqubo eyodwa efanayo.

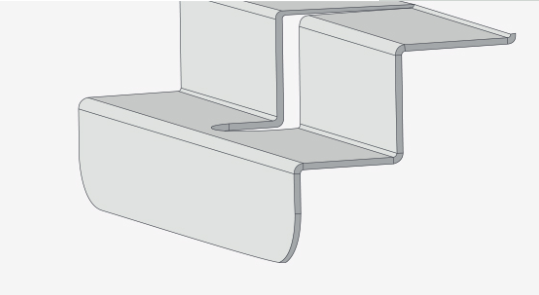

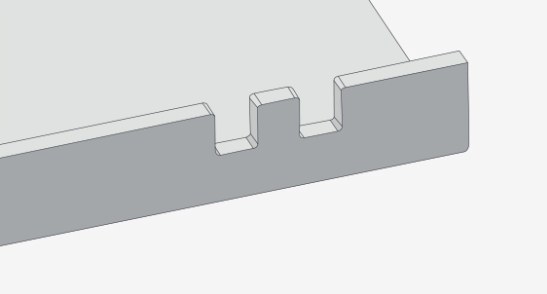

4. Inothi namathebhu

Amanotshi namathebhu yizici eziyinhloko zezingxenye zensimbi zeshidi eziwusizo ekungezeni izikulufu noma izixhumi noma ukuxhuma izingxenye eziningi ndawonye. Ama-notches ama-indenti amancane emaphethelweni engxenye, kuyilapho amathebhu ayizici ezivelele. Ithebhu engxenyeni yensimbi yeshidi ivamise ukuhlanganiswa ukuze ingene kunotshi yenye ingxenye.

Njengezinye izici zensimbi yeshidi, ukwakha izinotshi namathebhu afanelekile nakho kudinga ukulandela imithetho ethile: izinotshi kufanele okungenani zibe ukujiya kwempahla noma u-1mm, kuye ngokuthi yikuphi okukhulu, futhi angeke kube ngaphezu kuka-5 ububanzi bayo. Amathebhu kufanele abe okungenani izikhathi ezi-2 ubukhulu bomsebenzi noma u-3.2mm, kuye ngokuthi yikuphi okukhulu, futhi angeke abe ngaphezu kokuphindwe ka-5 ububanzi bawo.

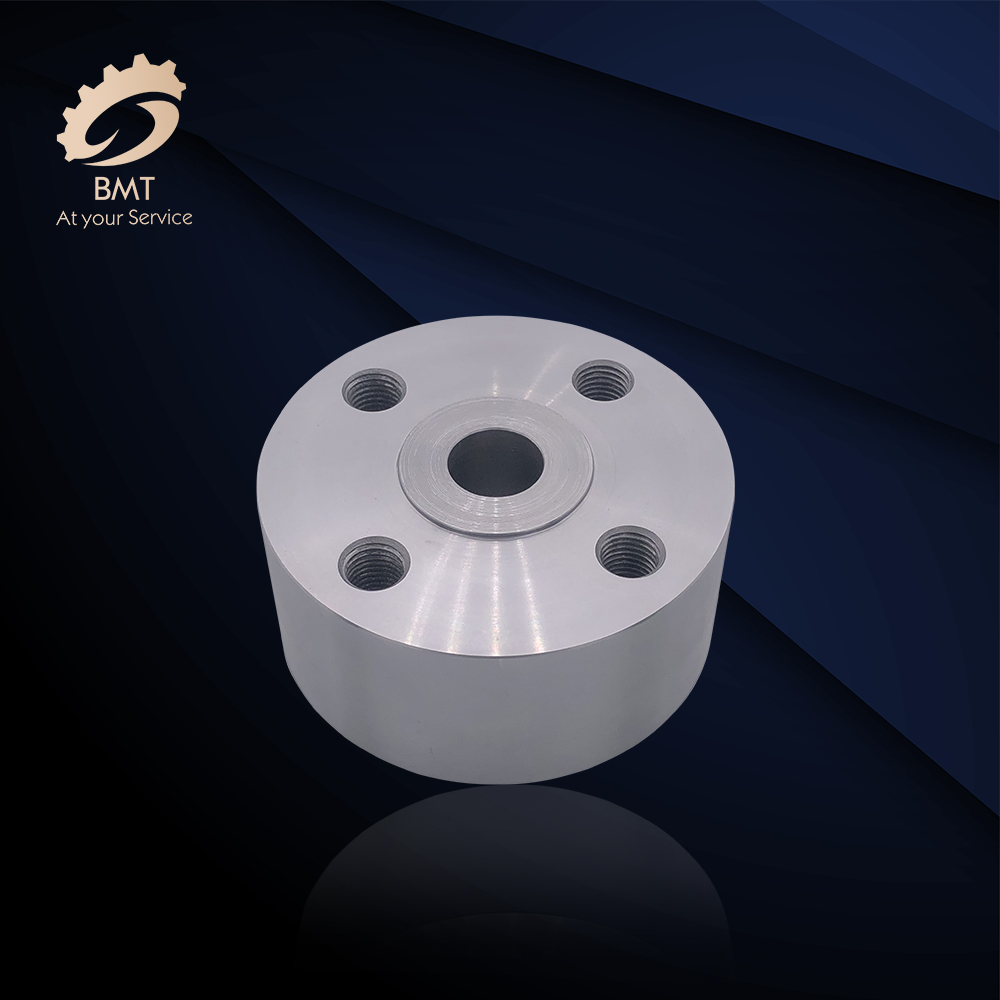

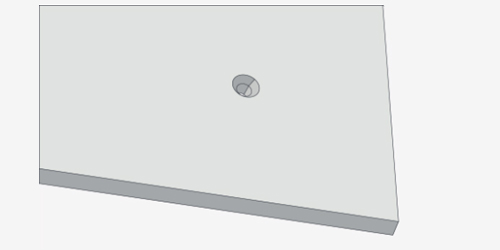

5. Ama-Offset nama-Countersink

Ama-Countersink angenziwa yi-CNC Machining noma akhiwe ngemishini ekhethekile. Ukubekezelela usayizi omkhulu we-countersink owenziwe kuqinile kakhulu, ngoba mhlawumbe udinga ukusetshenziswa nezikulufu noma izixhumi. Ama-offset asetshenziselwa ukudala amaphrofayili amise okwe-Z ezingxenyeni zensimbi zeshidi.

6. Ukuqeda

Kuye ngokusetshenziswa kanye nezinto ezisetshenzisiwe, izingxenye zensimbi zeshidi zingaqedwa ngokuqhunyiswa kobuhlalu, i-anodizing, i-plating, i-powder coating nezinye izinqubo ezihlukahlukene, kungaba ngezinhloso zokusebenza noma ukuthuthukisa ukubukeka kwengxenye.