I-Pulse kanye ne-Continuous Wave Modes

Ingxenye ebalulekile ye-micromachining optical ukudluliselwa kokushisa endaweni ye-substrate eseduze ne-micro-machined material. Ama-Lasers angasebenza kumodi ye-pulsed noma imodi yegagasi eqhubekayo. Kumodi yegagasi eqhubekayo, ukuphuma kwe-laser kuhlala njalo ngokuhamba kwesikhathi.

Kumodi ye-pulsed, ukuphuma kwe-laser kugxilwe kuma-pulses amancane. Imishini ye-laser yemodi eshayekile ihlinzeka ngama-pulses nobude be-pulse encane ngamandla anele e-micromachining yento enikeziwe. Ubude be-pulse encane bunciphisa ukugeleza kokushisa ezintweni ezizungezile. Ama-Laser pulses angahluka ngobude ukusuka kuma-milliseconds kuye kuma-femtoseconds.

Amandla aphezulu ahlobene nobude be-laser pulse, ngakho-ke ama-laser ashayayo angafinyelela iziqongo eziphakeme kakhulu kunamagagasi aqhubekayo.

Ukucutshungulwa kwe-laser ngokuyinhloko kubandakanya ukusebenzisana okuholela ekukhishweni kwe-substrate material. Ukudluliswa kwamandla okwenzekayo kuncike ezintweni ezibonakalayo kanye nezakhiwo ze-laser. Izici ze-laser ezinomthelela zifaka amandla aphezulu, ububanzi be-pulse, kanye ne-wavelength ephumayo. Ukucatshangelwa kwezinto ezibonakalayo ukuthi ingakwazi yini ukumunca amandla e-laser ngezinqubo ezishisayo kanye/noma ze-photochemical.

Kungani ububanzi be-pulse bubalulekile?

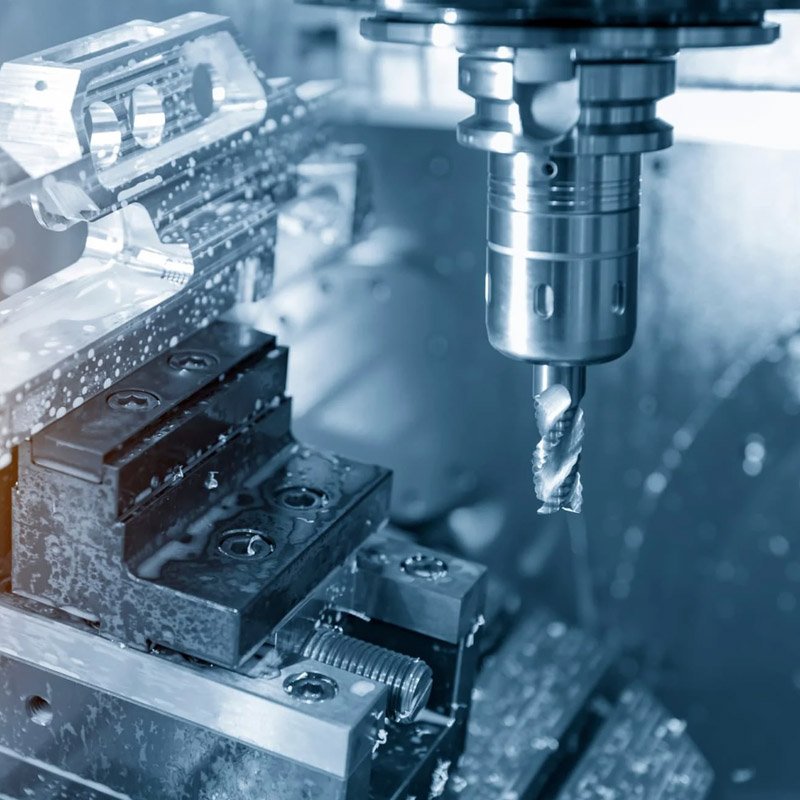

Ukusika i-laser kuhlanzekile futhi kunembile. Isidingo sokwenza amadivaysi amancane, asheshayo, alula futhi anezindleko eziphansi sidinga ama-laser ukuhlangabezana nenselele. Ama-laser pulsed asetshenziselwa ukunemba kwe-micromachining yezinto ezahlukahlukene. Ikhono lokukhiqiza ububanzi be-pulse obuhlukene buyisihluthulelo sokunemba, ukuphuma, ikhwalithi kanye nokusebenza kahle kwezindleko.

Amalaser e-Nanosecond asebenzisa amandla amaphakathi afanayo anamazinga aphezulu okususwa kwezinto futhi ngenxa yalokho amandla okusebenza aphezulu kune-picosecond ne-femtosecond lasers.

I-Picosecond kanye ne-femtosecond lasers iyancibilika ukuze isuswe ngenqubo yokuhwamuka nokuncibilikisa okokusebenza ukuze kukhishwe. Lokhu kuncibilika kungathinta ukunemba kanye nekhwalithi yomshini, njengoba izinto ezisusiwe zinganamathela emaphethelweni futhi ziqinise.

Intuthuko kubuchwepheshe be-laser pulsed yenze kwaba nokwenzeka ukusebenzisa i-micromachining kumadivayisi amancane, njengamathuluzi ezokwelapha, anomonakalo omncane ezintweni ezizungezile. Ngokuthuthuka okusheshayo kwesayensi emkhakheni wama-lasers, ubuchwepheshe be-laser micromachining bubalulekile.

Inqubo yokukhiqiza yomshini isho yonke inqubo yokwenza umkhiqizo ngezinto ezingavuthiwe (noma imikhiqizo eqedwe kancane). Ngokukhiqizwa komshini, kuhlanganisa ukuthuthwa nokugcinwa kwezinto zokusetshenziswa, ukulungiswa kokukhiqiza, ukukhiqiza okungenalutho, ukucubungula izingxenye kanye nokwelashwa kokushisa, ukuhlanganiswa komkhiqizo, nokulungisa iphutha, ukudweba nokupakisha, njll. Okuqukethwe kwenqubo yokukhiqiza kubanzi kakhulu. Amabhizinisi esimanje asebenzisa izimiso nezindlela zobunjiniyela bezinhlelo ukuhlela nokuqondisa ukukhiqizwa, futhi abheke inqubo yokukhiqiza njengohlelo lokukhiqiza olunokufakwayo nokuphumayo.

Isikhathi sokuthumela: Oct-13-2022