I-Precision machining iyinqubo ebucayi embonini yokukhiqiza, futhi ukusetshenziswa kwezinto ezihlukahlukene kwengeza inkimbinkimbi nokwehluka ekukhiqizeni ukunemba.izingxenye zomshini. Kusukela ezinsimbi kuya kumapulasitiki, ububanzi bezinto ezisetshenziswa ekwenzeni imishini enembile bukhulu, futhi impahla ngayinye iveza isethi yayo yezinselelo namathuba kubakhiqizi. Izinsimbi zivame ukusetshenziswa emishinini enembayo ngenxa yamandla azo, ukuqina, nokumelana nokushisa. Insimbi engagqwali, i-aluminiyamu, i-titanium, nethusi kuyizibonelo ezimbalwa nje zezinsimbi ezivame umshini ukuze kudaleke izingxenye ezinembayo. Insimbi ngayinye idinga amasu omshini namathuluzi athile ukuze kuzuzwe ukunemba nokuqeda okufunayo. Isibonelo, insimbi engagqwali yaziwa ngobulukhuni nokuqina kwayo, idinga amathuluzi okusika akhethekile namasistimu okupholisa ukuvikela ukushisa ngokweqile nokugcina ukunemba ngesikhathi somshini.

Ngaphezu kweizinsimbi, ipulasitikinazo zisetshenziswa kabanzi ekwenzeni ukunemba. Izinto ezifana nenayiloni, i-polycarbonate, ne-acrylic zinikeza izakhiwo eziyingqayizivele njengokuguquguquka, ukucaca, nokumelana namakhemikhali, okuzenza zifanelekele uhla olubanzi lwezinhlelo zokusebenza. Ukwenza amapulasitiki ngomshini kudinga ukucatshangelwa ngokucophelela kwezinto ezifana nokukhiqiza ukushisa, ukukhetha amathuluzi, nokulawulwa kwe-chip ukuze kugwenywe ukuncibilika noma ukusonteka kwezinto. Ngaphezu kwalokho, ukusetshenziswa kwezinto eziyinhlanganisela emishinini enembayo sekuthole ukuduma eminyakeni yamuva nje. Izinhlanganisela, ezenziwe ngokuhlanganisa izinto ezimbili noma ngaphezulu ukuze kwakhiwe into entsha enezakhiwo ezithuthukisiwe, zinikeza enye indlela engasindi futhi enamandla aphezulu kunezinsimbi zendabuko. I-Carbon fibre, i-fiberglass, ne-Kevlar yizibonelo zezinhlanganisela ezenzelwa ukukhiqiza izingxenye ezinembayo zezimboni ezifana ne-aerospace, ezezimoto, nemishini yezemidlalo.

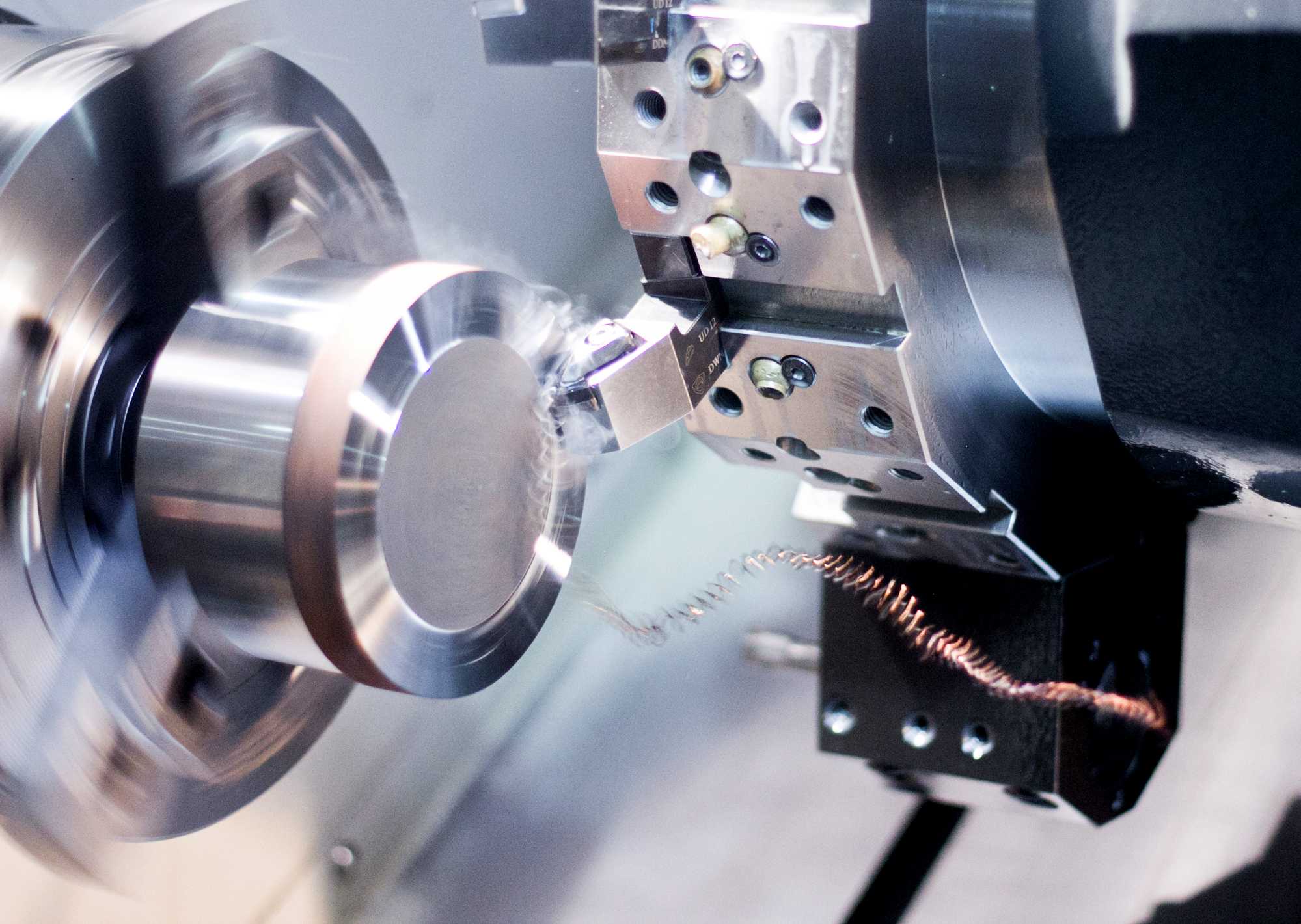

Ukukhethwa kwempahla efaneleukunemba imishinikuncike ezidingweni ezithile zengxenye, okuhlanganisa izakhiwo zemishini, ukunemba kobukhulu, kanye nokuqedwa kwendawo. Abakhiqizi kufanele bahlole ngokucophelela izici zento ngayinye futhi balungise izinqubo zabo zokwenza imishini ukuze bathole umphumela abawufunayo. Ngokungeziwe ekukhethweni kwezinto ezibonakalayo, ukunemba kwemishini kuhlanganisa nokusetshenziswa kobuchwepheshe obuthuthukisiwe obunjengokwenza imishini yokulawula izinombolo zekhompyutha (i-CNC), i-multi-axis milling, kanye ne-electrical discharge machining (EDM). Lobu buchwepheshe buvumela abakhiqizi ukuthi bafinyelele amazinga aphezulu okunemba nokuphindaphinda ekukhiqizeni izingxenye eziyinkimbinkimbi, kungakhathaliseki ukuthi umshini owenziwe ngomshini.

Isidingo sezingxenye zomshini ezinembayo ngezinto ezihlukene siyaqhubeka sikhula njengoba izimboni zifuna ukuthuthukisa ukusebenza nokusebenza kahle kwemikhiqizo yazo. Kungakhathaliseki ukuthi ikhiqiza izingxenye eziyinkimbinkimbi zemishini yezokwelapha noma idala izingxenye eziqinile zemishini yezimboni, ikhono lomshini ohlukahlukene wezinto ezibonakalayo ngokunemba libalulekile ukuze kuhlangatshezwane nezidingo eziguqukayo zemakethe. Njengoba isimo sokukhiqiza sithuthuka, ukuthuthukiswa kwezinto ezintsha nezindlela zokwenza imishini kuzokwandisa amathuba okwenza imishini enembile. Izinqubo ezintsha zokukhiqiza izinto ezingeziwe, ama-nanomaterials, kanye nezinqubo zemishini eyingxube sezilungele ukushintsha indlela izingxenye ezinembayo ezikhiqizwa ngayo, okuvulela abakhiqizi amathuba amasha ukuze basunduze imingcele yalokho okungenzeka emhlabeni wokwenza izinto ngokunemba.

Sengiphetha, izingxenye zomshini ezinembayo ezinezisetshenziswa ezihlukene ziyinkambu eyinkimbinkimbi futhi eguquguqukayo edinga ubuchwepheshe, ukusungula izinto ezintsha, kanye nokuzivumelanisa nezimo. Ikhono lokusebenza ngezinto ezihlukahlukene, kusukela ezinsimbi kuya ezihlanganisweni kuya kumapulasitiki, kubalulekile ukuze abakhiqizi bahlangabezane nezidingo ezihlukahlukene zezimboni zanamuhla. Ngenhlanganisela efanele yezinto zokwakha, ubuchwepheshe, namakhono, ukunemba kwemishini kuzoqhubeka nokudlala indima ebalulekile ekulolongeni ikusasa lokukhiqiza.

Isikhathi sokuthumela: Aug-12-2024