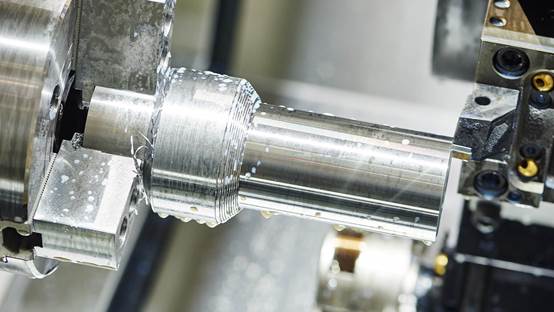

Izinto Ezithinta Ukuba Yinkimbinkimbi Kwengxenye

- Usayizi Wengxenye

Usayizi uwodwa awunqumi ubunkimbinkimbi bengxenye, kodwa ungaba isici. Khumbula, izingxenye eziplaniwe ngezikhathi ezithile ezinkulu azinayo inselele kunezingxenye ezincane, eziyinkimbinkimbi kakhulu. Futhi, cabangela ubukhulu bezimpawu zomuntu ngamunye, njengoba lokhu kuthinta ubukhulu bethuluzi lokusika elizosetshenziswa. Ithuluzi elikhudlwana, elinesivinini esikhulu lokusika lingasusa izinto ngokushesha, linciphise isikhathi somshini.

- Ukucutshungulwa kwengxenye

Inani lemisebenzi, ukungenelela kanye nokuhlola okudingekayo engxenyeni nakho kuzothinta ingxenye eyinkimbinkimbi. Ngokuya ngejometri, ukuqedwa nokubekezelelana njll., ukuhleleka kokusebenza kungase kube yinkimbinkimbi, kudle isikhathi futhi kunemininingwane. Isibonelo, ingxenye eyinkimbinkimbi ingase idinge inani lokuqondiswa kabusha nokungenelela okwenziwa mathupha. Kwesinye isikhathi, i-axis engu-5 noma umshini we-mill-turn ungaba umshini ofaneleka kakhulu, isibonelo, uma kubiza ukukhiqiza noma udinga izindleko ezingaphansi.

- Ukubekezelelana okuyingxenye

Ukubekezelelwa kwengxenye kungase kube nomthelela ekukhethweni komshini we-CNC osetshenzisiwe futhi kungathinta izindleko nesikhathi sokuhola. Ukubekezelelana okufinyelelekayo kuphinde kuthinteke ngezinto ezibonakalayo, isivinini somshini kanye nokusetshenziswa kwamathuluzi. Kalula nje, lapho ukubekezelelana kuqina, ingxenye yakho izobiza kakhulu. Ukubekezelela okuphakeme kuvumela ukunemba okwengeziwe, kodwa kungase futhi kuhilele izinqubo ezengeziwe, ukusebenza, namathuluzi nemishini, ngaleyo ndlela kwenezela ezindlekweni.

Izinhlobo zokuqeda

- Ukuqhunyiswa kobuhlalu

I-Bead Blasting ihilela ukususwa kwanoma iyiphi idiphozithi engaphezulu noma ukungapheleli engxenyeni ethile ukuze kube nesiphetho esifanayo, esibushelelezi. Ubuhlalu obumise okwendilinga buqinisekisa isiphetho esingaguquki futhi ngokuvamile busetshenziselwa ukunikeza ukuqedwa kwe-matt. Ubuhlalu obuhle bungasetshenziselwa ukuqeda okufana ne-satin noma okufiphele.

- I-anodized iqeda

Ukuqedwa kwe-anodized kunikeza i-coating ethile engagugi, ngokuvamile etholakala ngenani lemibala. I-anodizing ngokuvamile isobala, futhi ungqimba ngokuvamile luncane ngakho qiniseka ukuthi ucabangela amamaki omshini we-CNC ngaphezulu.

- Njengomshini

Esinye isiphetho sizoshiya ubulukhuni obungaphezulu njengoba ucezu senziwa ngomshini. Ubulukhuni besevisi obuqondile bunqunywa kusetshenziswa inani lika-Ra. Imvamisa ubulukhuni bobuso bezingxenye zomshini we-CNC yi-Ra 1.6-3.2µm.

Imibiko Yokuhlola I-CMM

Uyini umbiko we-CMM futhi kungani ngiwudinga?

Ukuhlolwa komshini wokulinganisa we-Coordinate (CMM) kuhilela ukusebenzisa umshini wokulinganisa wokuhlanganisa ukuze uhlole ubukhulu bengxenye ukuze kuqinisekiswe ukuthi ingxenye iyahlangabezana yini nezimfuneko ezithile zokubekezelela. Umshini Wokulinganisa Ukuhlanganisa usetshenziselwa ukukala ikhwalithi nezici zento.

Kuzodingeka ukuhlolwa kwe-CMM ukuze kulinganiswe izingxenye eziyinkimbinkimbi ukuze kuqinisekiswe ukuthi ziyahambisana nokucaciswa. Ngokuvamile zizofakwa ezingxenyeni ezinembe kakhulu lapho kudingeka khona ikhwalithi ephezulu nokunemba. Kuleli qophelo, ukuqedwa okubushelelezi kuzobuye kuhlolwe ukuze kuqinisekiswe ukuthi kunembile emidwebeni nasekuklanyweni.

I-CMM isebenza ngokusebenzisa uphenyo olukala amaphuzu endaweni yokusebenza. Izimbazo ezi-3 zakha isistimu yokuxhumanisa yomshini. Enye isistimu isistimu yokudidiyela ingxenye, lapho izimbazo ezi-3 zihlobana/zihambisana nezici kanye nedatha yocezu lokusebenza.

Izinzuzo Zokuhlola I-CMM

Ukuhlolwa kwe-CMM kuzokwenziwa uma kudingeka, futhi ngezinye izikhathi kuyoba isibopho. Imibiko yokuhlolwa kwe-CMM ingonga isikhathi futhi yehlise izindleko ezingaphezulu ngokuqinisekisa ukuthi ingxenye yenziwe ngokunembile ekwakhiweni. Lokhu kuqinisekisa ukuthi akukho lutho olushiywe ngengozi futhi noma yikuphi ukuchezuka ekwakhiweni noma amaphutha atholakala ngaphambi kokuthunyelwa.

Kuye ngemboni, ukuchezuka esimisweni kungase kube inhlekelele (Isibonelo, imboni yezokwelapha, noma imboni ye-aerospace.) Lokhu kuhlola kokugcina kokulawula ikhwalithi kunganikeza iziqinisekiso ngaphambi kokuba ingxenye isayinwe futhi ilethwe kuklayenti.