Isevisi Yezingxenye Zomshini Ze-CNC Eyenziwe Ngokwezifiso

Izingxenye Zomshini ze-CNC

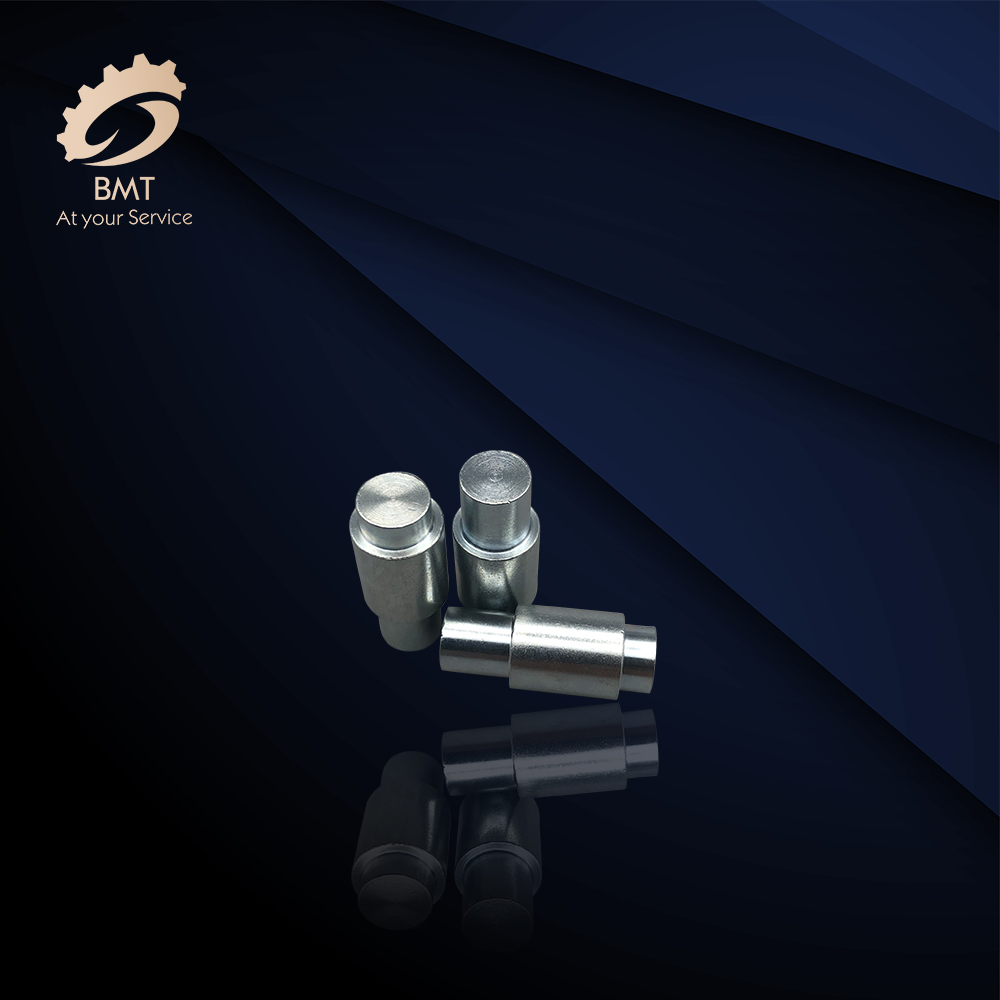

Izingxenye zomshini we-CNC ngokuvamile zingahluka ngobunkimbinkimbi. Kusukela ezingxenyeni ezilula ezihleliwe kuye kumajiyometri anzima kakhulu agobile, kubalulekile ukukhetha umshini olungile we-CNC womsebenzi. Izinhlobo ezahlukene zemishini ye-CNC zikhona futhi zingasetshenziselwa izingxenye ezahlukene.

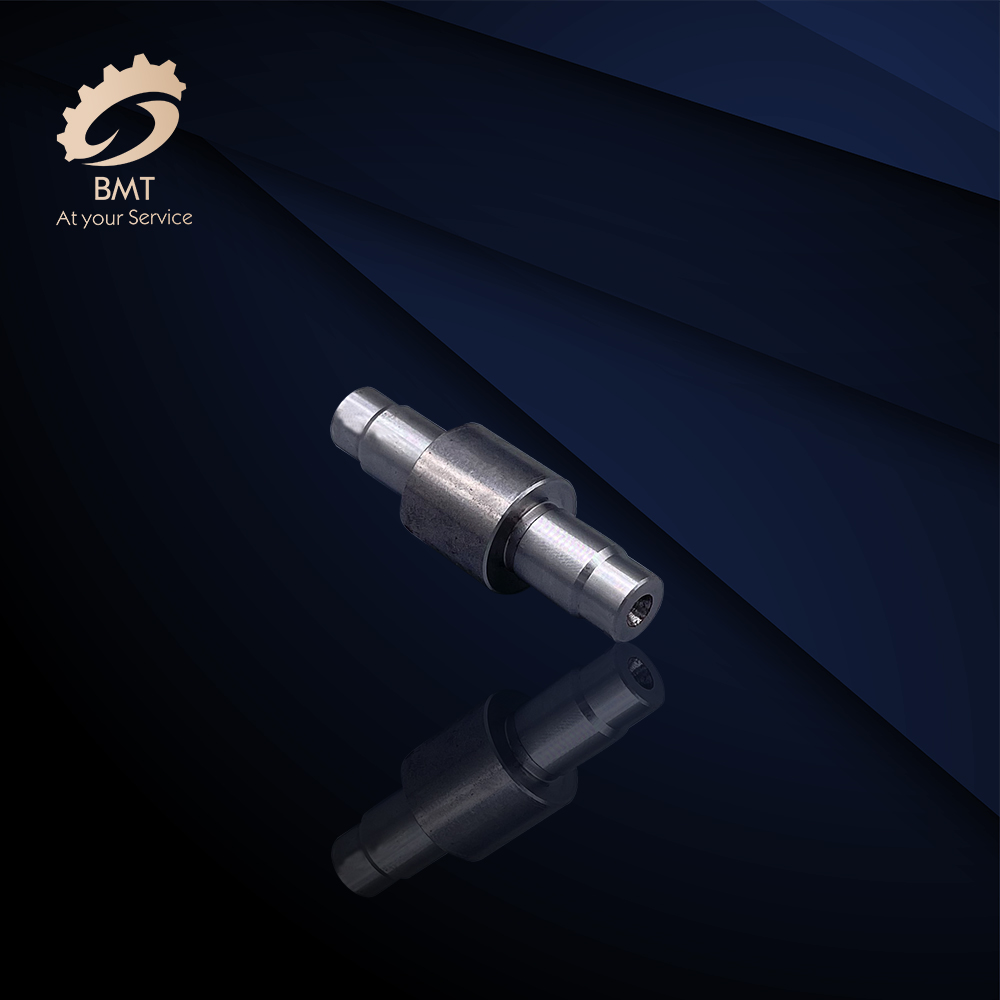

Uhlobo lomshini osetshenzisiwe (i-CNC lathe, umshini wokugaya we-CNC we-axis engu-3 noma isikhungo semishini ye-axis engu-4/5, njll) ngokuvamile izonqunywa ubunkimbinkimbi bengxenye. Ingxenye yobunkimbinkimbi, ijiyomethri nobukhulu buthinta uhlobo lomshini okhethiwe, eduze nokubekezelelana, ukusetshenziswa kokuphela komkhiqizo, kanye nohlobo lwezinto ezibonakalayo.

Izingxenye Zomshini ze-CNC

Izingxenye zomshini we-CNC ngokuvamile zingahluka ngobunkimbinkimbi. Kusukela ezingxenyeni ezilula ezihleliwe kuye kumajiyometri anzima kakhulu agobile, kubalulekile ukukhetha umshini olungile we-CNC womsebenzi. Izinhlobo ezahlukene zemishini ye-CNC zikhona futhi zingasetshenziselwa izingxenye ezahlukene.

Uhlobo lomshini osetshenzisiwe (i-CNC lathe, umshini wokugaya we-CNC we-axis engu-3 noma isikhungo semishini ye-axis engu-4/5, njll) ngokuvamile izonqunywa ubunkimbinkimbi bengxenye. Ingxenye yobunkimbinkimbi, ijiyomethri nobukhulu buthinta uhlobo lomshini okhethiwe, eduze nokubekezelelana, ukusetshenziswa kokuphela komkhiqizo, kanye nohlobo lwezinto ezibonakalayo.

I-CNC Design

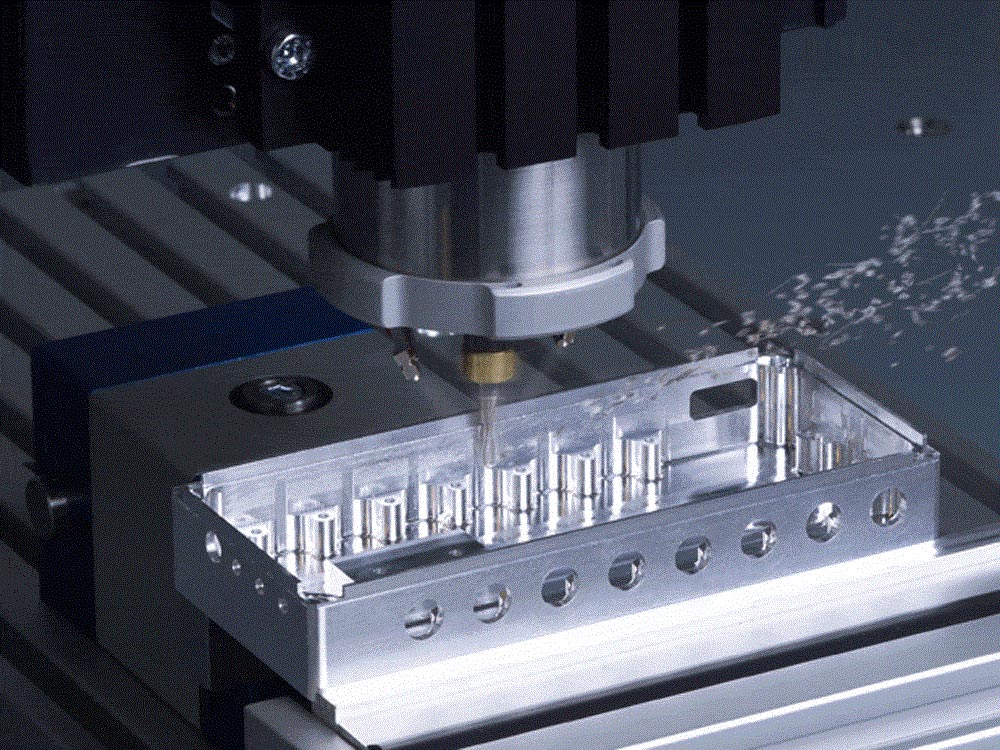

Ukukhuluma kabanzi, ingxenye eyinkimbinkimbi kakhulu izodinga ukucatshangelwa okwengeziwe ngesikhathi somshini ngenxa yokwakheka kwayo, ubukhulu obuthile kanye nezidingo. Onjiniyela bokuklama kufanele ngaso sonke isikhathi, lapho kungenzeka, basebenze ukuze bakhe izingxenye ezilula, ezizikhiqiza kalula ngenkathi ingxenye isenqubweni yokuklama. Ukuklama okulula, kuzoba lula ukwenza, futhi, ngokuzenzakalelayo, izindleko eziphezulu zizoba zishibhile.

Abaklami bemishini bahlale becabangela indlela yokudala imiklamo edinga izingxenye ezimbalwa ngenkathi ihlinzeka ngokusebenza okuphezulu. Lokhu kungehlisa izindleko ngenkathi kuqinisekisa ukusebenza kahle kanye nokuphumayo okuphezulu.

I-CNC Design

Ukukhuluma kabanzi, ingxenye eyinkimbinkimbi kakhulu izodinga ukucatshangelwa okwengeziwe ngesikhathi somshini ngenxa yokwakheka kwayo, ubukhulu obuthile kanye nezidingo. Onjiniyela bokuklama kufanele ngaso sonke isikhathi, lapho kungenzeka, basebenze ukuze bakhe izingxenye ezilula, ezizikhiqiza kalula ngenkathi ingxenye isenqubweni yokuklama. Ukuklama okulula, kuzoba lula ukwenza, futhi, ngokuzenzakalelayo, izindleko eziphezulu zizoba zishibhile.

Abaklami bemishini bahlale becabangela indlela yokudala imiklamo edinga izingxenye ezimbalwa ngenkathi ihlinzeka ngokusebenza okuphezulu. Lokhu kungehlisa izindleko ngenkathi kuqinisekisa ukusebenza kahle kanye nokuphumayo okuphezulu.

Ubunkimbinkimbi bezingxenye buhlala bucatshangelwa abaklami bemishini, futhi izingxenye ezisebenza kahle kakhulu eziklanywe kahle zizocabangela isikhathi sokuhola somshini. Ubunjiniyela obunembayo bunganciphisa ubungozi obuvame ukubangelwa iphutha lomuntu. Amaphutha amancane esilinganisweni, ekusebenzeni noma ekukhiqizeni angaholela ekutheni amaphrojekthi kanye nemikhiqizo ibe sengozini ngokuphelele. Unalokhu engqondweni, kufanelekile ukuqinisekisa ukuthi usebenzisana nabaklami abanolwazi, onjiniyela nabakhiqizi.

Sengikushilo lokho, kuzodingeka ukwenziwa kwemishini eyinkimbinkimbi ye-CNC, lapho amazinga aphezulu okunemba nokuqeda kungase kubangele isikhathi eside sokuhola. Umthetho ojwayelekile ukuthi i-4/5 axis CNC Machining izodingeka engxenyeni eyinkimbinkimbi kanye nokwakheka okuyinkimbinkimbi. Lokhu kungenxa yokuthi umshini ungasebenza kuma-engeli/ama-axe ahlukene angu-4/5 ukuze ufinyelele umumo wokugcina, kunokuba amabili noma amathathu asebenze ku-X kanye no-Y kuphela.

Ngokuhlanganisa ezinye izimbazo ezintathu, A, B kanye no-C, izingxenye ezinembe kakhudlwana neziyinkimbinkimbi zingenziwa ngomshini, ngaphandle kwesidingo sokuphinda uqondise ingxenye ngesandla ngaphakathi komshini. Iqiniso lokuthi i-5 axis CNC milling inganikeza 'ukusetha okukodwa' kuyinzuzo enkulu, enciphisa isikhathi.

Ukunemba okuphezulu kwamathuluzi kanye nabaqhubi abanolwazi kungasiza ekuqinisekiseni ukuthi ingxenye edingekayo ingakhiqizwa ngemiphumela enembe kakhulu kanye nesikhathi sokuhola esisheshayo. Kuhlale kufanelekile ukuthintana nomkhiqizi onolwazi ukuze ubuze ngamakhono abo okwenza imishini nokuthi angakusiza kanjani kangcono kakhulu. Kwa-BMT, singanikeza Ingcaphuno Yamahhala Yamahora angu-24; bona ukuthi singasiza kanjani iphrojekthi yakho namuhla. Yithole.