Imibuzo Yangempela Ye-CNC Machining Processing

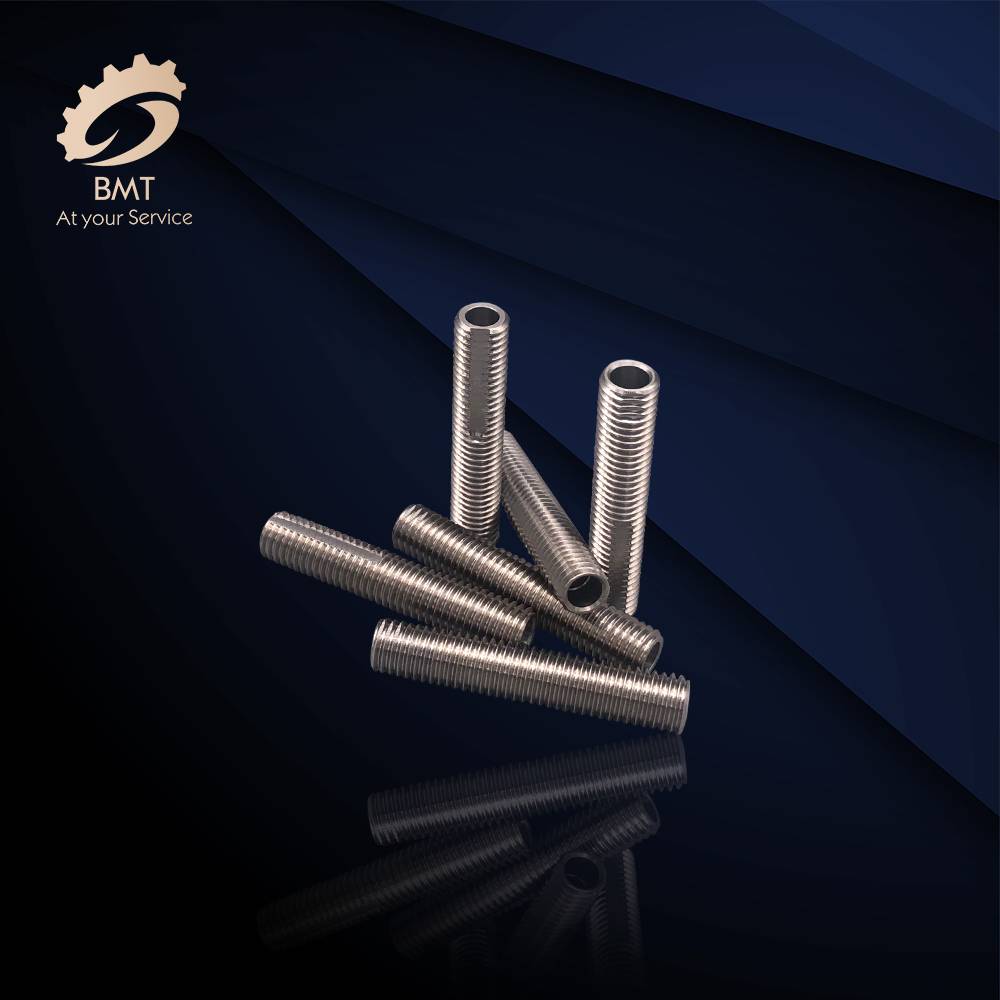

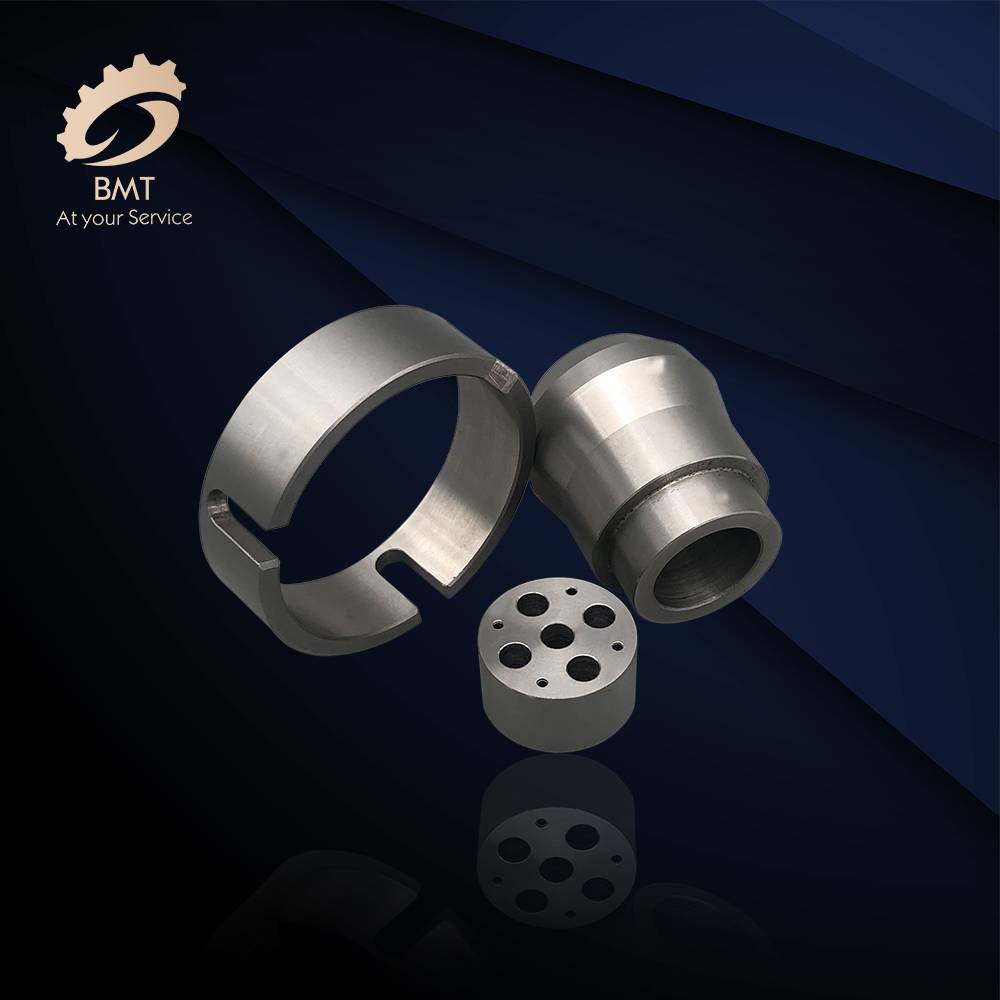

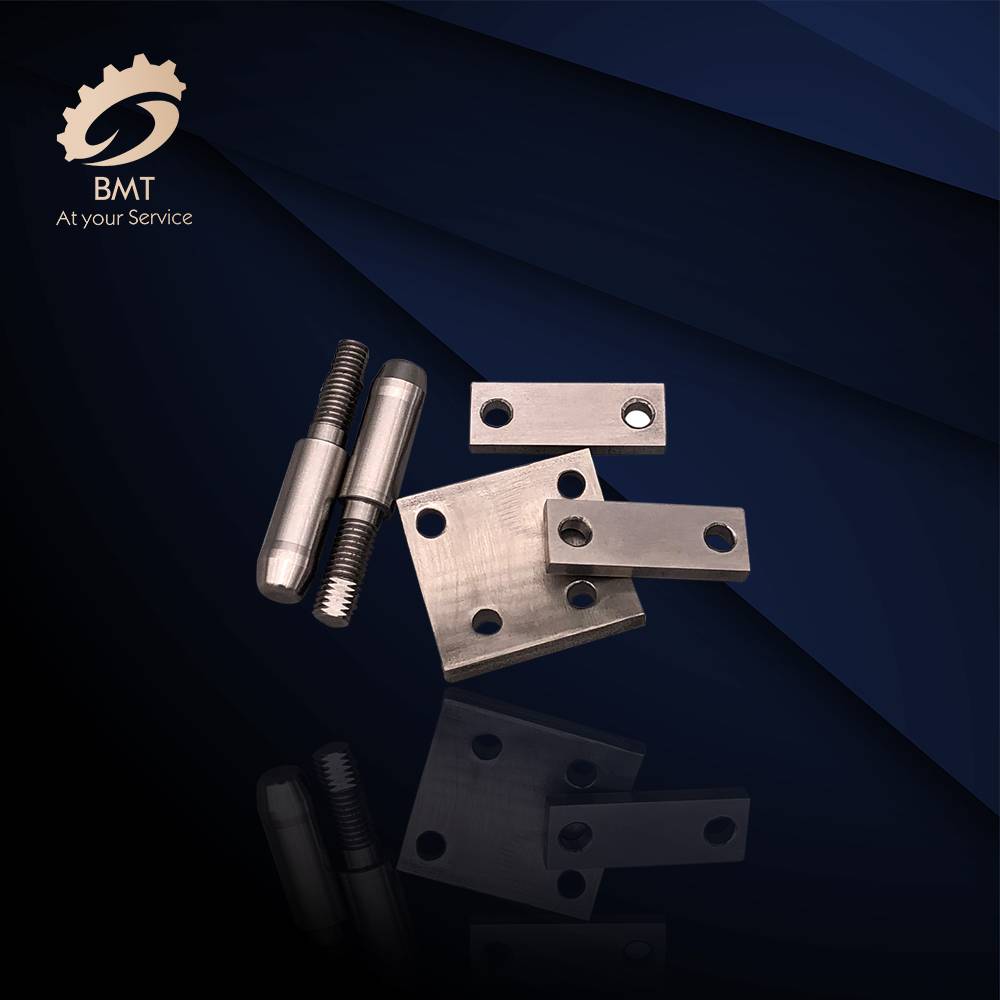

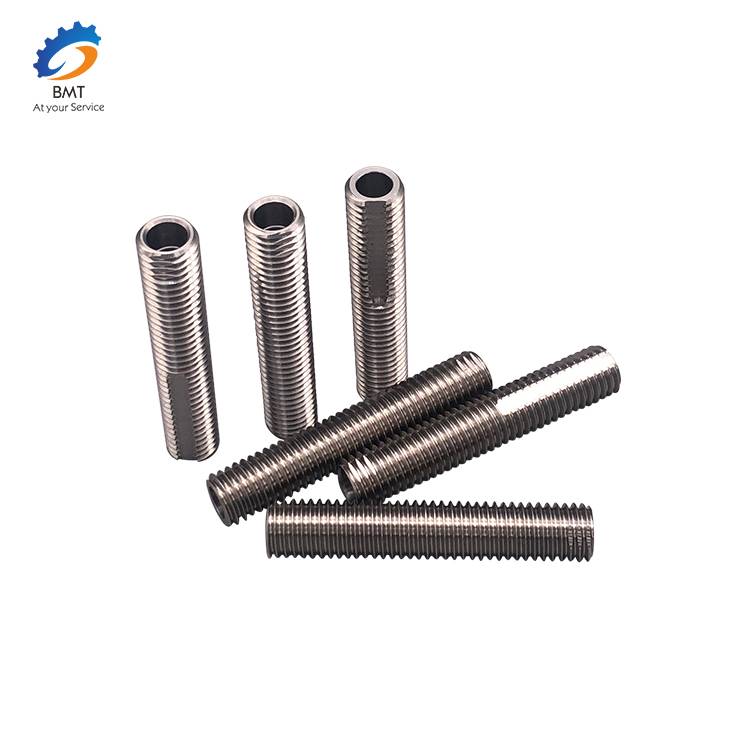

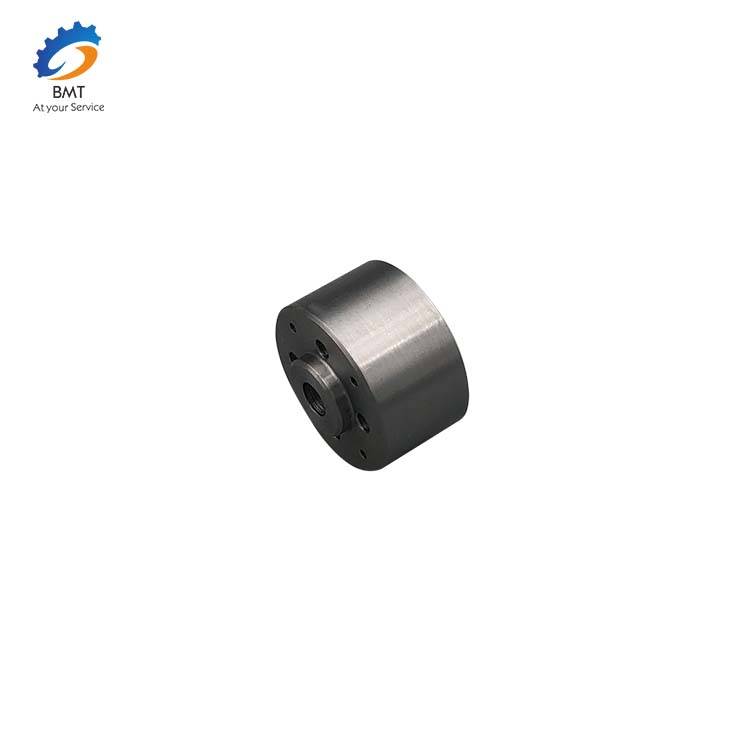

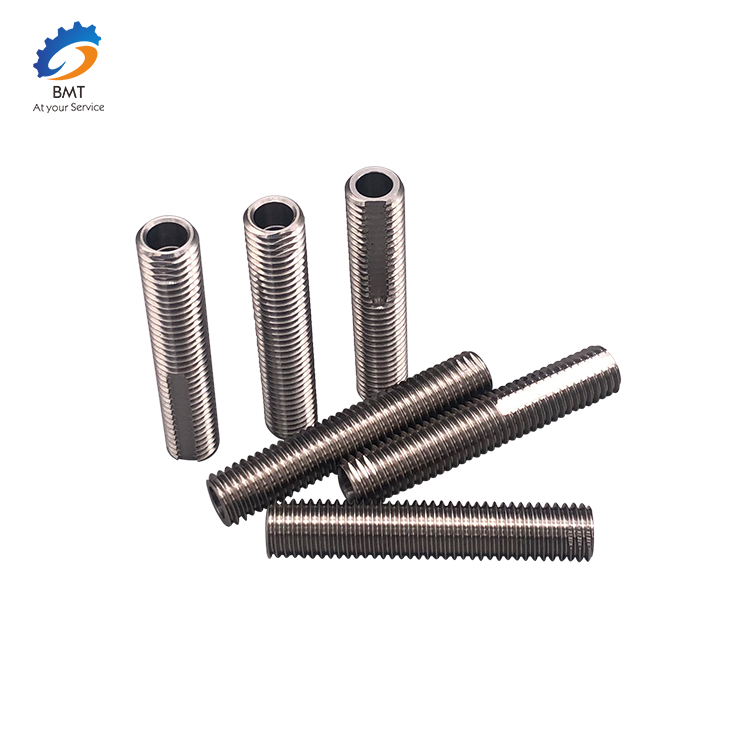

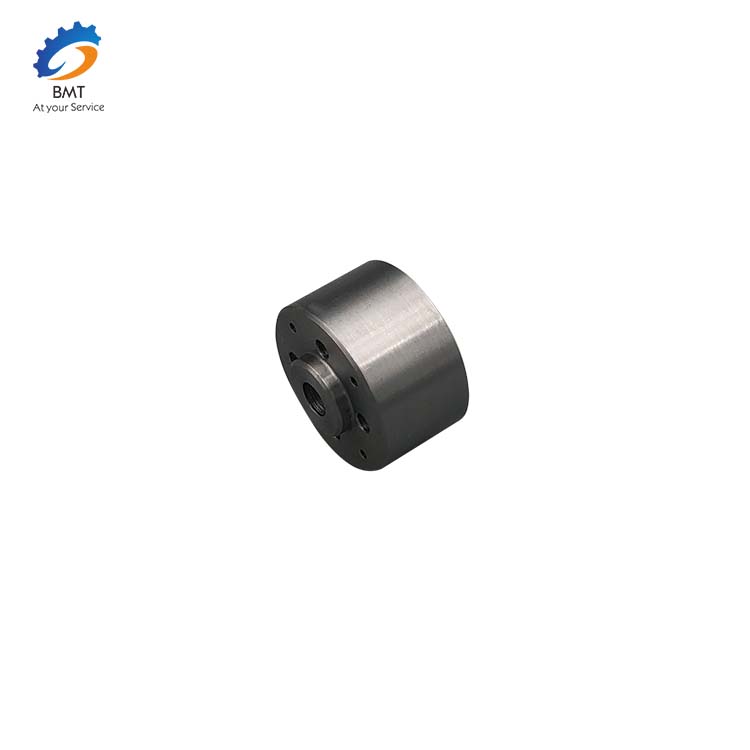

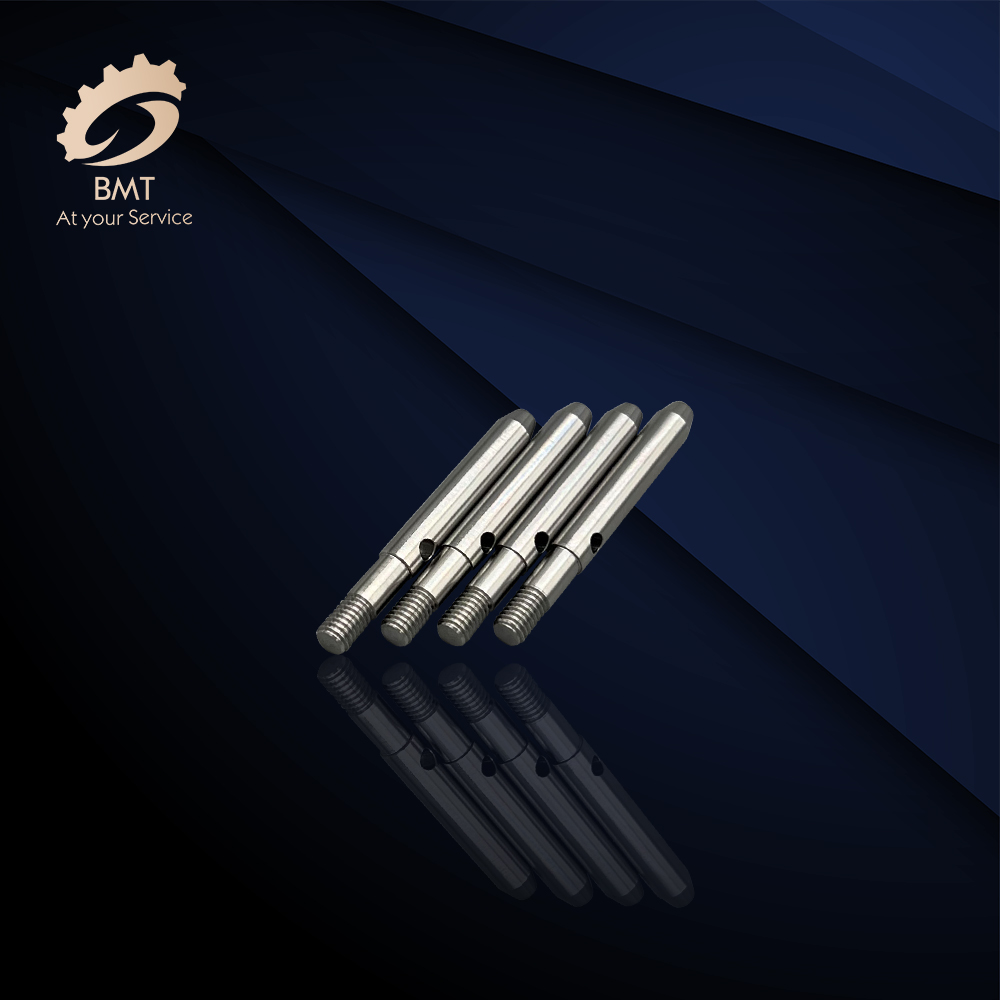

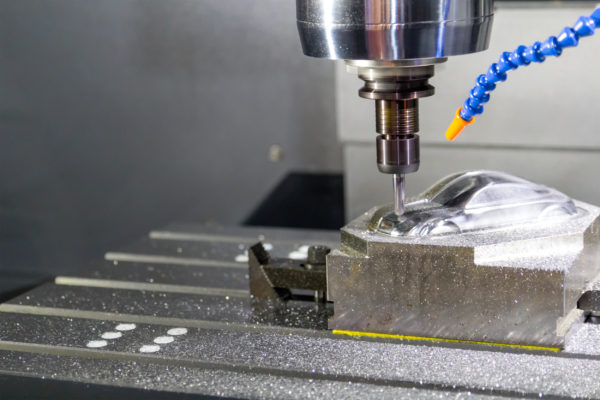

Ukunemba kwemishini kungaletha noma iyiphi inqubo yokukhiqiza ezingeni elilandelayo. Ingenza izimanga ngokusebenza kahle, inciphise isikhathi sokushintsha, futhi yehlise izindleko zokukhiqiza. Ubani owazi lokhu kangcono kunomunye wabakhiqizi abakhulu baseChina be-CNC Turning and Milling abanolwazi lweminyaka eyi-15 ngaphansi kwebhande layo? I-BMT ibilokhu ihlinzeka ngezingxenye ezinembayo ezihlukile ezimbonini kusukela ngaleso sikhathi.

Ukuvimbela nokulawula ukudlidliza kokucubungula imishini:

Ukuqeda noma ukwenza buthaka izimo ezikhiqiza ukudlidliza kwemishini; Ukwenza ngcono izici eziguquguqukayo zesistimu yenqubo ukuthuthukisa ukuzinza kwesistimu yenqubo kusetshenziswa amadivaysi ahlukahlukene wokudambisa ukudlidliza.

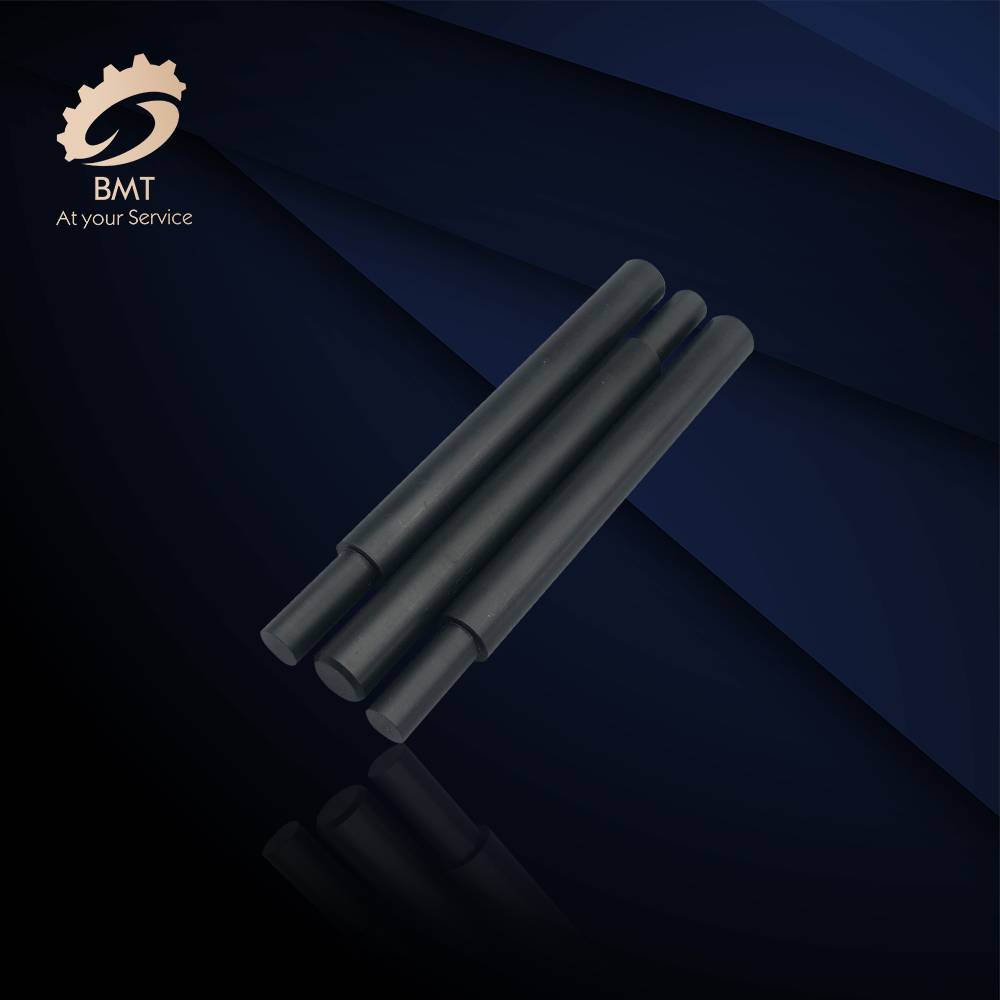

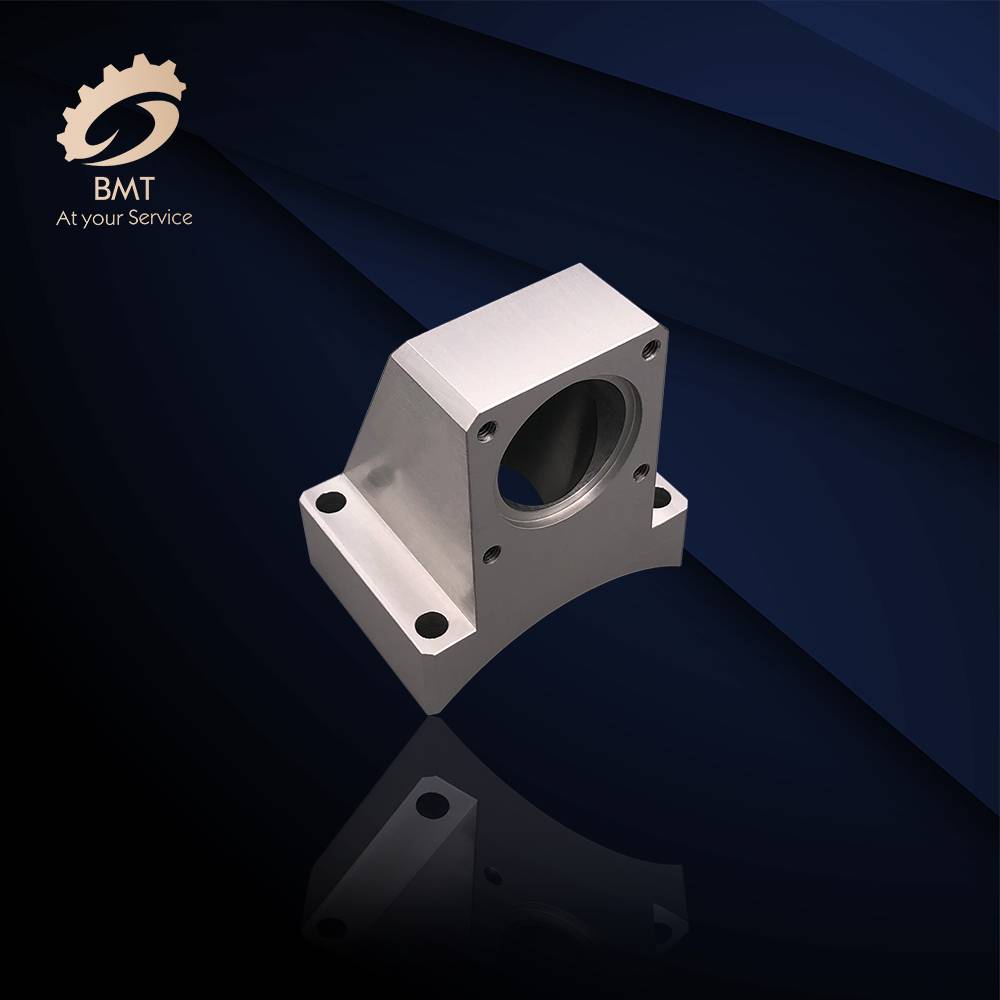

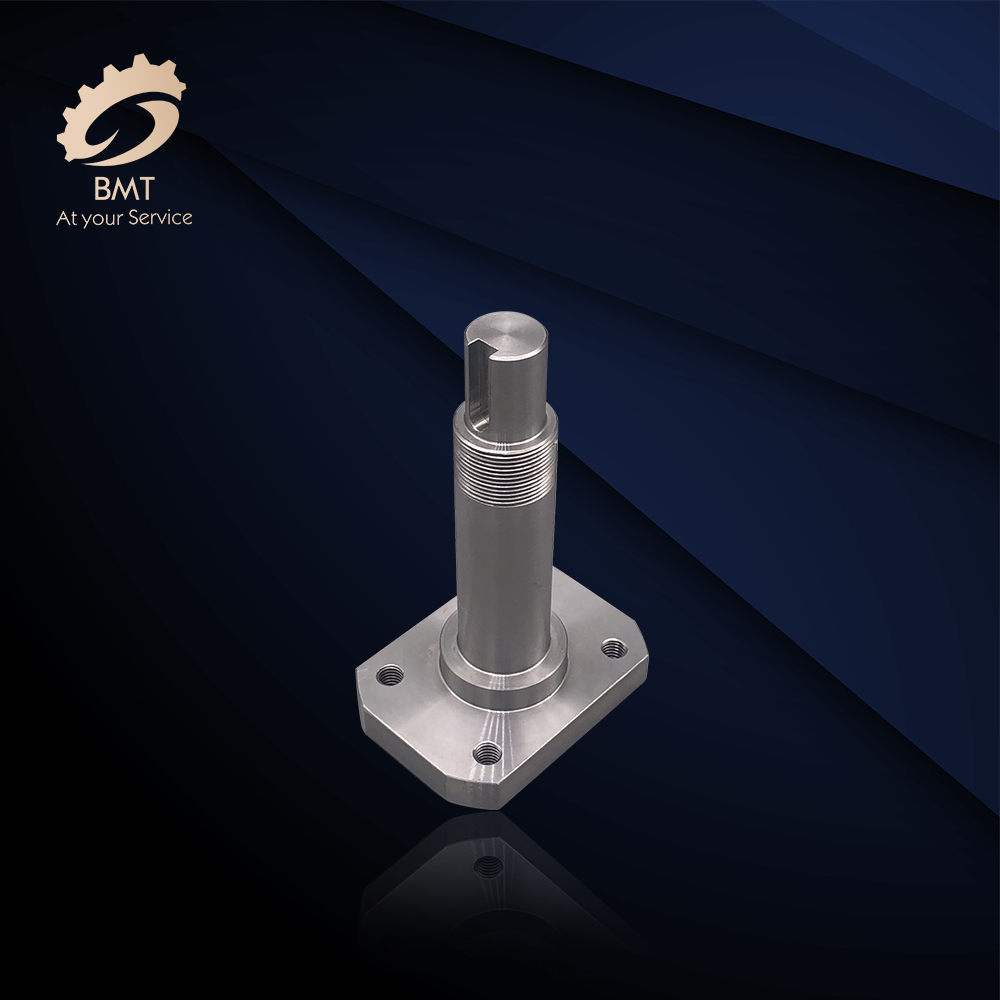

Incazelo Yomkhiqizo

Kungani Khetha Izingxenye Zethu Zemishini Ye-CNC?

Umgomo wokukhetha ibhentshimakhi engalungile? Isimiso sokukhetha ibhentshimakhi enhle?

Ibhentshimakhi engahluziwe:

1. Umgomo wokuqinisekisa izidingo zesikhundla esifanayo;

2. Umgomo wokuqinisekisa ukusatshalaliswa okufanele kwemvume yomshini wendawo yomshini;

3. Umgomo we-workpiece clamping elula;

4. Isimiso sokuthi i-datum eqinile akufanele iphinde isetshenziswe ngokujwayelekile

Ibhentshimakhi enhle:

1. Umgomo wokugqagqana kwedatha;

2. Isimiso sokuma esihlanganisiwe;

3. Umgomo wokufanisa;

4. Umgomo wokuzisebenzela wena ngokwakho;

5. Kulula ukubopha isimiso.

Yiziphi izimiso zokulandelana kwenqubo?

a) Okokuqala cubungula izinga ledatha, bese ucubungula ezinye izindawo;

b) Engxenyeni yamacala, indawo engaphezulu icutshungulwa kuqala, bese imbobo icutshungulwa;

c) Indawo engaphezulu icutshungulwa kuqala, bese iphinda icutshungulwe kamuva;

d) Hlela inqubo yokwenza ama-roughing kuqala, bese uqedela inqubo.

Indlela yokuhlukanisa isigaba sokucubungula? Yiziphi izinzuzo zokuhlukanisa izigaba zokucubungula?

Isigaba sokucubungula:

1) Isiteji somshini onzima

2) Isigaba sokuqeda kancane

3) Ukuqeda isigaba

4) Ukunemba kokuqeda isigaba

Ingaqinisekisa isikhathi esanele sokuqeda ukuwohloka kokushisa nokucindezeleka okusalayo okubangelwa umshini onzima, ukuze kuthuthukiswe ukunemba komshini olandelayo. Ngaphezu kwalokho, esigabeni sokucutshungulwa okungalungile kutholwe amaphutha angenalutho akudingeki ukuthi acutshungulwe esigabeni esilandelayo sokucubungula, ukugwema imfucuza. Ngaphezu kwalokho, ukusetshenziswa okunengqondo kwemishini, amathuluzi omshini wokunemba okuphansi wamathuluzi omshini wokunemba wokunemba ukuze aqedele, ukuze kugcinwe izinga lokunemba lamathuluzi omshini wokunemba; Ukuhlelwa okunengqondo kwezinsiza zabantu, abasebenzi bezobuchwepheshe obuphezulu abasebenza ngokunemba ukucutshungulwa kwe-ultra-precision, okubaluleke kakhulu ukuqinisekisa ikhwalithi yemikhiqizo, ukuthuthukisa izinga lobuchwepheshe.