I-Titanium ne-Titanium Alloy Forgings

Ama-alloys e-Titanium ne-titanium anezinzuzo zokuminyana okuphansi, amandla athile aphezulu kanye nokumelana nokugqwala okuhle, futhi asetshenziswa kabanzi emikhakheni ehlukahlukene.

I-Titanium Forging iyindlela yokwakha esebenzisa amandla angaphandle ezikhaleni zensimbi ye-titanium (Ngaphandle kwamapuleti) ukuze kukhiqizwe ukuguqulwa kwepulasitiki, ukushintsha usayizi, ukuma, nokwenza ngcono ukusebenza. Isetshenziselwa ukwenza izingxenye zemishini, izinto zokusebenza, amathuluzi noma izikhala. Ngaphezu kwalokho, ngokwephethini yokunyakaza yesilayidi kanye namaphethini okunyakaza okuma mpo nakwezingqimba kwesilayidi (Ngokwenza izingxenye ezincane, ukuthambisa nokupholisa, kanye nokwakhiwa kwezingxenye zokukhiqiza ezinesivinini esikhulu), ezinye izinkomba zokunyakaza zingandiswa usebenzisa idivayisi yesinxephezelo.

Izindlela ezingenhla zihlukile, futhi amandla okubumba adingekayo, inqubo, izinga lokusebenzisa impahla, okukhiphayo, ukubekezelelana kobukhulu, kanye nezindlela zokuthambisa nezindlela zokupholisa nazo zihlukile. Lezi zici nazo ziyizici ezithinta izinga lokuzenzekelayo.

I-Forging yinqubo yokusebenzisa i-plasticity yensimbi ukuze uthole inqubo yokwenza ipulasitiki enesimo esithile kanye nezakhiwo zesakhiwo se-blank ngaphansi komthelela noma ingcindezi yethuluzi. Ukuphakama kokukhiqiza ukukhiqiza ukuthi akukwazi nje ukuthola ukuma kwezingxenye zemishini, kodwa futhi kuthuthukise isakhiwo sangaphakathi sezinto ezibonakalayo futhi kuthuthukise izakhiwo zemishini yezingxenye zemishini.

1. Ukuqamba Kwamahhala

Ukufoja kwamahhala kuvame ukwenziwa phakathi kwamafalethi amabili noma isikhunta ngaphandle kwesikhala. Amathuluzi asetshenziswa ekwenziweni kwamahhala alula ngokuma, ayavumelana nezimo, mafushane emjikelezweni wokukhiqiza futhi aphansi ngezindleko. Kodwa-ke, amandla okusebenza aphakeme, ukusebenza kunzima, ukukhiqiza kuphansi, ikhwalithi ye-forging ayikho phezulu, nesibonelelo somshini sikhulu. Ngakho-ke, kufanelekile kuphela ukusetshenziswa lapho kungekho zidingo ezikhethekile ekusebenzeni kwezingxenye futhi inani lezicucu lincane.

2. Vula i-Die Forging (I-Die Forging with Burrs)

Okungenalutho kukhubazekile phakathi kwamamojula amabili anezimbotshana eziqoshiwe, imbobo ivalwe ngaphakathi emgodini, futhi insimbi eyeqile igeleza iphuma egebeni elincane phakathi kwalokhu okubili okufayo, yenze ama-burrs azungeze i-forging. Ngaphansi kokumelana kwesikhunta kanye nama-burrs azungezile, insimbi iphoqeleka ukuba icindezelwe esimweni somgodi wokubumba.

3. I-Die Forging evaliwe (i-Die Forging ngaphandle kwama-Burrs)

Ngesikhathi senqubo yokufaka i-die forging evaliwe, awekho ama-burrs aguquguqukayo aqondana nendawo yokunyakaza kwe-die akhiwayo. Umgodi wokudayela ovaliwe unemisebenzi emibili: owokwenza okungenalutho, omunye owokuqondisa.

4. I-Extrusion Die Forging

Ukusebenzisa indlela ye-extrusion yokufoja, kunezinhlobo ezimbili zokufoja, i-extrusion eya phambili kanye ne-reverse extrusion. I-Extrusion die Forging ingakha izingxenye ezihlukahlukene ezingenalutho neziqinile, futhi ingathola ama-forging anembayo ephezulu yejometri kanye nesakhiwo sangaphakathi esiminyene.

5. I-Multi-Directional Die Forging

Kwenziwa emshinini wokubumba wokufa oneziqondiso eziningi. Ngaphezu kokubhoboza okuqondile kanye nomjovo wepulaki, umshini wokubumba wokufa oneziqondiso eziningi unama-plunger amabili avundlile. I-ejector yayo nayo ingasetshenziselwa ukubhoboza. Ingcindezi ye-ejector iphakeme kunaleyo yomshini wokucindezela ojwayelekile we-hydraulic. Ukuba mkhulu. Ku-multi-directional die forging, isilayidi sisebenza ngokushintshana nangokuhlanganyela kucezu lokusebenza ukusuka eziqondisweni eziqondile nezivundlile, futhi i-punch eyodwa noma ngaphezulu yokubhoboza isetshenziselwa ukwenza insimbi igeleze iye ngaphandle isuka enkabeni yomgodi ukuze kuzuzwe inhloso yokugcwalisa umgodi.

6. Ukuqamba Okuhlukene

Ukuze wenze ama-forging amakhulu ahlanganisiwe kungcindezi ekhona ye-hydraulic, izindlela zokubumba ze-segmental die faging ezifana ne-segment die forging kanye ne-shim plate die forging zingasetshenziswa. Isici sendlela yokwenza ingxenye ye-die forging ukucubungula ucezu lokubumba ngesiqeshana, ukucubungula ingxenye eyodwa ngesikhathi, ngakho-ke i-tonnage yemishini edingekayo ingaba encane kakhulu. Ngokuvamile, le ndlela ingasetshenziselwa ukucubungula ama-forging amakhulu kakhulu emshinini wokunyathelisa we-hydraulic ophakathi nendawo.

7. I-Isothermal Die Forging

Ngaphambi kokubumba, isikhunta sishiswa ekushiseni kokubumba kokungenalutho, futhi izinga lokushisa lesikhunta kanye nokungenalutho lihlala lifana kuyo yonke inqubo yokubumba, ukuze kutholakale inani elikhulu lokuguqulwa ngaphansi kwesenzo samandla amancane okuguqula. . I-Isothermal die forging kanye ne-isothermal superplastic die forging zifana kakhulu, umehluko ukuthi ngaphambi kokwenza ukufa, okungenalutho kudinga ukufakwa kwe-superplasticized [i] ukuze kube nezinhlamvu ezilinganayo [ii].

Inqubo yokubumba i-Titanium alloy isetshenziswa kabanzi ekukhiqizeni izindiza kanye ne-aerospace (I-Isothermal Die Forging Processiye yasetshenziswa ekukhiqizeni izingxenye zenjini nezingxenye zesakhiwo sezindiza), futhi iya ngokuya iduma emikhakheni yezimboni njengezimoto, amandla kagesi, nemikhumbi.

Njengamanje, izindleko zokusetshenziswa kwezinto ze-titanium ziphezulu uma kuqhathaniswa, futhi izinkambu eziningi zabantu abavamile azikaqapheli ngokugcwele ubuhle be-titanium alloys. Ngokuthuthuka okuqhubekayo kwesayensi, ukulungiswa kobuchwepheshe bomkhiqizo we-titanium ne-titanium alloy kuzoba lula futhi izindleko zokucubungula zizokwehla futhi zibe phansi, futhi ubuhle bemikhiqizo ye-titanium ne-titanium alloy izogqanyiswa emikhakheni eminingi eminingi.

Using extrusion indlela ye-die forging, kunezinhlobo ezimbili zokuqamba, i-Forward Extrusion kanye ne-Reverse Extrusion. I-Extrusion Die Forging ingakha izingxenye ezihlukahlukene ezingenalutho neziqinile, futhi ingathola ama-forging anembayo ephezulu yejometri kanye nesakhiwo sangaphakathi esiminyene.

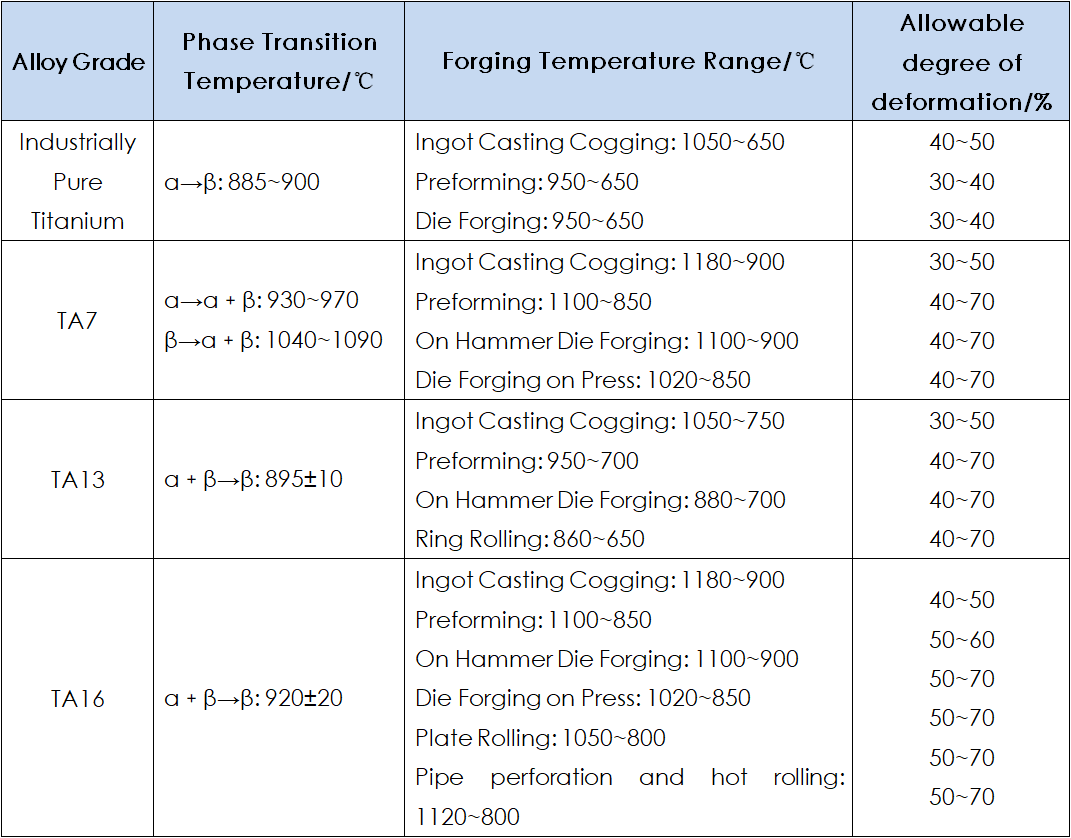

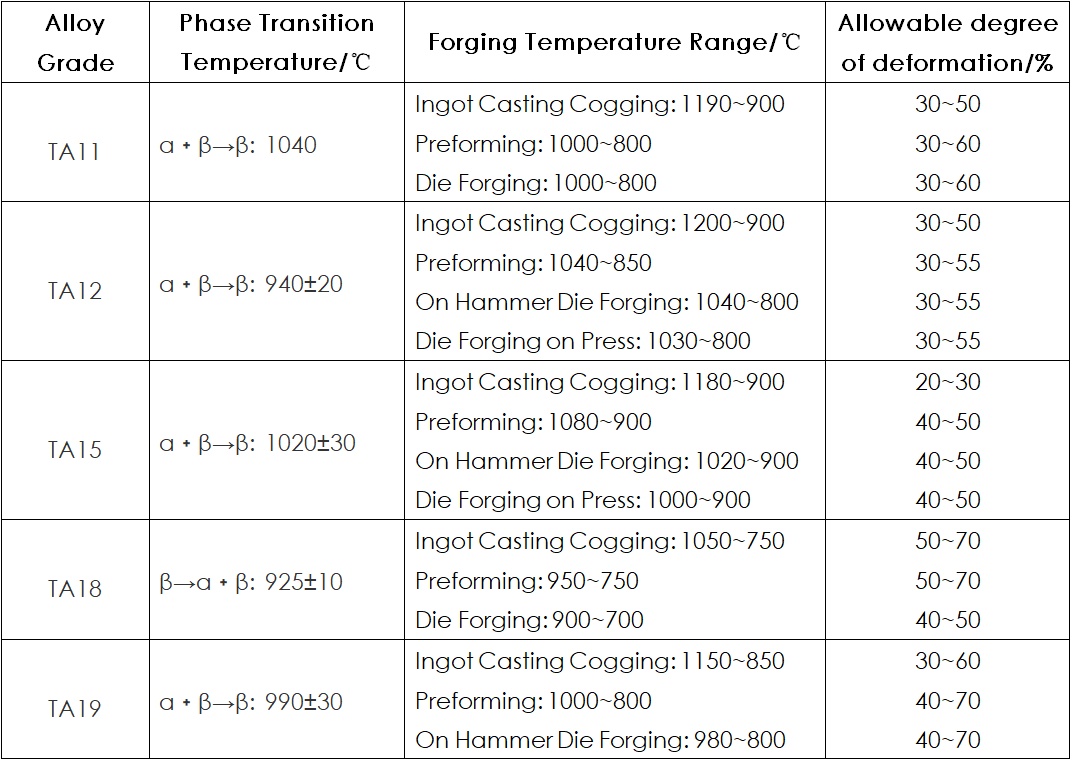

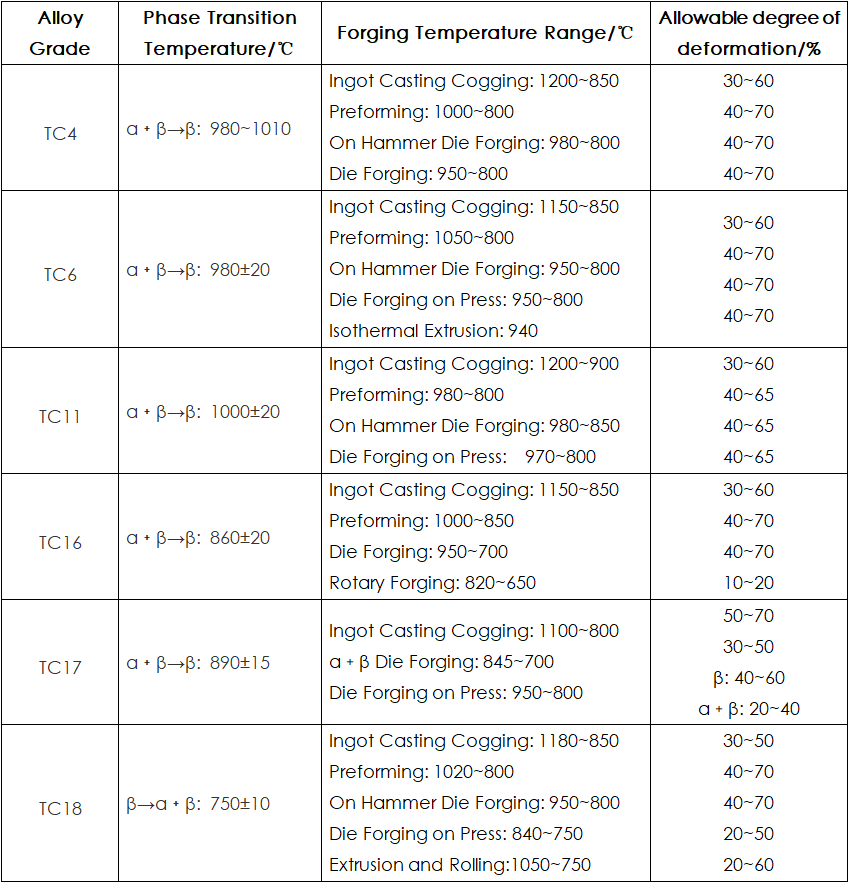

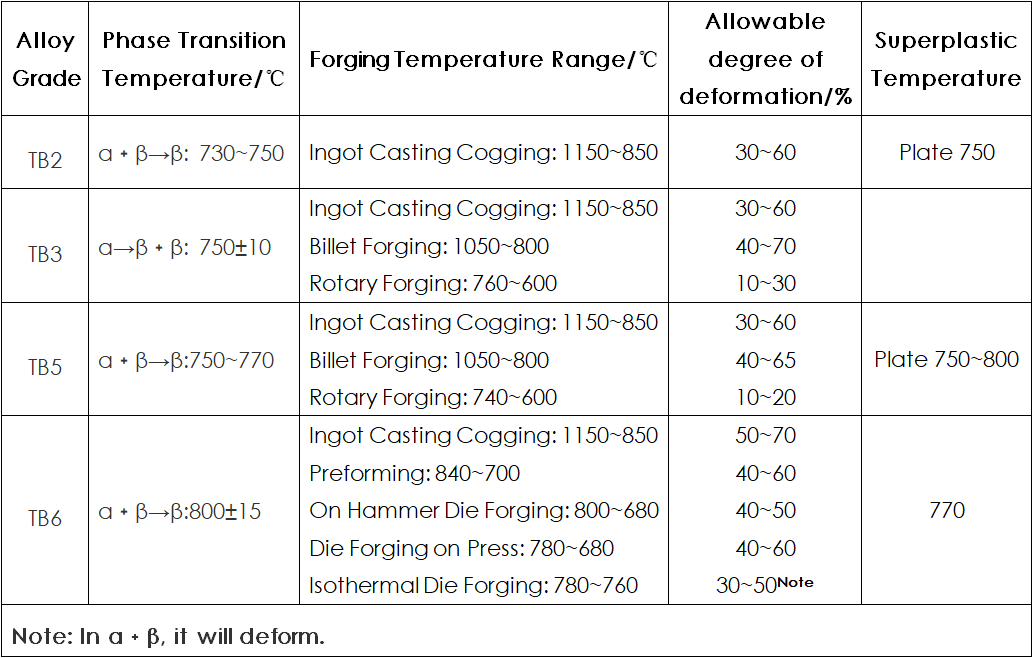

Ngokocwaningo lwethiyori kanye nesipiliyoni sokukhiqiza kwefekthri, idatha yokusebenza kwenqubo yokubumba yohlobo lwe-α, uhlobo oluseduze-α, uhlobo lwe-α﹢β-nohlobo oluseduze lwe-β-alloys ye-titanium ifinyezwa kuThebula 1 kuya kuThebula lesi-4, ngokulandelana.

Kusukela kudatha ekuThebula 1 kuya kuThebula 4, kungabonakala ukuthi izinga lokushisa le-billeting lama-ingots amaningi we-titanium alloy liphakathi kuka-1150°C kuya ku-1200°C, futhi izinga lokushisa lokuqala lokuqamba lezinye izingothi ze-titanium alloy likububanzi. kusuka ku-1050 ° C kuya ku-1100 ° C; Lezi zindawo ezimbili zokushisa zombili zitholakala endaweni yesigaba esingu-β, futhi eyokuqala iphakeme kunezinga lokushisa lokushintsha kwesigaba ngezizathu eziningi.

Okokuqala, i-alloy inokwakheka okuphezulu kanye nokumelana nokuguquguquka okuphansi endaweni yesigaba se-β. Ukuze ulwele isikhathi eside sokubumba, Kuyasiza ukuthuthukisa ukukhiqiza; okwesibili, i-billet yokuqhakaza kwe-ingot inikezwa ngokuyinhloko njengendawo engenalutho yokufoja. Ngemuva kokubumba ngezinga elikhulu lokuguqulwa, isakhiwo singathuthukiswa ngaphandle kokuphazamisa ukusebenza kokubumba. Ngakho-ke, inqubo enokukhiqiza okuphezulu ikhethiwe.

Kusukela kudatha ekuThebula 1 kuya kuThebula 4, kungabonakala ukuthi izinga lokushisa lokuqala lokubumba emshinini wokunyathelisa alikho nje eliphansi kakhulu kunezinga lokushisa lokuqala lokubumba le-ingot billet, kodwa futhi liphansi kunezinga lokushisa lokushintsha kwesigaba se-α/β. ngo-30℃~50℃. Iningi le-titanium Izinga lokushisa le-die forging le-alloy likububanzi obungu-930℃~970℃, okuwukuqinisekisa ukuwohloka esifundeni sesigaba se-α﹢β ukuze kutholwe i-microstructure edingekayo kanye nezakhiwo ze-forging. Njengoba ukwakhiwa kwesando sokubumba kudinga amagalelo amaningi futhi isikhathi sokusebenza siside, izinga lokushisa lokushisisa le-die forging lama-forging alo aqediwe linganyuswa ngokufanelekile ngo-10℃~20℃ kunalelo lokufoja ngokucindezela. Kodwa-ke, ukuze kuqinisekiswe ukwakheka kanye nezakhiwo zemishini ye-titanium alloy eqediwe yokuqamba, Ngakho-ke, izinga lokushisa lokugcina lokubumba lenqubo yokubumba kufanele lilawulwe esifundeni sezigaba ezimbili ezingu-α﹢β.

Kungase futhi kubonakale kudatha ekuThebula 1 kuya kuThebula 4 ukuthi izinga lokushisa lokuqala lokubumba lama-preforms amaningi we-titanium alloy lingaphezulu kancane noma eduze kwezinga lokushisa lokushintsha kwesigaba. Izinga lokushisa lokuqala le-α/β lenqubo yenguquko elifana nokwenza kuqala liphansi kunezinga lokushisa eliqhakazayo le-ingot, futhi liphakeme kunezinga lokushisa lokuqala lokubumba le-die forging. I-Deformation kule ndawo yokushisa ayigcini nje ukunakekela ukukhiqiza, kodwa futhi ilungiselela isakhiwo esihle sokubumba.

Ithebula 1 Idala idatha yokusebenza kwenqubo yohlobo lwe-α-titanium

Ithebula 2 Idala idatha yokusebenza kwenqubo ye-alpha yohlobo lwe-titanium alloy

Ithebula 3 Idala idatha yokusebenza kwenqubo ye-α﹢β titanium ingxubevange

Ithebula 4 Ihlanganisa idatha yokusebenza kwenqubo ye-alloy eseduze yohlobo lwe-titanium

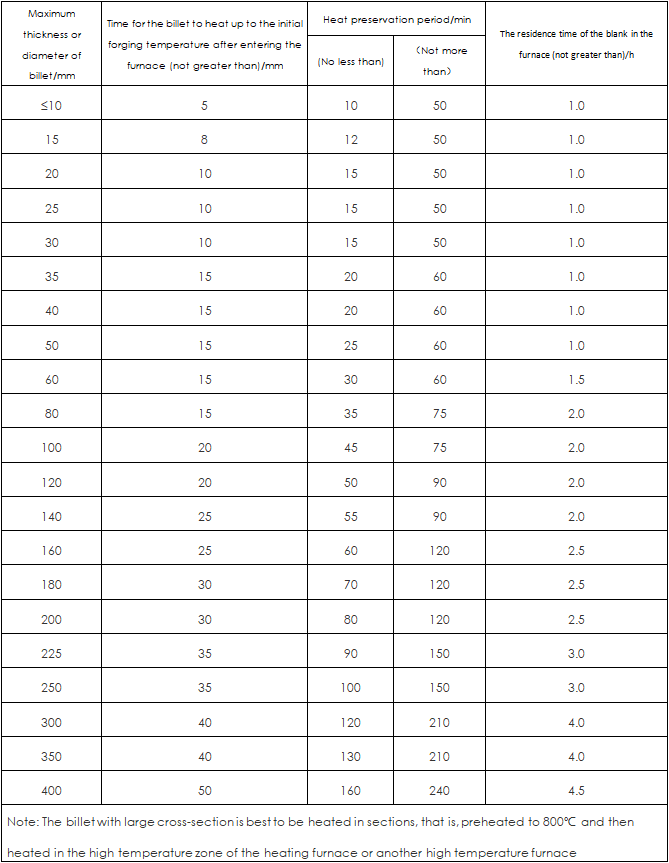

Ithebula 5 Ukushisisa nokubamba isikhathi sezikhala ze-titanium alloy

I-BMT ikhethekile ekukhiqizeni i-premium titanium forging kanye ne-titanium alloy forging enamandla amakhulu kakhulu emishini, ukuqina, ukumelana nokugqwala, ukuminyana okuphansi kanye nokuqina okuphezulu. Ukukhiqizwa okujwayelekile kwemikhiqizo ye-BMT ye-titanium kanye nenqubo yokuhlonza kunqobe kokubili ubunzima bezobuchwepheshe kanye nobunzima bomshini wokukhiqiza ukubumba i-titanium.

Ukukhiqizwa kokubumba kwe-titanium okunembayo kwekhwalithi ephezulu kusekelwe ekwakhiweni kwenqubo yobungcweti kanye nendlela eqhubekayo kancane kancane. I-BMT titanium forging ingasetshenziswa ebangeni ukusuka esakhiweni esisekela uhlaka lwamathambo kuya ekubunjweni kosayizi omkhulu we-titanium ezindizeni.

I-BMT titanium forgings isetshenziswa kakhulu ezimbonini eziningi, ezifana ne-aerospace, ubunjiniyela be-offshore, uwoyela negesi, ezemidlalo, ukudla, izimoto, njll. Umthamo wethu wokukhiqiza wonyaka ungafika kumathani ayi-10,000.

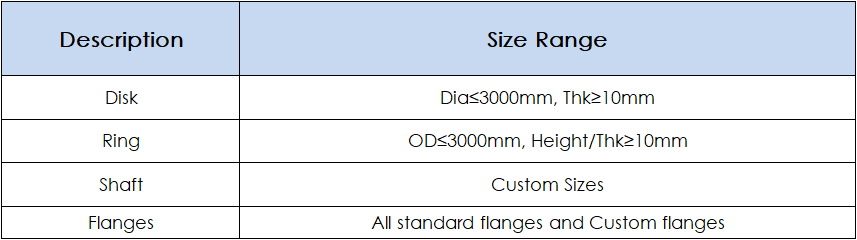

Ibanga losayizi:

Ukwakheka Kwekhemikhali Okutholakalayo

Ukwakheka Kwekhemikhali Okutholakalayo

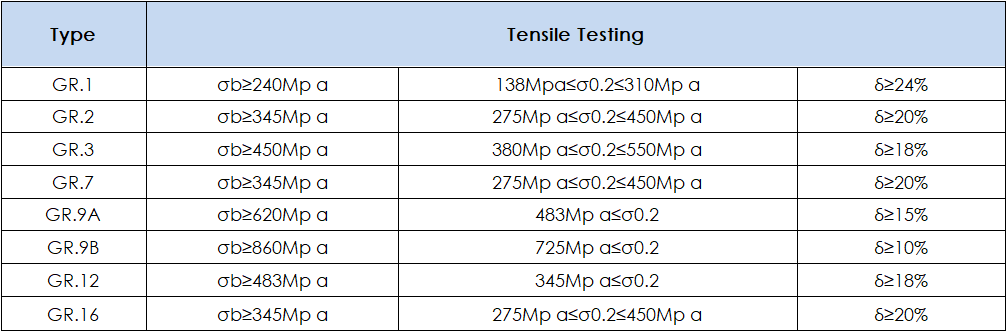

Ukuhlolwa kokuhlola:

- Ukuhlaziywa Kokwakheka Kwamakhemikhali

- Ukuhlolwa Kwempahla Yemishini

- Ukuhlolwa kwe-Tensile

- Ukuhlolwa kwe-Flaring

- Ukuhlola Ukucaba

- Ukugoba Test

- Ukuhlolwa kwe-Hydro-Static

- I-Pneumatic Test (Ukuhlolwa kwengcindezi yomoya ngaphansi kwamanzi)

- Ukuhlolwa kwe-NDT

- Ukuhlolwa Kwamanje kwe-Eddy

- Ukuhlolwa kwe-Ultrasonic

- Ukuhlolwa kwe-LDP

- Ukuhlolwa kwe-Ferroxyl

Ukukhiqiza (Inani Eliphezulu nelincane Le-oda):Unlimited, ngokusho oda.

Isikhathi esiholayo:Isikhathi sokuhola esijwayelekile izinsuku ezingama-30. Nokho, kuya ngenani le-oda ngokufanele.

Ezokuthutha:Indlela evamile yokuhamba ingoLwandle, ngoMoya, nge-Express, ngeSitimela, esizokhethwa ngamakhasimende.

Ukupakisha:

- Ipayipi ligcina livikelwe ngamakepisi epulasitiki noma amakhadibhodi.

- Konke ukufakwa kufanele kupakishwe ukuvikela iziphetho nokubheke.

- Zonke ezinye izimpahla zizopakishwa ngamaphedi amagwebu kanye nokupakishwa kwepulasitiki okuhlobene namakesi e-plywood.

- Noma iziphi izinkuni ezisetshenziselwa ukupakisha kufanele zifaneleke ukuvimbela ukungcola ngokuthintana nemishini yokubamba.