I-Titanium Plate, Ishidi kanye nekhoyili

Inqubo Yokukhiqiza I-Titanium Plate

I-Hot Forging Inqubo yokubumba lapho insimbi iphinda ikristalulwe ngaphezu kwezinga lokushisa.I-Hot Rolling Inqubo yokuginqika emazingeni okushisa angaphezu kwe-recrystallization.Inqubo yokugoqa ebandayo lapho izinga lokushisa lepulasitiki liphansi kunezinga lokushisa lokubuyisela.

I-Annealing: Inqubo lapho izinsimbi zishisisa kancane kumazinga okushisa athile, isikhathi esanele, bese zipholiswa (ngokuvamile kancane futhi ngezinye izikhathi zilawulwa) ngesilinganiso esifanele.

I-Pickling: Gxilisa umkhiqizo kusisombululo esinamanzi, njenge-sulfuric acid, ukuze ususe ama-oxide namanye amafilimu amancane endaweni yensimbi.I-electroplating, koqweqwe lwawo, ukugingqa nezinye izinqubo zokwelashwa kwangaphambili noma ukwelashwa okuphakathi.

Izici ze-titanium plate

1. Ipuleti lembewu ye-Titanium ifilimu ene-oxidized phezulu, elilingana ne-ejenti enhle yokuhlukanisa izinwele engagugi. Ukusetshenziswa kwepuleti lembewu le-titanium kusindisa i-ejenti yokuhlukanisa, kwenza ipuleti lixebuke kalula, kuqede inqubo yokucutshungulwa kusengaphambili kwepuleti lembewu, futhi ipuleti lembewu le-titanium lilula ngohhafu kunepuleti lembewu yethusi.

2. Impilo yesevisi ye-titanium seed plate ingaphezu kokuphindwe ka-3 kune-copper seed plate, engafinyelela eminyakeni eyi-10 kuye kwengama-20 ngokwezimo zokusebenza.

3. Ithusi le-Electrolytic elenziwe ngepuleti lembewu le-titanium linokwakheka kwekristalu elihlangene, indawo ebushelelezi kanye nekhwalithi enhle kakhulu.

4. Ngenxa yokuthi ipuleti le-titanium alidingi ukumbozwa nge-ejenti yokuhlukanisa, lingagwema ukungcoliswa kwe-electrolyte yethusi.

5. Thuthukisa umthamo wokukhiqiza futhi unciphise izindleko zokukhiqiza zethusi le-electrolytic, ukuze kuzuzwe izinzuzo ezingcono zezomnotho.

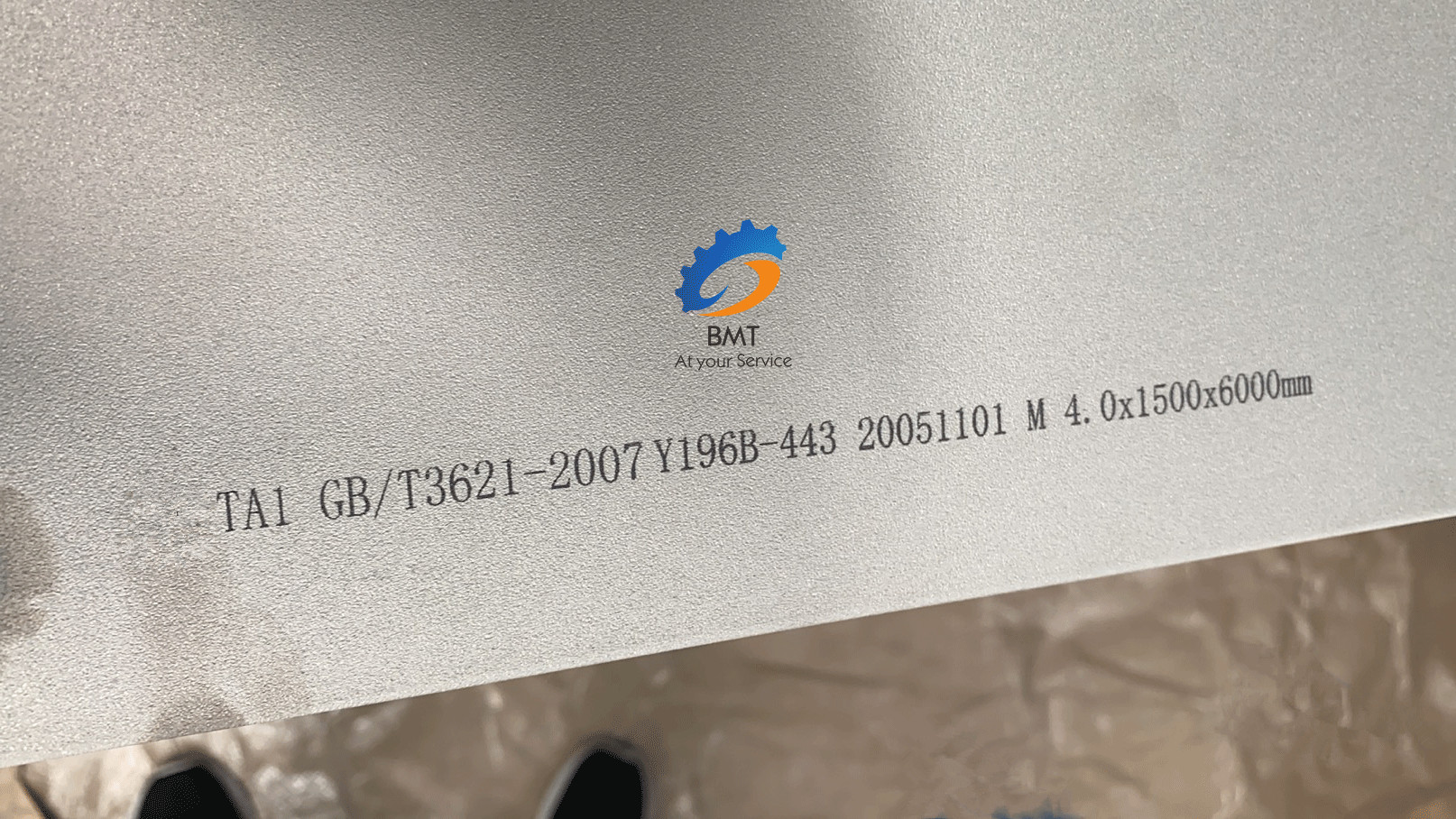

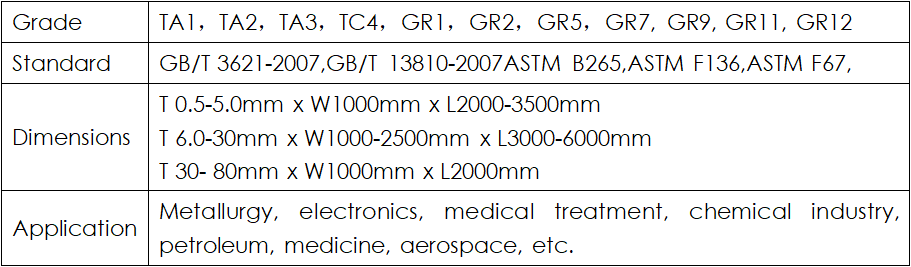

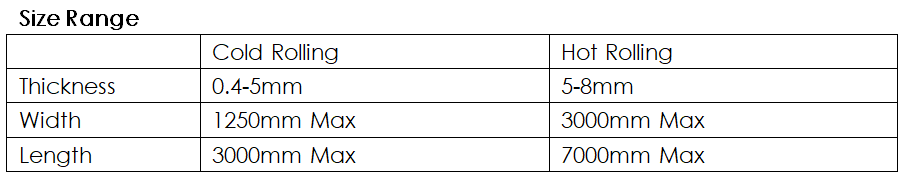

Ibanga le-BMT leshidi nepuleti le-titanium ngokuvamile likhiqizwa ngokuvumelana nezindinganiso ezifana ne-ASTM/ASME B/SB265, ASTM F136, ASTM F67, AMS 4911, kanye ne-AMS4900.

Ukukhiqizwa kwaminyaka yonke kwe-BMT kwamashidi nama-paltes e-titanium ngamathani ayi-10000, okuhlanganisa amathani angu-2000 e-PHE (Iplate yokushisisa), kanye namathani angu-8000 kwezinye izinhlelo zokusebenza. Amashidi namapuleti e-titanium ekhwalithi ephezulu ye-BMT, okuhlanganisa amashidi e-titanium agoqiwe abandayo namapuleti e-titanium aginqiwe ashisayo, alandelelwa ngokuqinile futhi ahlolwe ngokwempahla eluhlaza—isipontshi se-titanium. I-BMT ilawula yonke inqubo, njengokuncibilika, ukubumba, ukuginqika okushisayo, ukugoqa okubandayo, ukwelapha ukushisa, njll. Sithumela imikhiqizo emhlabeni wonke futhi sikwamukela ngokufudumele ukuba usebenzisane nathi.

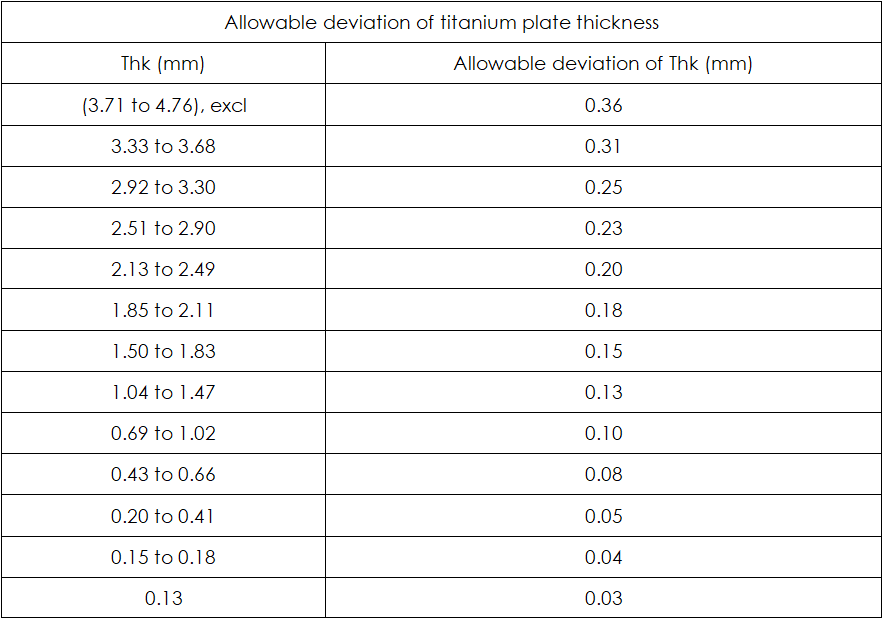

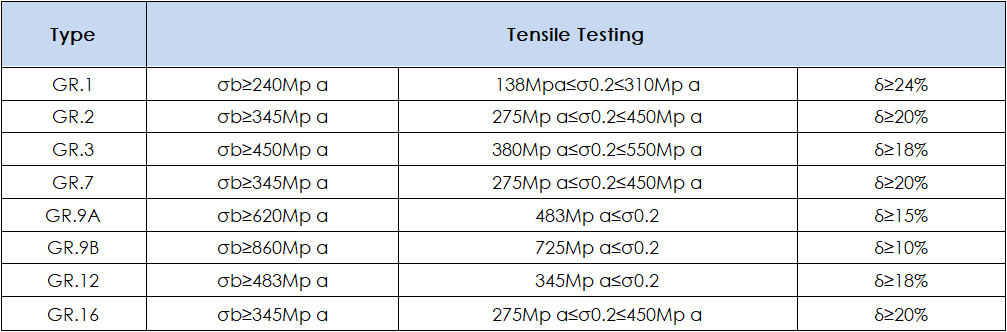

I-Titanium Plate Ukuqina Okuvunyelwe Ukuchezuka:

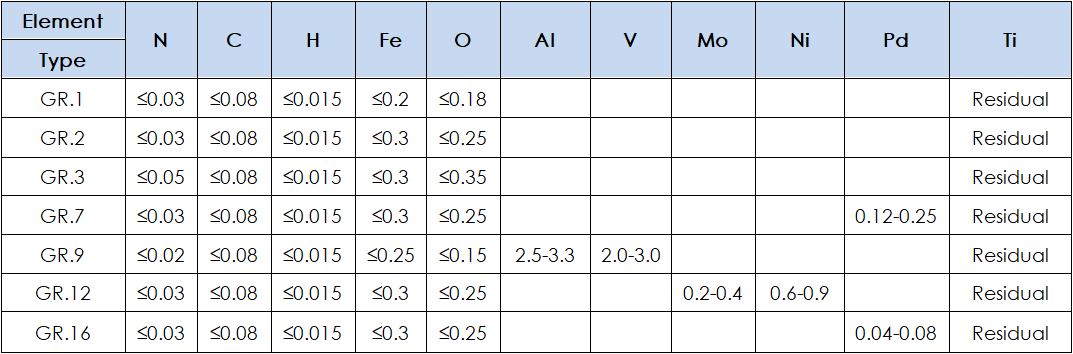

Ukwakheka Kwekhemikhali Okutholakalayo:

Impahla Etholakalayo Yemishini:

Ukuhlolwa kokuhlola:

- Ukuhlaziywa Kokwakheka Kwamakhemikhali

- Ukuhlolwa Kwempahla Yemishini

- Ukuhlolwa kwe-Tensile

- Ukuhlolwa kwe-Flaring

- Ukuhlola Ukucaba

- Ukugoba Test

- Ukuhlolwa kwe-Hydro-Static

- I-Pneumatic Test (Ukuhlolwa kwengcindezi yomoya ngaphansi kwamanzi)

- Ukuhlolwa kwe-NDT

- Ukuhlolwa Kwamanje kwe-Eddy

- Ukuhlolwa kwe-Ultrasonic

- Ukuhlolwa kwe-LDP

- Ukuhlolwa kwe-Ferroxyl

Ukukhiqiza (Inani Eliphezulu nelincane Le-oda):Unlimited, ngokusho oda.

Isikhathi esiholayo:Isikhathi sokuhola esijwayelekile izinsuku ezingama-30. Nokho, kuya ngenani le-oda ngokufanele.

Ezokuthutha:Indlela evamile yokuhamba ingoLwandle, ngoMoya, nge-Express, ngeSitimela, esizokhethwa ngamakhasimende.

Ukupakisha:

- Ipayipi ligcina livikelwe ngamakepisi epulasitiki noma amakhadibhodi.

- Konke ukufakwa kufanele kupakishwe ukuvikela iziphetho nokubheke.

- Zonke ezinye izimpahla zizopakishwa ngamaphedi amagwebu kanye nokupakishwa kwepulasitiki okuhlobene namakesi e-plywood.

- Noma iziphi izinkuni ezisetshenziselwa ukupakisha kufanele zifaneleke ukuvimbela ukungcola ngokuthintana nemishini yokubamba.