I-Titanium Machining Ubunzima

I-thermal conductivity ye-titanium alloy incane, ngakho-ke izinga lokushisa lokusika liphezulu kakhulu lapho kucutshungulwa i-titanium alloy. Ngaphansi kwezimo ezifanayo, izinga lokushisa lokusika lokucubungula i-TC4[i] lingaphezu kokuphindwe kabili kwe-No. 45 steel, futhi ukushisa okukhiqizwa ngesikhathi sokucubungula kunzima ukudlula ku-workpiece. Ukukhululwa; ukushisa okukhethekile kwe-titanium alloy kuncane, futhi izinga lokushisa lendawo likhuphuka ngokushesha ngesikhathi sokucubungula. Ngakho-ke, izinga lokushisa lethuluzi liphezulu kakhulu, ithiphu lethuluzi ligugile kakhulu, futhi impilo yesevisi iyancipha.

I-modulus enwebekayo ephansi ye-titanium alloy[ii] yenza indawo emshinini ithandeke ku-springback, ikakhulukazi ukwenziwa kwezingxenye ezinezindonga ezincane kubucayi kakhulu, okulula ukubangela ukungqubuzana okuqinile phakathi kweflank nendawo ewumshini, ngaleyo ndlela kugqoke ithuluzi futhi ukuqopha. blade.

I-Titanium alloy inomsebenzi wamakhemikhali onamandla, futhi kulula ukuxhumana nomoya-mpilo, i-hydrogen ne-nitrogen ekushiseni okuphezulu, okwandisa amandla ayo futhi kunciphise ipulasitiki yayo. Ungqimba olunothe nge-oksijini olwakheka ngesikhathi sokushisisa nokubunjwa lwenza kube nzima ukwenza imishini.

Izimiso zomshini we-titanium alloy materials[1-3]

Enqubweni yomshini, izinto ezikhethiwe zamathuluzi, izimo zokusika kanye nesikhathi sokusika kuzothinta ukusebenza kahle nomnotho wokusika i-titanium alloy.

1. Khetha ithuluzi elibalulekile

Ngokusho kwezakhiwo, izindlela zokucubungula nokucubungula izimo zobuchwepheshe ze-titanium alloy materials, izinto zamathuluzi kufanele zikhethwe ngokufanele. Impahla yethuluzi kufanele ikhethwe evame ukusetshenziswa kakhulu, intengo ephansi, ukumelana nokugqokwa okuhle, ubulukhuni bokushisa okuphezulu, futhi inokuqina okwanele.

2. Thuthukisa izimo zokusika

Ukuqina kwesistimu yethuluzi lokulungisa umshini kungcono. Ukucaciswa kwengxenye ngayinye yethuluzi lomshini kufanele kulungiswe kahle, futhi ukuphuma kwe-radial kwe-spindle kufanele kube kuncane. Umsebenzi wokuhlanganisa we-fixture kufanele uqine futhi uqine ngokwanele. Ingxenye yokusika yethuluzi kufanele ibe mfushane ngangokunokwenzeka, futhi ubukhulu bomkhawulo wokusika kufanele bukhuliswe ngangokunokwenzeka lapho ukubekezelelana kwe-chip kwanele ukuthuthukisa amandla nokuqina kwethuluzi.

3. Ukwelashwa okushisa okufanelekile kwezinto ezicutshunguliwe

Izakhiwo nesakhiwo se-metallographic sezinto ezisetshenziswayo ze-titanium alloy zishintshwa ukwelashwa kokushisa [iii], ukuze kuthuthukiswe ukusebenza kahle kwezinto.

4. Khetha inani elifanele lokusika

Isivinini sokusika kufanele sibe phansi. Ngenxa yokuthi isivinini sokusika sinethonya elikhulu ekushiseni onqenqemeni lokusika, ukuphakama kwejubane lokusika, ukukhuphuka okubukhali kwezinga lokushisa lomkhawulo wokusika, kanye nezinga lokushisa lomkhawulo wokusika lithinta ngqo impilo yethuluzi, ngakho-ke kuyadingeka ukukhetha ijubane elifanele lokusika.

Thumela umlayezo wakho kithi:

-

Izingxenye ze-Aluminium CNC Machining

-

I-Aluminium Sheet Metal Fabrication

-

I-Axis High Precision CNC Machining Izingxenye

-

Izingxenye Zomshini ze-CNC zase-Italy

-

CNC Machining Aluminium Izingxenye

-

Auto Parts Machining

-

I-Titanium Alloy Forgings

-

I-Titanium ne-Titanium Alloy Fittings

-

I-Titanium ne-Titanium Alloy Forgings

-

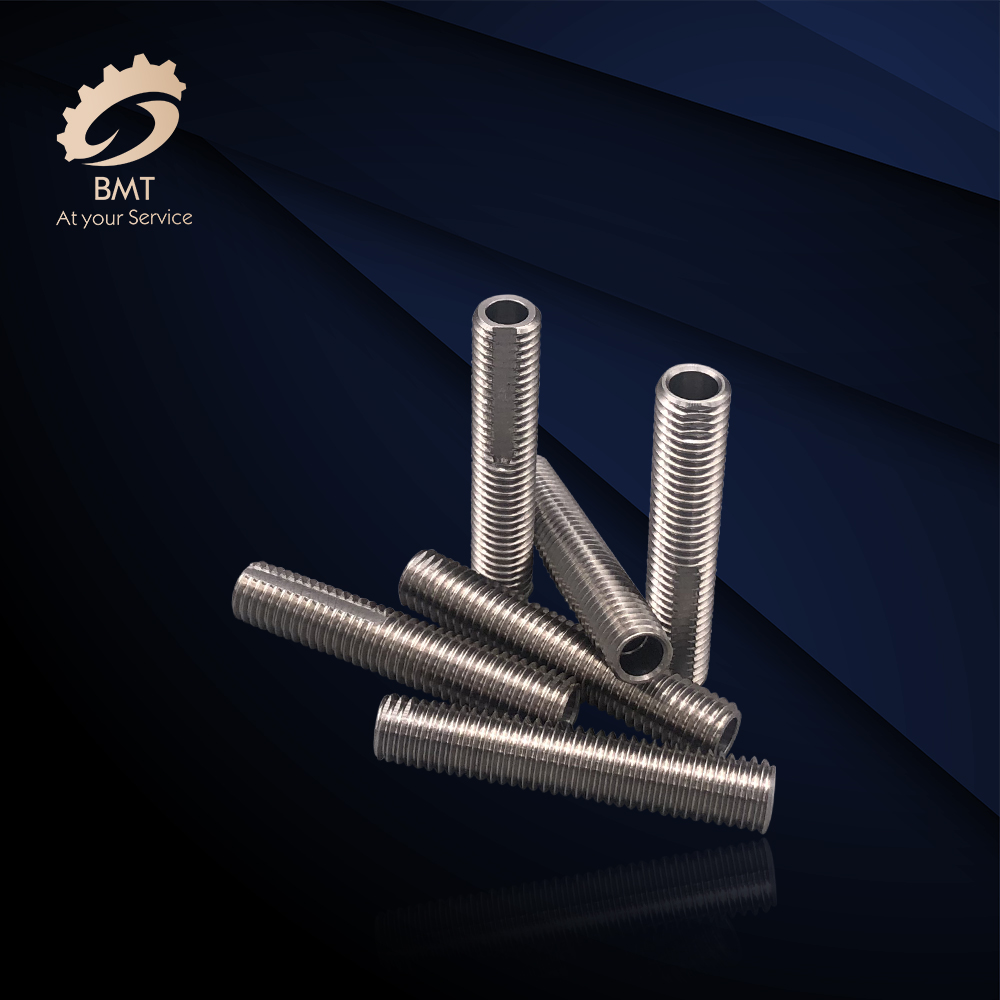

Izintambo ze-Titanium ne-Titanium Alloy

-

Amabha we-Titanium

-

Amapayipi/Amashubhu angenamthungo e-Titanium

-

I-Titanium Welded Pipes/Amashubhu