Izintambo ze-Titanium ne-Titanium Alloy

I-titanium ehlanzekile iyinsimbi emhlophe esiliva, enezici eziningi ezinhle kakhulu. I-Titanium inokuminyana okungu-4.54g/cm3, 43% ilula kunensimbi futhi isinda kancane kune-magnesium yensimbi ekhanyayo ehlonishwayo. Kodwa amandla emishini acishe afane nensimbi, aqine ngokuphindwe kabili kune-aluminium futhi aqine ngokuphindwe kahlanu kune-magnesium. I-Titanium imelana nezinga lokushisa eliphezulu futhi inendawo encibilikayo engu-1942K, cishe ngo-1000K ngaphezu kwegolide futhi icishe ibe ngu-500K ngaphezu kwensimbi.

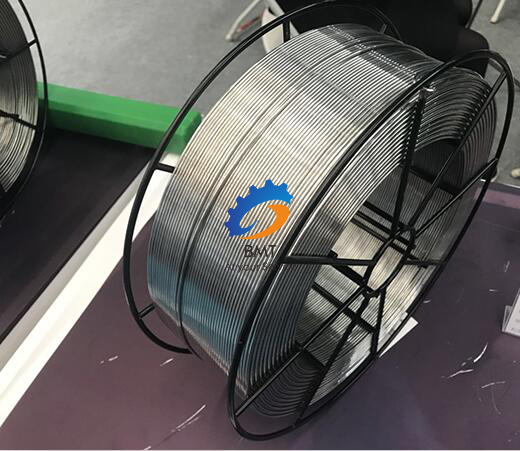

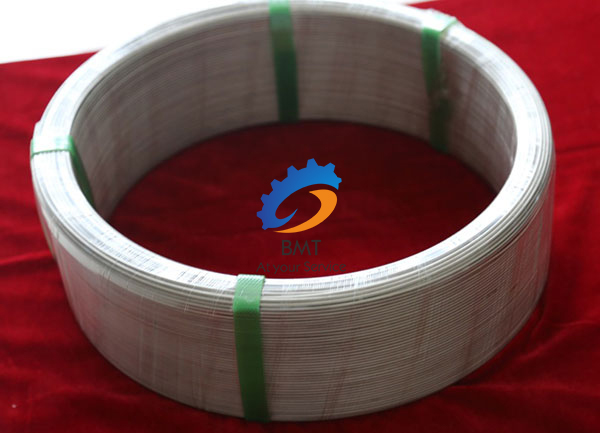

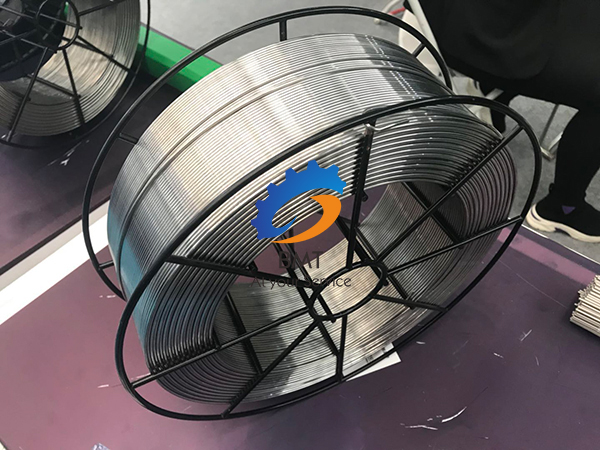

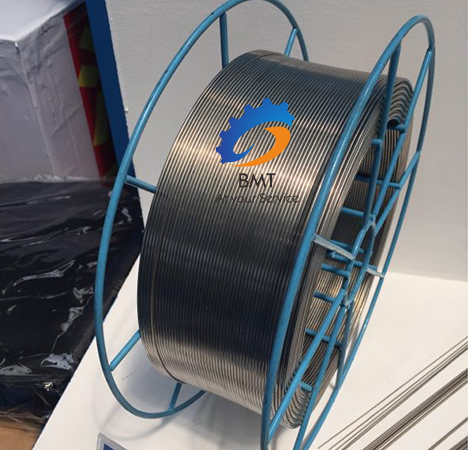

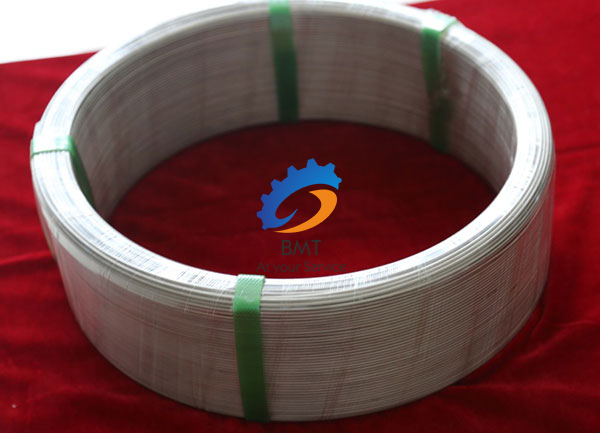

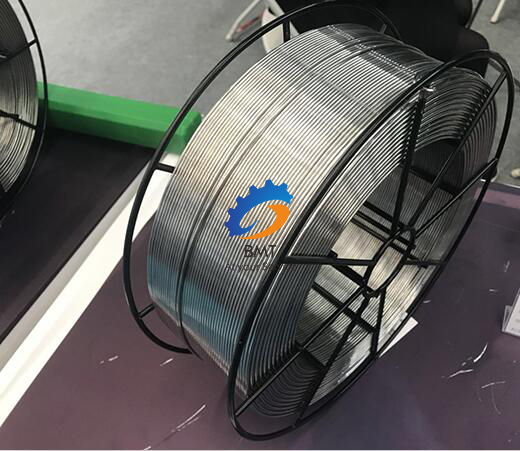

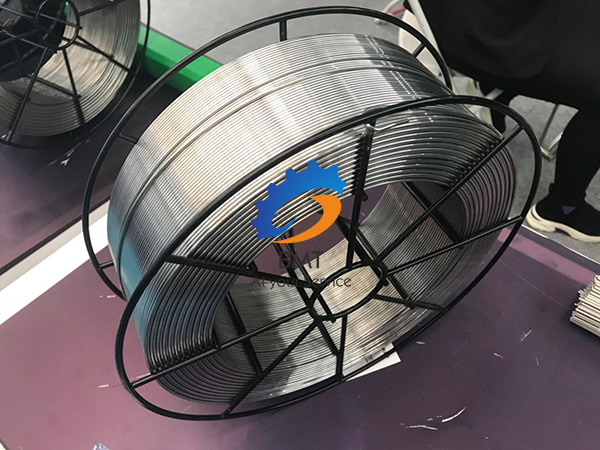

I-Titanium wire ihlukaniswe yaba: i-titanium alloy wire, i-titanium alloy wire, i-titanium eyeglass wire, i-titanium straight wire, i-titanium welding wire, i-titanium welding wire, i-titanium disk wire, i-titanium bright wire, i-titanium yezokwelapha, i-titanium nickel alloy wire. .

I-Titanium Wire Specifications

A. Imininingwane yocingo lwe-Titanium: φ0.8-φ6.0mm

B. Izicaciso zezintambo ze-titanium zezingilazi: φ1.0-φ6.0mm intambo ekhethekile ye-titanium

C. Imininingwane yocingo lwe-Titanium: φ0.2-φ8.0mm ngokulenga okukhethekile

Okujwayelekile:I-GB/T,GJB,AWS,ASTM,AMS,JIS

Ibanga le-Titanium Wire

GR1, GR2, GR3, GR5, GR7, GR9, GR11, GR12, GR16, njll.

Izinkambu Zokusebenza ze-Titanium Wire

Imboni yezempi, ezokwelashwa, izimpahla zezemidlalo, izibuko, amacici, izingubo zasekhanda, ukulengiswa kwe-electroplating, izintambo zokushisela nezinye izimboni.

I-State of Titanium Wire

Isimo se-Annealing (M)

Isimo sokusebenza esishisayo (R)

Isimo sokusebenza esibandayo (Y)

(Annealing, Ultra-Generation Testing)

Ingaphezulu le-Titanium Wire

I-Pickling surface noma indawo ekhanyayo

Intambo ye-Titanium yakha i-carbide ezinzile enobunzima obuphakeme nekhabhoni. Ukukhula kongqimba olune-carbonized phakathi kwe-titanium ne-carbon kunqunywa izinga lokusabalalisa kwe-titanium ongqimbeni lwe-carbonized.

Ukuncibilika kwekhabhoni ku-titanium kuncane, kufinyelela ku-0.3% ku-850X: futhi yehla cishe ku-0.1% ku-600C B Ngenxa yokuncibilika okuphansi kwekhabhoni ku-titanium, ukuqina kwendawo kutholakala kuphela ngongqimba lwe-titanium carbide kanye ne-kimbo yayo. ungqimba ngezansi. Ukungcwatshwa kwe-Carburizing kumele kwenziwe ngaphansi kwesimo sokukhishwa komoyampilo, ngoba ukuqina kongqimba lwangaphezulu lwempushana evame ukusetshenziselwa ukungcwatshwa kwensimbi ebusweni be-carbon monoxide noma i-carbon monoxide equkethe umoya-mpilo kufika ku-2700MPa kanye no-8500MPa, kanye nemeshi. Kulula ukuxebuka.

Ukwakheka Kwekhemikhali Okutholakalayo

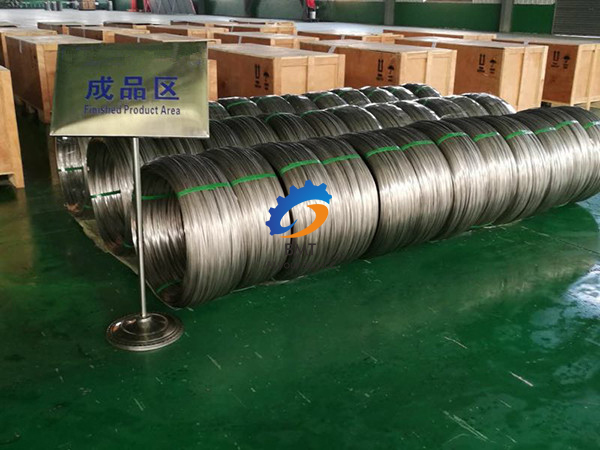

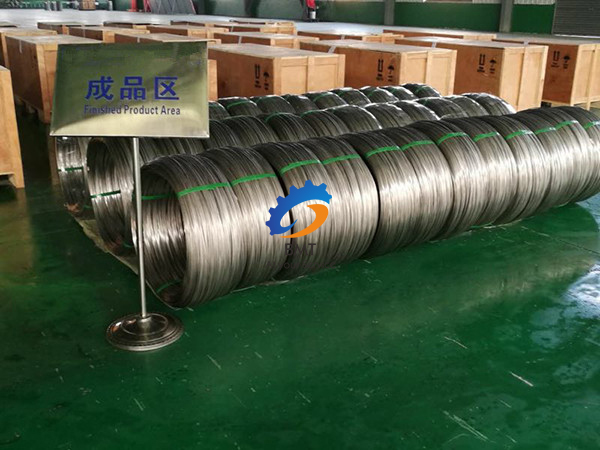

Ukukhiqiza (Inani Eliphezulu nelincane Le-oda):Unlimited, ngokusho oda.

Isikhathi esiholayo:Isikhathi sokuhola esijwayelekile izinsuku ezingama-30. Nokho, kuya ngenani le-oda ngokufanele.

Ezokuthutha:Indlela evamile yokuhamba ingoLwandle, ngoMoya, nge-Express, ngeSitimela, esizokhethwa ngamakhasimende.

Ukupakisha:

- Ipayipi ligcina livikelwe ngamakepisi epulasitiki noma amakhadibhodi.

- Konke ukufakwa kufanele kupakishwe ukuvikela iziphetho nokubheke.

- Zonke ezinye izimpahla zizopakishwa ngamaphedi amagwebu kanye nokupakishwa kwepulasitiki okuhlobene namakesi e-plywood.

- Noma iziphi izinkuni ezisetshenziselwa ukupakisha kufanele zifaneleke ukuvimbela ukungcola ngokuthintana nemishini yokubamba.

.jpg)

Ngokuphambene, ngaphansi kwesimo se-deoxygenation noma i-decarburization, ungqimba oluncane lwe-titanium carbide lungase lwenziwe lapho i-carburized in charcoal. Ukuqina kwalolu ungqimba kungu-32OUOMpa, okuhambisana nobulukhuni be-titanium carbide. Ukujula kongqimba lwe-carburizing ngokuvamile kukhulu kunokwendlalelo ye-nitriding lapho i-nitriding isetshenziswa ngaphansi kwezimo ezifanayo. Ngaphansi kwesimo sokunothisa komoyampilo, umphumela wokumuncwa komoyampilo ekujuleni kokuqina kufanele kucatshangelwe. Kungaphansi kwesimo sokujiya kongqimba oluncane kakhulu lapho amandla anele okunamathela angakhiwa ngokufaka i-carbon powder endaweni engenalutho noma emkhathini we-argon-methane. Ngokuphambene, ukusetshenziswa kwe-agent ye-gas carburizing kungase kwakheke ungqimba oluqinile lwe-titanium carbide oluqinile futhi oluboshwe kahle. Ngesikhathi esifanayo, ukusabalala kokuqina kwakha ezingeni lokushisa phakathi kuka-950T: no-10201:. Ngokukhula kogqinsi lwesendlalelo, ungqimba lwe-TiC luba brittle futhi luvame ukuphephuka. Ukuze ugweme ukugxambukela kwekhabhoni efakwa ongqimbeni lwe-TiC ngenxa yokubola kwe-Reane, ukungcwatshwa kwegesi kufanele kwenziwe ngegesi engasebenzi enesengezo somthamo esinqunyiwe esingaba ngu-2% weReane. Ukuqina kobuso obuphansi kutholakala lapho i-methane ifakwa izithasiselo ze-propane. Uma amandla okubopha afinyelela ku-OKPA futhi i-gas carburized propane isetshenziswa, nakuba ubukhulu bongqimba obuqinile obulinganisiwe buncane kakhulu, bunokumelana okungcono kakhulu kokugqoka. I-hydrogen imuncwa i-gas carburizing ejenti, kodwa kufanele iphinde ikhishwe ngesikhathi sokudonsa i-vacuum annealing.