I-Titanium Alloy CNC Machining

Uma ubulukhuni be-titanium alloy bungaphezu kwe-HB350, ukusika kunzima kakhulu, futhi uma kungaphansi kwe-HB300, kulula ukunamathela kummese futhi kunzima ukusika. Ngakho-ke, inkinga yokucubungula i-titanium ingaxazululwa kusuka ku-blade. Ukuguga komsele wokufaka emishinini yama-alloys e-titanium wukugqokwa kwendawo ngemuva nangaphambili maqondana nokujula kokusikwa, okuvame ukubangelwa ungqimba oluqinile olushiywe umshini wangaphambilini.

Ukusabela kwamakhemikhali kanye nokusabalalisa kwethuluzi kanye nezinto zokusebenza endaweni yokushisa yokucubungula engaphezu kuka-800 °C nakho kungesinye sezizathu zokwakheka kokugqoka kwe-groove. Ngoba ngesikhathi senqubo yomshini, ama-molecule e-titanium we-workpiece aqoqana phambi kwe-blade futhi "ahlanganiswe" emaphethelweni e-blade ngaphansi kwengcindezi ephakeme kanye nokushisa okuphezulu, okwenza unqenqema olwakhiwe.

Lapho unqenqema olwakhiwe lucweba onqenqemeni lokusika, lususa uqweqwe lwe-carbide lokufaka, ngakho-ke umshini we-titanium udinga izinto zokufaka ezikhethekile kanye namajiometri.

.

Kuhle ukusho ukuthi njengoba ama-titanium alloys ekhiqiza ukushisa okuphezulu ngesikhathi sokucutshungulwa, inani elikhulu le-high-pressure cutting fluid kufanele lifafazwe onqenqemeni lokusika ngesikhathi nangendlela enembile ukuze kukhishwe ukushisa ngokushesha. Kukhona nezakhiwo ezihlukile zabasiki bokugaya ezisetshenziselwa ngokukhethekile ukucubungula i-titanium alloy emakethe namuhla, ezifanele kangcono ukucutshungulwa kwe-titanium alloy.

Njengamanje, wonke amazwe athuthukisa ama-alloys amasha e-titanium anezindleko eziphansi nokusebenza okuphezulu, futhi alwela ukwenza ama-titanium alloys angene emkhakheni wezimboni wezakhamuzi onamandla amakhulu emakethe. izwe lami nalo aliyigodli imizamo yokuqhubekela phambili kulo mkhakha.

Kukholakala ukuthi ngemizamo ehlanganyelwe yabo bonke ochwepheshe bezimboni, ukucutshungulwa kwezingxubevange ze-titanium ngeke kusaba yinkinga esikhathini esizayo, kodwa kuzoba yinsephe ebukhali ekuthuthukiseni imboni yezokukhiqiza yezwe lami, kunqobe izithiyo zokuthuthukiswa kwemboni yezokukhiqiza. yonke imboni.

Thumela umlayezo wakho kithi:

-

Izingxenye ze-Aluminium CNC Machining

-

I-Aluminium Sheet Metal Fabrication

-

I-Axis High Precision CNC Machining Izingxenye

-

Izingxenye Zomshini ze-CNC zase-Italy

-

CNC Machining Aluminium Izingxenye

-

Auto Parts Machining

-

I-Titanium Alloy Forgings

-

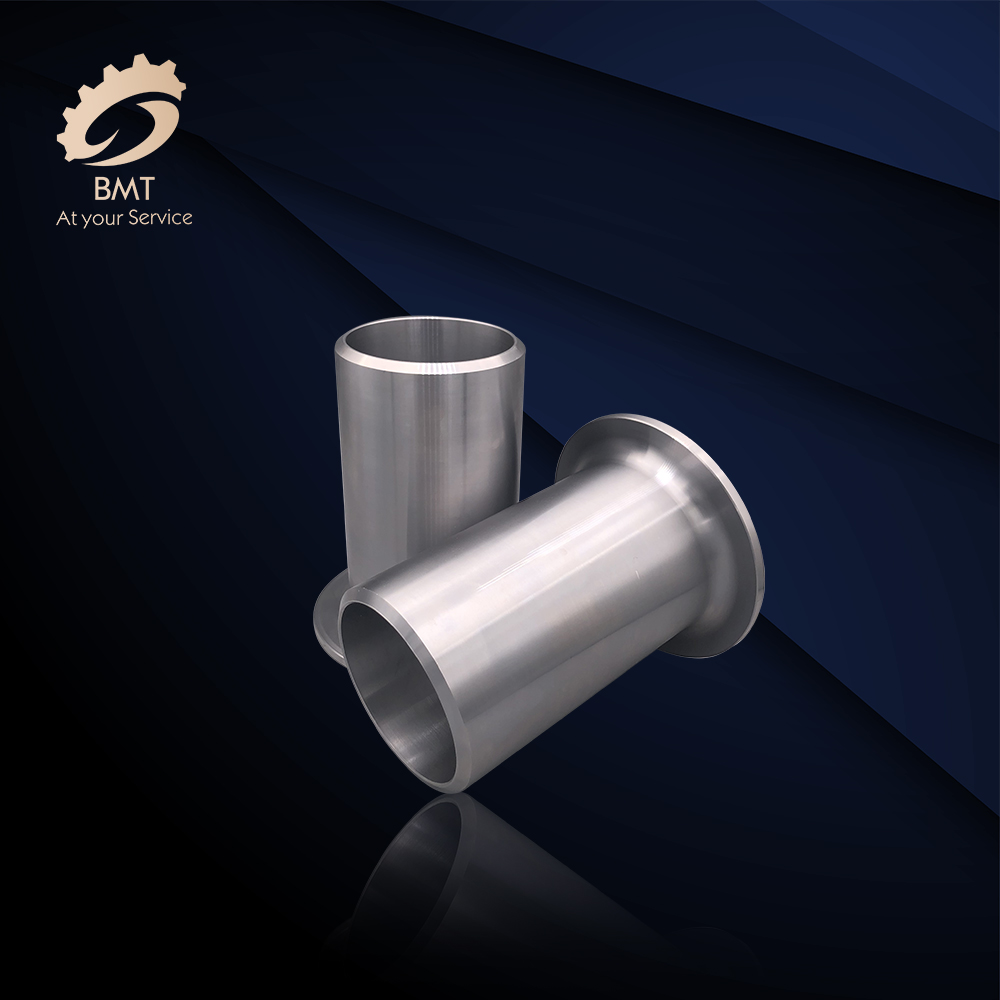

I-Titanium ne-Titanium Alloy Fittings

-

I-Titanium ne-Titanium Alloy Forgings

-

Izintambo ze-Titanium ne-Titanium Alloy

-

Amabha we-Titanium

-

Amapayipi/Amashubhu angenamthungo e-Titanium

-

I-Titanium Welded Pipes/Amashubhu