I-Titanium Machining Ubunzima

(1) I-deformation coefficient incane:

Lesi yisici esisobala kakhulu ekwenziweni kwe-titanium alloy materials. Ngesikhathi sokusika, indawo yokuxhumana phakathi kwe-chip nobuso be-rake inkulu kakhulu, futhi ukushaywa kwe-chip ebusweni be-rake yethuluzi kukhulu kakhulu kunokwempahla evamile. Ukuhamba okunjalo kwesikhathi eside kuzodala ukugqoka kwamathuluzi angathi sína, futhi i-Friction iphinde yenzeke ngesikhathi sokuhamba, okwandisa izinga lokushisa kwethuluzi.

(2) Izinga lokushisa eliphezulu lokusika:

Ngakolunye uhlangothi, i-deformation coefficient encane okukhulunywe ngayo ngenhla izoholela engxenyeni yokwanda kwezinga lokushisa. Isici esiyinhloko sokushisa okuphezulu kokusika kwinqubo yokusika i-titanium alloy ukuthi ukuqhutshwa kokushisa kwe-titanium alloy kuncane kakhulu, futhi ubude bokuxhumana phakathi kwe-chip kanye ne-rake face yethuluzi bufushane.

Ngaphansi kwethonya lalezi zici, ukushisa okukhiqizwa phakathi nenqubo yokusika Kunzima ukuyidlulisela ngaphandle, futhi ikakhulukazi iqoqa eduze nesihloko sethuluzi, okwenza izinga lokushisa lendawo libe phezulu kakhulu.

(3) I-thermal conductivity ye-titanium alloy iphansi kakhulu:

Ukushisa okukhiqizwa ngokusika akuqedwa kalula. Inqubo yokuguqula i-titanium alloy iyinqubo yokucindezeleka okukhulu nokucindezeleka okukhulu, okuzokhiqiza ukushisa okukhulu, futhi ukushisa okuphezulu okukhiqizwa ngesikhathi sokucubungula akukwazi ukusakazeka ngokuphumelelayo. Ku-blade, izinga lokushisa likhuphuka kakhulu, i-blade iyathamba, futhi ukugqoka kwamathuluzi kuyashesha.

Amandla athile emikhiqizo ye-titanium alloy aphezulu kakhulu phakathi kwezinto zokwakha zensimbi. Amandla ayo afana nensimbi, kodwa isisindo sayo singama-57% kuphela wensimbi. Ngaphezu kwalokho, ama-alloys e-titanium anezici zamandla adonsela phansi amancane athile, amandla aphezulu okushisa, ukuzinza okuhle kokushisa nokumelana nokugqwala, kodwa izinto zokwakha ze-titanium alloy zinzima ukuzisika futhi zisebenza kahle kakhulu. Ngakho-ke, indlela yokunqoba ubunzima nokusebenza kahle okuphansi kokucutshungulwa kwe-titanium alloy bekulokhu kuyinkinga ephuthumayo okufanele ixazululwe.

Thumela umlayezo wakho kithi:

-

Izingxenye ze-Aluminium CNC Machining

-

I-Aluminium Sheet Metal Fabrication

-

I-Axis High Precision CNC Machining Izingxenye

-

Izingxenye Zomshini ze-CNC zase-Italy

-

CNC Machining Aluminium Izingxenye

-

Auto Parts Machining

-

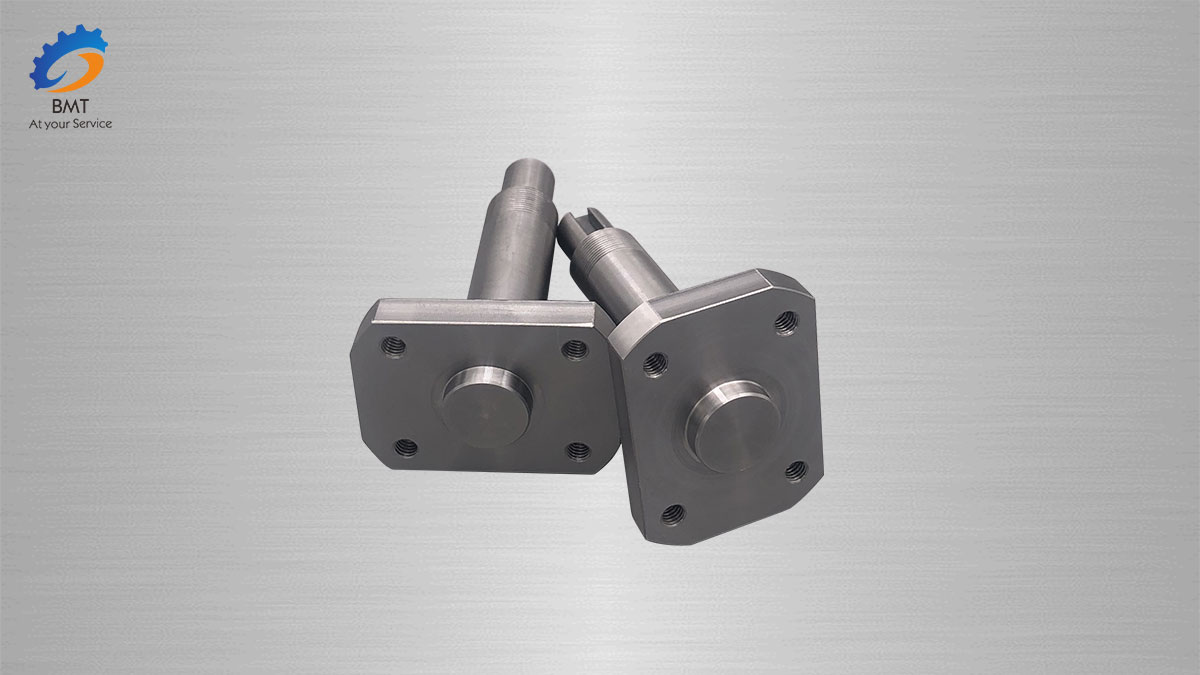

I-Titanium Alloy Forgings

-

I-Titanium ne-Titanium Alloy Fittings

-

I-Titanium ne-Titanium Alloy Forgings

-

Izintambo ze-Titanium ne-Titanium Alloy

-

Amabha we-Titanium

-

Amapayipi/Amashubhu angenamthungo e-Titanium

-

I-Titanium Welded Pipes/Amashubhu