Mechanical Machining Izinhlobo

Ukuhlukaniswa Okuyinhloko

Kunezinhlobo ezimbili eziyinhloko zemishini: ukwenza ngesandla kanye ne-CNC machining. Ukucubungula ngesandla kubhekisela endleleni yokucubungula izinto ezihlukahlukene ngokusebenza ngesandla kwemishini yemishini efana nemishini yokugaya, ama-lathes, imishini yokumba kanye nemishini yokusaha ngabasebenzi bemishini. Ukwenza imanuwali kulungele ivolumu ephansi, ukukhiqizwa kwengxenye elula. I-CNC machining (CNC) ibhekisela ekusetshenzisweni kwemishini ye-CNC ngabasebenzi abayimishini ukuze bacutshungulwe. Le mishini ye-CNC ihlanganisa izikhungo zemishini, izikhungo zokuguqula nokugaya, imishini ye-EDM yocingo, imishini yokusika intambo, njll. Iningi lezitolo zemishini zisebenzisa ubuchwepheshe bemishini ye-CNC. Ngokuhlela, izixhumanisi zezikhundla (X, Y, Z) zocezu lokusebenza ohlelweni lwe-Cartesian coordinate ziguqulwa zibe ulimi lokuhlela.

Isilawuli se-CNC sethuluzi lomshini we-CNC silawula i-eksisi yethuluzi lomshini we-CNC ngokuhlonza nokutolika ulimi lokuhlela, futhi ngokuzenzakalelayo sisusa izinto ezidingekayo. , ukuze uthole umsebenzi oqediwe. I-CNC machining icubungula ama-workpieces ngendlela eqhubekayo futhi ifanele inani elikhulu lezingxenye ezinobumo obuyinkimbinkimbi.

Ukucubungula Ubuchwepheshe

Indawo yokusebenzela yomshini ingasebenzisa uhlelo lwe-CAD/CAM (Computer Aided Design Computer Aided Manufacturing) ukuhlela ngokuzenzakalelayo amathuluzi omshini we-CNC. I-geometry yengxenye idluliswa ngokuzenzakalelayo isuka ohlelweni lwe-CAD iye ohlelweni lwe-CAM, futhi umakhi wemishini ukhetha izindlela ezihlukahlukene zomshini ekuboniseni okubonakalayo. Lapho umakhi wemishini ekhetha indlela ethile yokwenza imishini, isistimu ye-CAD/CAM ingakhipha ngokuzenzakalelayo ikhodi ye-CNC, ngokuvamile ebizwa ngokuthi ikhodi ye-G, futhi ifake ikhodi kusilawuli sethuluzi lomshini we-CNC ukuze kwenziwe imisebenzi yomshini yangempela.

Ezinye Izisetshenziswa

Imishini engemuva kwefekthri, njengamathuluzi omshini wokusika insimbi (okuhlanganisa ukuphenduka, ukugaya, ukuhlela, ukufaka kanye nezinye izinto zokusebenza), uma izingxenye zemishini edingekayo ekukhiqizeni ziphukile futhi zidinga ukulungiswa, zidinga ukuthunyelwa emashini. indawo yokusebenzela yokulungisa noma yokucubungula. Ukuze kuqinisekiswe inqubekelaphambili eshelelayo yokukhiqiza, amabhizinisi ajwayelekile anemihlangano yokucobelelana ngolwazi yemishini, okuyiwona abhekene kakhulu nokugcinwa kwemishini yokukhiqiza.

Izinqubo Zokusebenza

I. Uhlolojikelele

Le nqubo yokusebenza yenza imiyalelo eqondile neningiliziwe yabo bonke opharetha abenza imishini ukuze baqinisekise ikhwalithi yengxenye ngayinye eyenziwe ngomshini.

2. Ububanzi besicelo

Lo mthethonqubo ucacisa imisebenzi ethile yabasebenzi abasebenza ngomshini (okuhlanganisa ukujika, ukugaya, ukubhola, ukuhlela, ukugaya, ukugunda, njll.) ngesikhathi somsebenzi.

3. Imithetho ejwayelekile

Ukucutshungulwa kwemishini kufanele kwenziwe ngokuhambisana nalo mthethonqubo ngesikhathi sokucutshungulwa kwezingxenye ezihlukahlukene zomshini.

Thumela umlayezo wakho kithi:

-

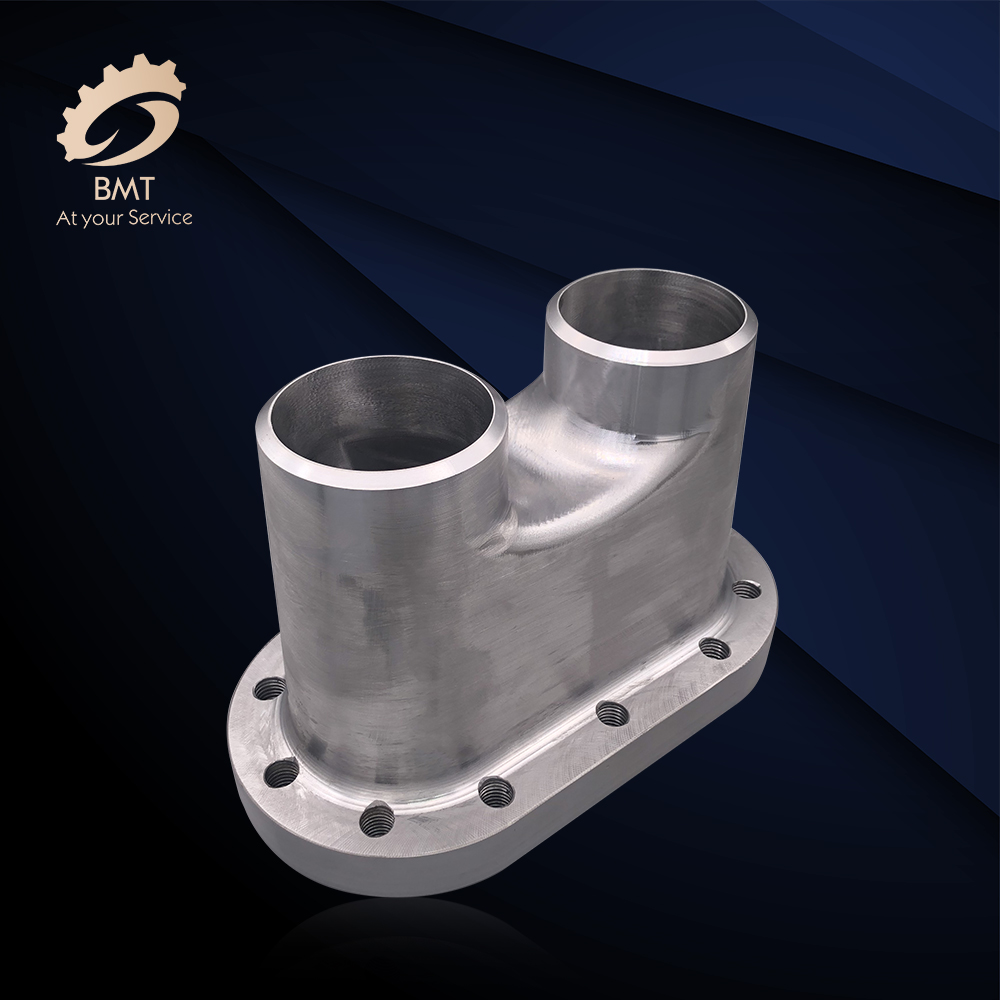

Izingxenye ze-Aluminium CNC Machining

-

I-Aluminium Sheet Metal Fabrication

-

I-Axis High Precision CNC Machining Izingxenye

-

Izingxenye Zomshini ze-CNC zase-Italy

-

CNC Machining Aluminium Izingxenye

-

Auto Parts Machining

-

I-Titanium Alloy Forgings

-

I-Titanium ne-Titanium Alloy Fittings

-

I-Titanium ne-Titanium Alloy Forgings

-

Izintambo ze-Titanium ne-Titanium Alloy

-

Amabha we-Titanium

-

Amapayipi/Amashubhu angenamthungo e-Titanium

-

I-Titanium Welded Pipes/Amashubhu