Ukukhetha Amathuluzi CNC Machining

Umgomo Wokukhetha Amathuluzi e-CNC

Impilo yamathuluzi ihlobene eduze nokusika ivolumu. Lapho wenza amapharamitha okusika, impilo yamathuluzi enengqondo kufanele ikhethwe kuqala, futhi impilo yamathuluzi enengqondo kufanele inqunywe ngokuya ngomgomo wokuthuthukisa. Ngokuvamile ihlukaniswa ngempilo yamathuluzi okukhiqiza ephezulu kakhulu kanye nempilo yamathuluzi enezindleko eziphansi kakhulu, eyokuqala inqunywa ngokomgomo wamahora omuntu ocezu olulodwa oluncane, futhi lokhu kwakamuva kunqunywa ngokuvumelana nomgomo wezindleko zenqubo eziphansi kakhulu.

Lapho ukhetha amathuluzi, ungacabangela amaphuzu alandelayo ngokusho kobunzima bethuluzi, izindleko zokukhiqiza nokugaya. Impilo yamathuluzi ayinkimbinkimbi futhi anembe kakhulu kufanele ibe phezulu kunaleyo yamathuluzi anomkhawulo owodwa. Ngamathuluzi ezinkomba ze-clamp clamp, ngenxa yesikhathi esifushane sokushintsha ithuluzi, ukuze unikeze ukudlala okugcwele ekusebenzeni kwayo kokusika futhi kuthuthukiswe ukusebenza kahle kokukhiqiza, impilo yamathuluzi ingakhethwa ukuthi ibe ngaphansi, ngokuvamile i-15-30min. Ngamathuluzi amaningi, amathuluzi omshini we-modular namathuluzi okwenza imishini azenzakalelayo anokufakwa kwamathuluzi ayinkimbinkimbi, ukuguqulwa kwamathuluzi, nokulungiswa kwamathuluzi, impilo yamathuluzi kufanele ibe phezulu, futhi ukwethembeka kwethuluzi kufanele kuqinisekiswe ikakhulukazi.

Lapho ukukhiqizwa kwenqubo ethile ku-workshop kunciphisa ukuthuthukiswa kokukhiqiza kwe-workshop yonke, impilo yamathuluzi yenqubo kufanele ikhethwe ibe phansi. Uma izindleko zesitshalo sonke ngesikhathi seyunithi yenqubo ethile zinkulu ngokuqhathaniswa, impilo yamathuluzi kufanele futhi ikhethwe Phansi. Lapho uqeda izingxenye ezinkulu, ukuze kuqinisekiswe ukuthi okungenani ukudlula okukodwa kuqediwe, futhi ukugwema ukushintsha ithuluzi phakathi kokusika, impilo yamathuluzi kufanele inqunywe ngokuvumelana nokunemba kwengxenye kanye nobukhulu obungaphezulu. Uma kuqhathaniswa nezindlela ezijwayelekile zokucubungula ithuluzi lomshini, umshini we-CNC ubeka phambili izidingo eziphakeme kumathuluzi okusika.

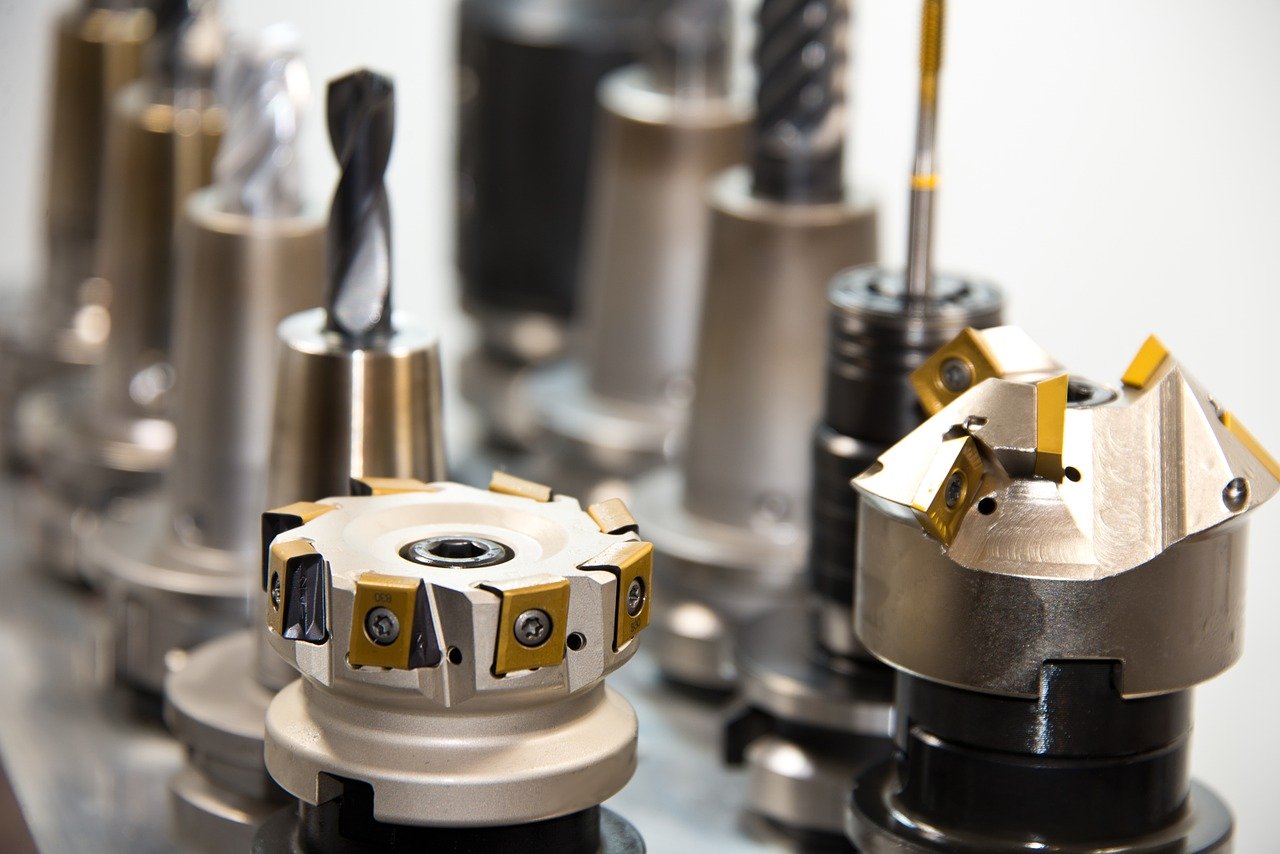

Akudingi nje kuphela ikhwalithi enhle nokunemba okuphezulu, kodwa futhi kudinga ukuzinza kwe-dimensional, ukuqina okuphezulu, nokufakwa kalula nokulungiswa. Hlangana nezidingo ezisebenza kahle kakhulu zamathuluzi omshini we-CNC. Amathuluzi akhethiwe kumathuluzi omshini we-CNC ngokuvamile asebenzisa izinto zamathuluzi ezifanele ukusika ngesivinini esikhulu (njengensimbi enesivinini esikhulu, i-ultra-fine-grained cemented carbide) kanye nokusebenzisa okufakwayo okunenkomba.

Khetha Amathuluzi Okuguqula I-CNC

Amathuluzi okuguqula i-CNC asetshenziswa kakhulu ahlukaniswe abe izinhlobo ezintathu: amathuluzi okwakha, amathuluzi acijile, amathuluzi e-arc nezinhlobo ezintathu. Amathuluzi okuguqula okwakha abizwa nangokuthi amathuluzi okuguqula i-prototype, futhi umumo wekhonta wezingxenye eziwumshini unqunywa ngokuphelele ukuma nosayizi wonqenqema lokusika wethuluzi lokujika. Ekucubunguleni i-CNC, amathuluzi okuguqula ajwayelekile ahlanganisa amathuluzi okujika erediyasi encane, amathuluzi okujika angewona awonxande namathuluzi okuhlanganisa. Emashini ye-CNC, ithuluzi lokuphendula kufanele lisetshenziswe kancane ngangokunokwenzeka noma cha. Ithuluzi lokuguqula elikhonjiwe liyithuluzi lokuguqula elibonakala ngokusika okuqondile.

Ithiphu yalolu hlobo lwethuluzi lokujika lakhiwe imiphetho eqondile eyinhloko neyesibili yokusika, njengamathuluzi okujika angama-900 angaphakathi nangaphandle, amathuluzi okuguqula ubuso kwesokunxele nakwesokudla, amathuluzi okujika ama-grooving (akusike), kanye nemiphetho ehlukahlukene yokusika yangaphandle neyangaphakathi ama-tip chamfers amancane. Ithuluzi lokuvula imbobo. Indlela yokukhetha yamapharamitha wejiyomethri wethuluzi lokujika elicijile (ikakhulukazi i-engeli yejometri) ngokuyisisekelo iyafana naleyo yokujika okuvamile, kodwa izici zomshini we-CNC (njengomzila womshini, ukuphazamiseka kwemishini, njll.) kufanele zicatshangelwe ngokugcwele. , futhi ithiphu lamathuluzi ngokwalo kufanele libhekwe njengamandla.

Okwesibili ithuluzi lokujika elimise okwe-arc. Ithuluzi lokujika elimise okwe-arc liyithuluzi elijikayo elibonakala ngomphetho wokusika omise okwe-arc onephutha elincane eliyindingilizi noma lephrofayela yomugqa. Iphuzu ngalinye lonqenqema lwe-arc lwethuluzi lokujika liyiphuzu lethuluzi lokujika elimise okwe-arc. Ngakho-ke, iphoyinti lokumisa ithuluzi alikho ku-arc, kodwa maphakathi ne-arc. Ithuluzi lokujika elimise okwe-arc lingasetshenziselwa ukuguqula izindawo zangaphakathi nezingaphandle, futhi lifaneleka ngokukhethekile ukuguqula izindawo ezakhayo ezixhumeke kahle (concave). Lapho kukhethwa i-arc radius yethuluzi lokujika, kufanele kucatshangelwe ukuthi i-arc radius yonqenqema lokusika lwethuluzi lokujika lamaphoyinti amabili kufanele ibe ngaphansi noma ilingane nerediyasi encane yokugoba ku-concave yengxenye, ukuze ukugwema ukucubungula ukoma. Irediyasi akufanele ikhethwe incane kakhulu, ngaphandle kwalokho ngeke kube nzima nje ukuyikhiqiza, Ithuluzi lokuguqula lingase lonakaliswe ngenxa yamandla wethiphu yethuluzi elibuthakathaka noma amandla ampofu okukhipha ukushisa komzimba wethuluzi.