Amakhono Okukhetha Amathuluzi we-CNC Machining

Khetha Amathuluzi e-CNC Milling

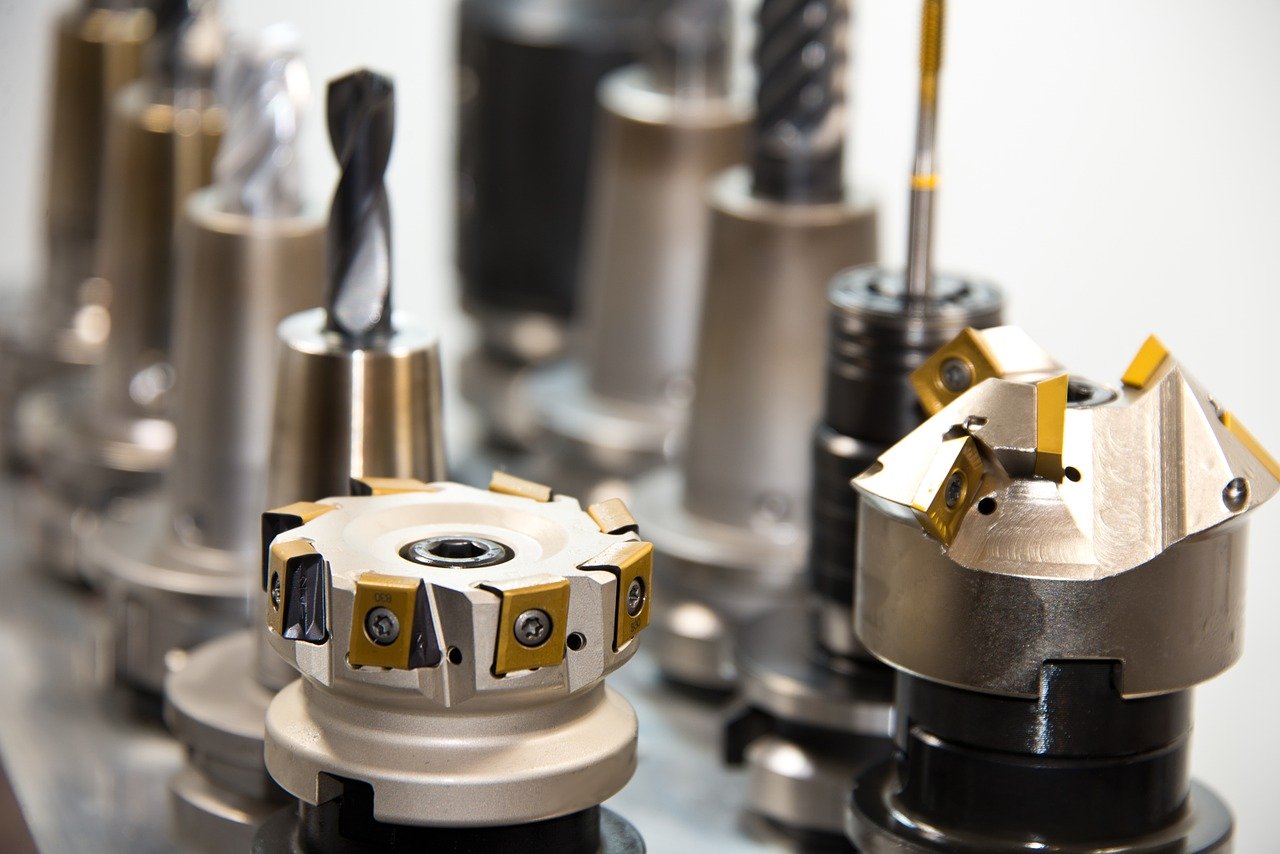

Emishinini ye-CNC, izigayo eziphansi eziphansi zivame ukusetshenziselwa ukugaya amakhonco angaphakathi nangaphandle ezingxenye zendiza kanye nendiza yokugaya. Idatha yobufakazi yamapharamitha afanelekile wethuluzi imi kanje: Okokuqala, irediyasi yesisiki sokugaya kufanele ibe ncane kunerediyasi encane ye-curvature Rmin yendawo engaphakathi yekhonta yengxenye, ngokuvamile i-RD= (0.8-0.9) Rmin . Okwesibili ukuphakama kokucubungula kwengxenye H< (1/4-1/6) RD ukuze kuqinisekiswe ukuthi ummese unokuqina okwanele. Okwesithathu, lapho kugaywa phansi inkatho engaphakathi ngomshini wokugaya ophansi ophansi, ngoba amaphasi amabili enkaba ephansi adinga ukwedlula, futhi irediyasi yonqenqema olungezansi lwethuluzi ithi Re=Rr, okungukuthi, ububanzi bungu-d=2Re=2(Rr), lapho kuhlelwa Thatha irediyasi yethuluzi njengeRe=0.95 (Rr).

Ukuze kucutshungulwe amanye amaphrofayili anezinhlangothi ezintathu kanye namakhonta anama-engeli aguquguqukayo we-bevel, izisiki zokugaya eziyindilinga, izisiki zokugaya indandatho, izisiki zokugaya izigubhu, izisiki zokugaya ezinama-tapered kanye nabasiki be-disc milling zivame ukusetshenziswa. Njengamanje, iningi lamathuluzi omshini we-CNC asebenzisa amathuluzi ajwayelekile futhi ajwayelekile. Kunamazinga kazwelonke kanye namamodeli ahleliwe wabaphethe amathuluzi nezinhloko zamathuluzi njengamathuluzi okujika angaphandle aboshwe ngomshini namathuluzi okuguqula ubuso. Okwezikhungo zemishini kanye nezishintshi zamathuluzi ezizenzakalelayo Amathuluzi omshini afakiwe kanye nezibambi zamathuluzi asenziwe ama-serial futhi asezingeni. Isibonelo, ikhodi evamile yesistimu yamathuluzi e-tapered shank yi-TSG-JT, futhi ikhodi evamile yesistimu yamathuluzi e-shank eqondile yi-DSG-JZ. Ngaphezu kwalokho, ngethuluzi elikhethiwe Ngaphambi kokusetshenziswa, kuyadingeka ukukala usayizi wethuluzi ngokuqinile ukuze uthole idatha enembile, futhi opharetha uzofaka le datha ohlelweni lwedatha, futhi aqedele inqubo yokucubungula ngocingo lohlelo, ngaleyo ndlela acubungule ama-workpieces afanelekayo. .

Iphuzu Lethuluzi Lokugoqa kanye Nephuzu Lokushintsha Ithuluzi

Ithuluzi liqala ukusuka kusiphi isikhundla ukuya endaweni ethile? Ngakho-ke ekuqaleni kokwenziwa kohlelo, indawo lapho ithuluzi liqala ukuhamba khona ohlelweni lokuxhumanisa i-workpiece kufanele kunqunywe. Lesi sikhundla siyindawo yokuqala yethuluzi elihlobene nendawo yokusebenza lapho uhlelo lwenziwa. Ngakho-ke kubizwa ngokuthi iphoyinti lokuqala lohlelo noma indawo yokuqala. Leli phuzu lokuqala livame ukunqunywa ukulungiselelwa kwamathuluzi, ngakho-ke leli phuzu libizwa nangokuthi iphoyinti lokusetha ithuluzi. Lapho uhlanganisa uhlelo, indawo yokumisa ithuluzi kufanele ikhethwe ngendlela efanele. Umgomo wokulungiselelwa kwephuzu lokusetha ithuluzi ukwenza lula ukucutshungulwa kwezinombolo nokwenza lula ukuhlela.

Kulula ukuvumelanisa nokuhlola ngesikhathi sokucubungula; iphutha lokucubungula elibangelwe lincane. Indawo yokusetha ithuluzi ingasethwa engxenyeni emshinini, ku-fixture noma ethuluzini lomshini. Ukuze kuthuthukiswe ukunemba komshini kwengxenye, iphoyinti lokusetha ithuluzi kufanele lisethwe ngangokunokwenzeka kusithenjwa somklamo wengxenye noma isisekelo senqubo. Ekusebenzeni kwangempela kwethuluzi lomshini, indawo yokuma yethuluzi yethuluzi ingabekwa endaweni yokuhlela ithuluzi ngokusebenza kokusetha ithuluzi okwenziwa ngesandla, okungukuthi, ukuqondana "kwephuzu lendawo yethuluzi" kanye "nephuzu lokusetha ithuluzi". Okubizwa ngokuthi "iphoyinti lendawo yethuluzi" kubhekisela endaweni yedatha yokuma yethuluzi, futhi indawo yethuluzi lethuluzi lokujika iyithiphu yethuluzi noma isikhungo se-arc yethiphu yethuluzi.

Isigayo sokugcina esiphansi esiphansi siyindawo yokuhlangana ye-eksisi yamathuluzi kanye naphansi kwethuluzi; i-ball-end mill iyisikhungo sebhola, futhi i-drill iphuzu. Ngokusebenzisa ukusebenza kokulungiselelwa kwamathuluzi okwenziwa ngesandla, ukunemba kwesilungiselelo samathuluzi kuphansi, futhi ukusebenza kahle kuphansi. Ezinye izimboni zisebenzisa izibuko zokusethwa kwamathuluzi okubona, amathuluzi okusetha amathuluzi, amathuluzi okusetha amathuluzi azenzakalelayo, njll. ukuze kuncishiswe isikhathi sokusetha ithuluzi nokuthuthukisa ukunemba kwesilungiselelo samathuluzi. Lapho ithuluzi lidinga ukushintshwa ngesikhathi sokucubungula, iphuzu lokushintsha ithuluzi kufanele licaciswe. Okubizwa ngokuthi "iphoyinti lokushintsha ithuluzi" kubhekisela endaweni yokuthunyelwe kwethuluzi lapho lizungezisa ukushintsha ithuluzi. Iphuzu lokushintsha ithuluzi kufanele libe ngaphandle kwendawo yokusebenza noma indawo, futhi i-workpiece nezinye izingxenye akufanele zithintwe ngesikhathi sokushintsha ithuluzi.

Ithiphu yalolu hlobo lwethuluzi lokujika lakhiwe imiphetho eqondile eyinhloko neyesibili yokusika, njengamathuluzi okujika angama-900 angaphakathi nangaphandle, amathuluzi okuguqula ubuso kwesokunxele nakwesokudla, amathuluzi okujika ama-grooving (akusike), kanye nemiphetho ehlukahlukene yokusika yangaphandle neyangaphakathi ama-tip chamfers amancane. Ithuluzi lokuvula imbobo. Indlela yokukhetha yamapharamitha wejiyomethri wethuluzi lokujika elicijile (ikakhulukazi i-engeli yejometri) ngokuyisisekelo iyafana naleyo yokujika okuvamile, kodwa izici zomshini we-CNC (njengomzila womshini, ukuphazamiseka kwemishini, njll.) kufanele zicatshangelwe ngokugcwele. , futhi ithiphu lamathuluzi ngokwalo kufanele libhekwe njengamandla.

Nquma Inani Lokusika

Ohlelweni lwe-NC, umdidiyeli wohlelo kufanele anqume inani elinqunyiwe lenqubo ngayinye futhi alibhale ohlelweni ngendlela yemiyalelo. Imingcele yokusika ihlanganisa isivinini sokuphotha, inani lokusika emuva kanye nesivinini sokuphakelayo. Ngezindlela ezahlukene zokucubungula, imingcele yokusika ehlukene idinga ukukhethwa. Umgomo wokukhetha yenani lokusika uwukuqinisekisa ukunemba komshini kanye nobulukhuni bezingxenye, ukunikeza ukudlala okugcwele ekusebenzeni kokusika kwethuluzi, ukuqinisekisa ukuqina kwethuluzi okunengqondo, nokunikeza ukudlala okugcwele ekusebenzeni kwethuluzi lomshini ukuze kwandiswe ukukhiqiza. futhi unciphise izindleko.