I-CNC Auto Parts Umkhiqizi Ochwepheshe

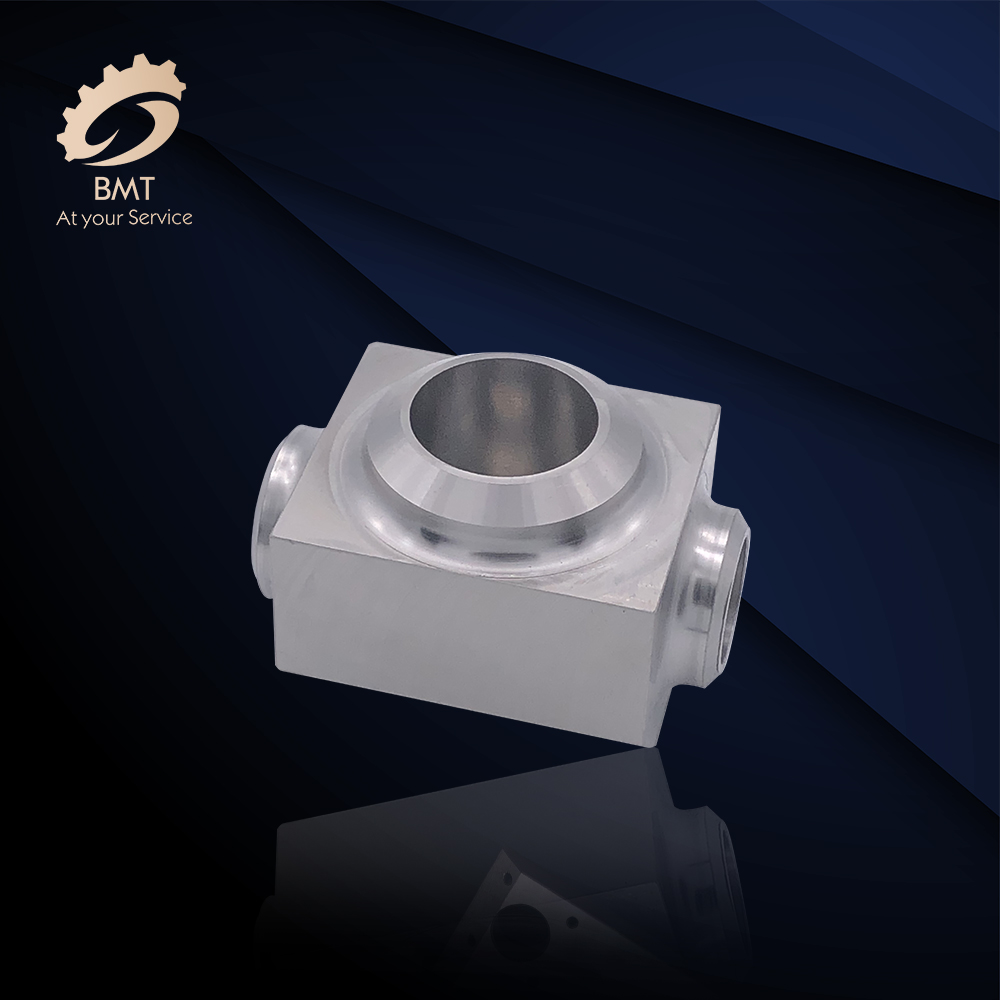

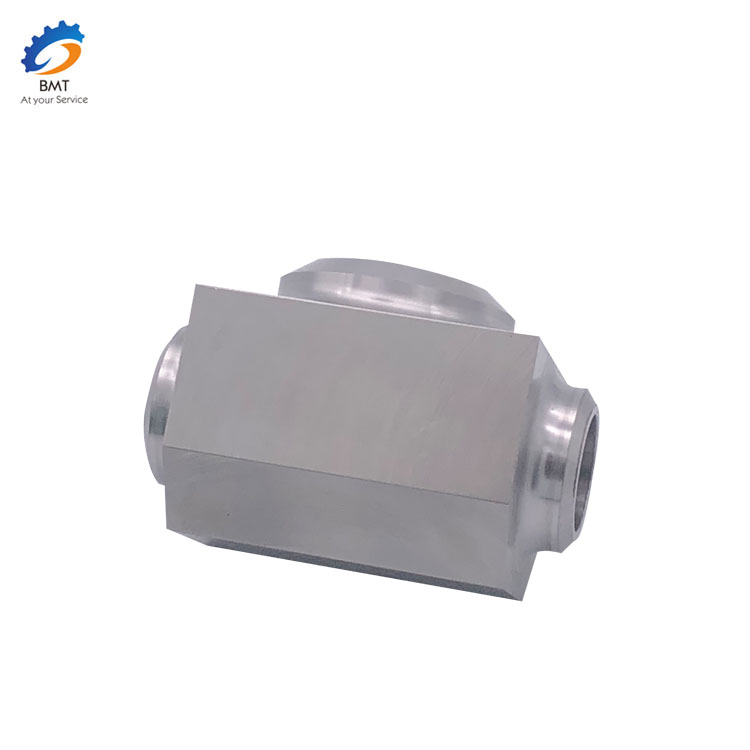

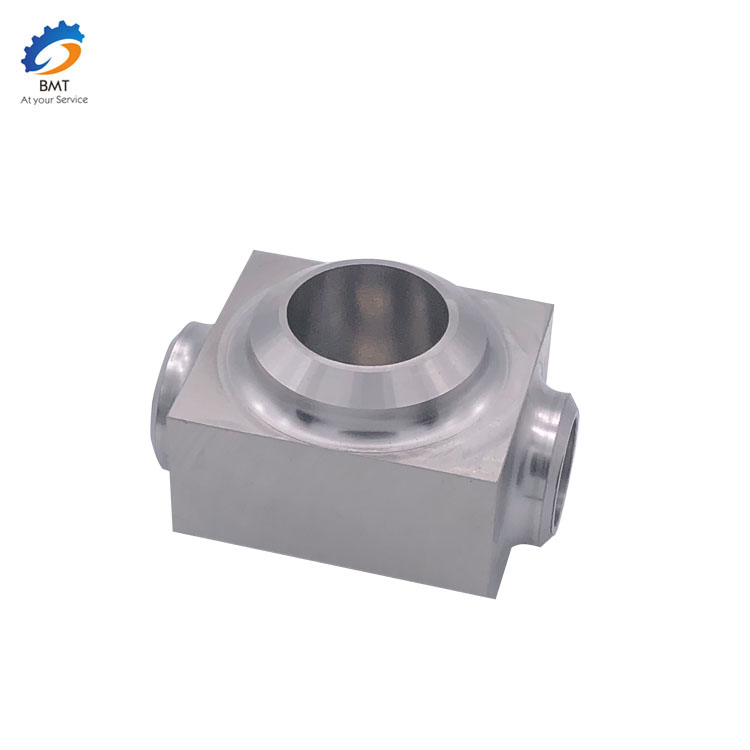

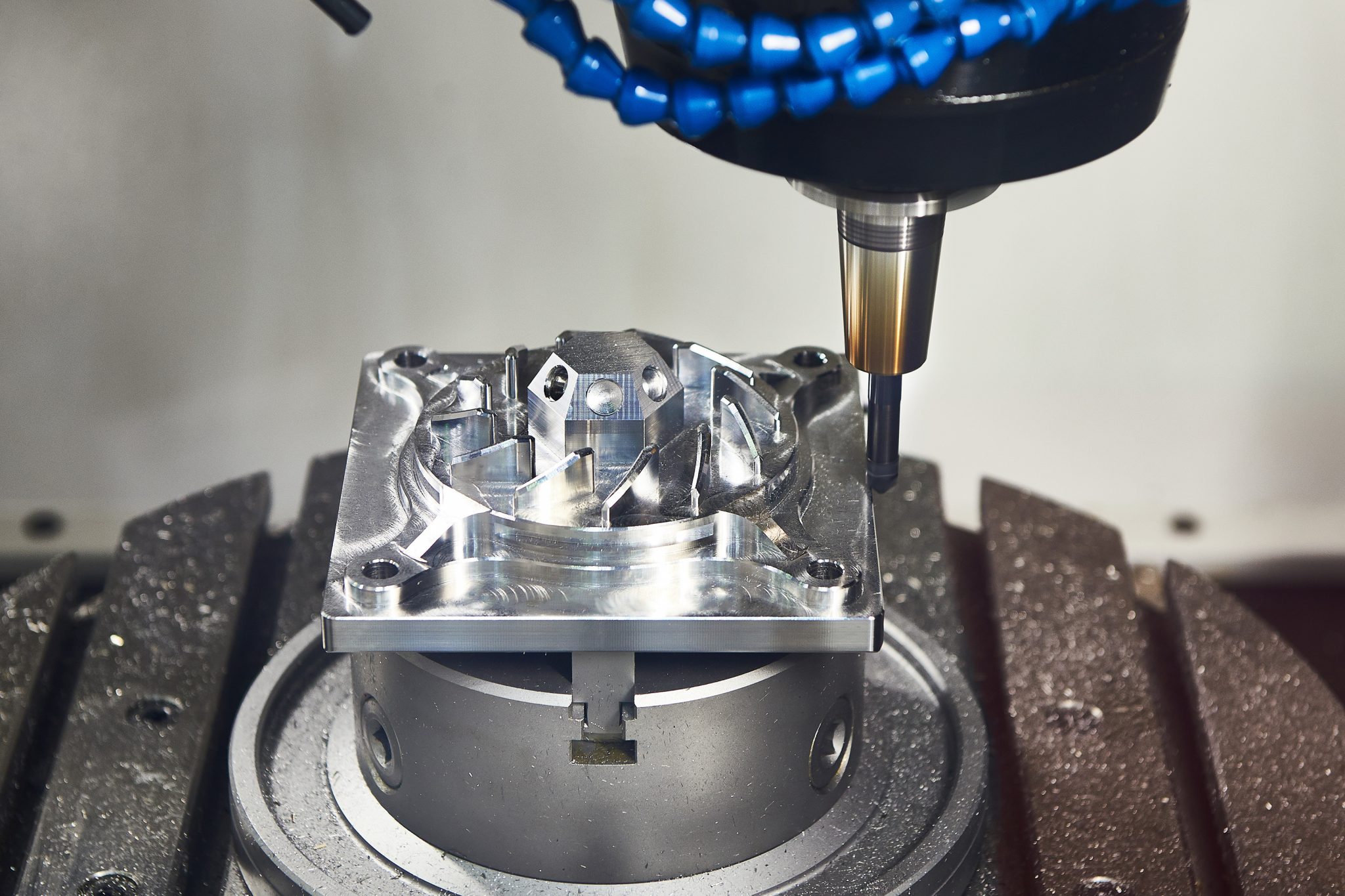

I-BMT igxile ekwenzeni ukunemba, ukucutshungulwa kwezingxenye ezingajwayelekile, ukucutshungulwa kwezingxenye eziningi ze-CNC, ukucutshungulwa kwezinombolo zemoto, i-batch titanium alloy ekucutshungulweni kwezingxenye eziqondile kakhulu, ukucutshungulwa kwezingxenye zeshaft, ukucutshungulwa kwezingxenye ze-semiconductor, njll., inolwazi olucebile, ifakwe ngesikhungo somshini we-CNC, izinsimbi ze-CNC, ukusika izintambo, umshini wokugaya, umshini wokugaya, oqoshiwe, ithuluzi lokulinganisa izixhumanisi ezintathu, ithuluzi lokulinganisa ubude kanye nezinye izinto zokukhiqiza nokunemba okuphezulu okuphezulu.

1. Hlaziya imidwebo yokucubungula futhi unqume inqubo yokucubungula

Ngokusho kwemidwebo yokucubungula ehlinzekwe yikhasimende, abasebenzi benqubo bangakwazi ukuhlaziya ukwakheka, ukunemba kobukhulu, ukugoqa okuphezulu, impahla yokusebenza, uhlobo olungenalutho kanye nesimo sokwelashwa kokushisa kwezingxenye, bese ukhetha ithuluzi lomshini, ithuluzi, ukucacisa ukugoqa indawo. idivayisi, indlela yokucubungula, ukulandelana kokucubungula kanye nosayizi womthamo wokusika. Enqubweni yokunquma inqubo yomshini, umsebenzi womyalo wethuluzi lomshini we-CNC kufanele ucatshangelwe ngokugcwele, unikeze ukudlala okugcwele ekusebenzeni kahle kwethuluzi lomshini, ukuze umzila wokucubungula ube onengqondo, izikhathi ezimbalwa zommese kanye nesikhathi esifushane sokucubungula.

2. Bala inani lokuxhumanisa lendlela yamathuluzi ngokunengqondo

Ngokusho kosayizi wejometri wengxenye yomshini kanye nesistimu yokuhlanganisa izinhlelo ezihleliwe, indlela yokunyakaza yesikhungo somzila wokusika ibalwa, futhi yonke idatha yendawo yokusika iyatholakala. Uhlelo olujwayelekile lwe-CNC lunomsebenzi wokuhumusha ngomugqa kanye nokufaka isiyingi, ukuze kube nezingxenye ezilula zomumo wepulani, njengezingxenye zomugqa kanye ne-arc contour machining, zidinga kuphela ukubala izakhi zejometri zephoyinti lokuqala nendawo yokugcina, i-arc eyindilinga yesiyingi ( noma irediyasi eyindilinga ye-arc), iphoyinti lokuphambana kwento emibili yejiyomethri noma amanani okuxhumanisa amaphoyinti e-tangent. Uma isistimu ye-nc ingenawo umsebenzi wesinxephezelo sethuluzi, inani lokuxhumanisa isikhungo sethuluzi kufanele libalwe. Ezingxenyeni ezinomumo oyinkimbinkimbi (njengezingxenye ezakhiwe ijika elingelona isiyingi nendawo), kuyadingeka ukusebenzisa ingxenye yomugqa oqondile (noma ingxenye ye-arc) ukuze ulinganisele ijika langempela noma indawo, futhi ubale inani lokuxhumanisa ama-node ngokuya ngokunemba komshini odingekayo.

3. Bhala uhlelo lwe-CNC lwezingxenye

Ngokwezingxenye zomzila wommese wokubala idatha yendlela yamathuluzi kanye nemingcele yenqubo inqunyiwe kanye nesinyathelo esiyisizayo, abasebenzi abahlelayo bangahambisana nokusetshenziswa kohlelo lokulawula lwe-NUMERICAL olubalulwe emiyalweni yokusebenza kanye nefomethi yohlelo, isigaba ngo-. isigaba sokubhala izingxenye zohlelo lokucubungula. Kufanele kuqashelwe: okokuqala, ukumiswa kokubhala kohlelo kufanele kube lula ukukuveza nokuxhumana; Okwesibili, ekusetshenzisweni kokusebenza kwethuluzi lomshini we-CNC kanye nemiyalelo ngesisekelo sokujwayelana okugcwele, imiyalelo yokusetshenziswa kwamakhono, amakhono okuhlela.