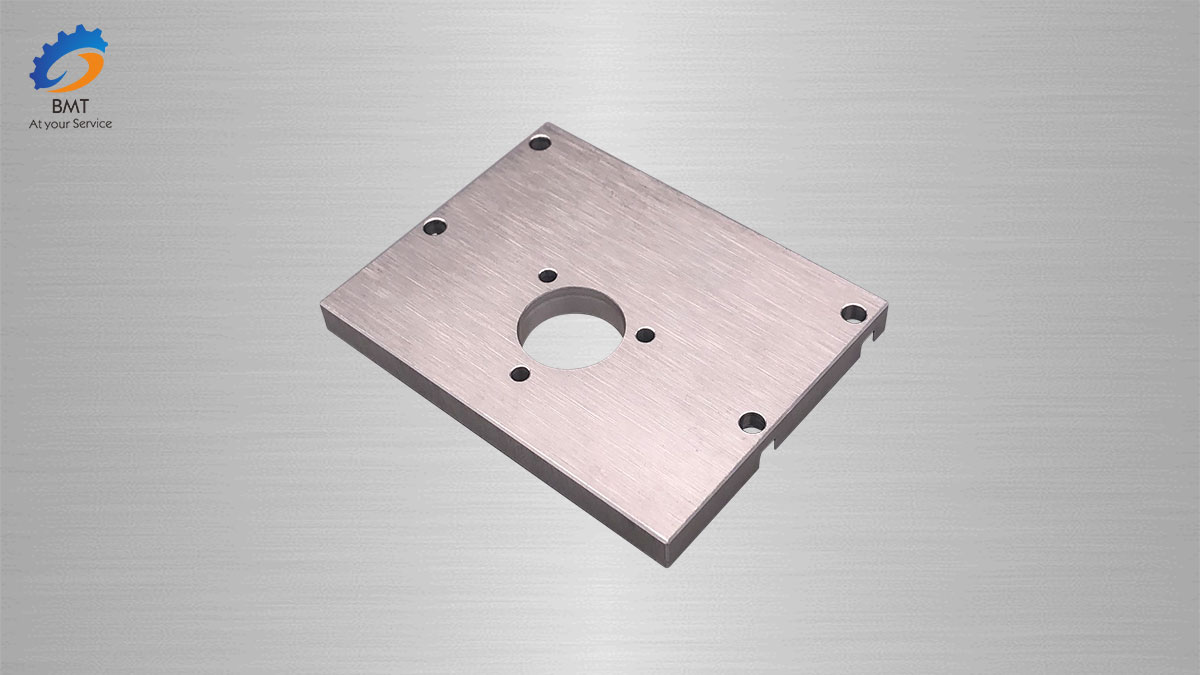

I-CNC Machining Processing Analysis

Ukuhlaziywa kwenqubo

Izinkinga zobuchwepheshe ze-CNC machining yezingxenye ezicutshunguliwe zibandakanya izici eziningi. Okulandelayo kuhlanganisa ukuba nokwenzeka kanye nokuba lula kwezinhlelo ukubeka phambili okunye okuqukethwe okubalulekile okufanele kuhlaziywe futhi kubuyekezwe.

Ubukhulu bokugoqa kufanele buhambisane nezici zemishini ye-CNC

Kuhlelo lwe-CNC, usayizi nendawo yawo wonke amaphuzu, imigqa, nezindawo zisekelwe kumsuka wohlelo. Ngakho-ke, kungcono ukunikeza usayizi wokuxhumanisa ngokuqondile engxenyeni yomdwebo, noma uzame ukucaphuna usayizi nge-datum efanayo.

Izimo zokugoqa izakhi zejometri kufanele ziphelele futhi zinembile

Ohlelweni, umhleli kufanele abambe ngokugcwele amapharamitha wesici sejiyomethri akha i-contour yengxenye kanye nobudlelwano phakathi kwezinto zejiyomethri. Ngenxa yokuthi zonke izakhi zejiyomethri ze-contour yengxenye kufanele zichazwe ngesikhathi sokuhlela okuzenzakalelayo, izixhumanisi ze-node ngayinye kufanele zibalwe ngesikhathi sokuhlela okwenziwa ngesandla. Kungakhathaliseki ukuthi yiliphi iphuzu elingacacile noma elingaqinisekile, ukuhlela akukwazi ukwenziwa. Kodwa-ke, ngenxa yokucatshangelwa okwanele noma ukunganakwa abaklami bengxenye enqubweni yokuklama, kuvame ukuba nemingcele engaphelele noma engacacile, njenge-arc kanye nomugqa oqondile, i-arc ne-arc ukuthi i-tangent noma i-intersecting noma ihlukanisiwe. Ngakho-ke, lapho ubuyekeza futhi uhlaziya imidwebo, kufanele uqaphele futhi uxhumane nomklami ngesikhathi uma uthola izinkinga.

Idatha yendawo egoqiwe enokwethenjelwa

Ekwenziweni kwemishini ye-CNC, izinqubo zemishini zivame ukugxila, futhi kubaluleke kakhulu ukuzithola ngesisekelo esifanayo. Ngakho-ke, ngokuvamile kuyadingeka ukusetha ama-datum athile asizayo, noma wengeze abaphathi bezinqubo endaweni engenalutho.

Songa uhlobo lwejiyomethri efanayo noma usayizi

Kungcono ukwamukela uhlobo olufanayo lwejometri noma usayizi wesimo kanye nomgodi wangaphakathi wengxenye, ukuze inani lezinguquko zethuluzi lincishiswe, futhi kungenzeka futhi ukusebenzisa uhlelo lokulawula noma uhlelo olukhethekile lokunciphisa ubude. yohlelo. Umumo wezingxenye ulingana ngangokunokwenzeka, okulungele ukuhlela ngokusebenza kwesibuko sethuluzi lomshini we-CNC ukuze wonge isikhathi sokuhlela.