CNC Machining Amaphutha 2

Amaphutha abangelwa ukuguqulwa okushisayo kwesistimu yenqubo Ukuguqulwa kwe-thermal kwesistimu yenqubo kunomthelela omkhulu emaphutheni omshini, ikakhulukazi ekusetshenzisweni okunembayo kanye nemishini emikhulu, amaphutha omshini abangelwa ukuguqulwa kokushisa ngezinye izikhathi angabangela u-50% wephutha eliphelele le-workpiece.

Lungisa iphutha kunqubo ngayinye yokwenza, njalo ohlelweni lwenqubo ukuze wenze uhlobo olulodwa lomsebenzi wokulungisa. Ngenxa yokuthi ukulungiswa akukwazi ukunemba ngokuphelele, kwenzeka iphutha lokulungisa. Kuhlelo lwenqubo, ukunemba kwesikhundla se-workpiece kanye nethuluzi ethuluzini lomshini kuqinisekiswa ngokulungisa ithuluzi lomshini, ithuluzi, i-fixture noma i-workpiece. Lapho ukunemba kwasekuqaleni kwethuluzi lomshini, ithuluzi lokusika, i-fixture kanye ne-workpiece engenalutho konke kuhlangabezana nezidingo zobuchwepheshe ngaphandle kokucabangela izici eziguqukayo, iphutha lokulungisa lidlala indima ebalulekile ephutheni lomshini.

Izingxenye zephutha lokulinganisa enqubweni noma ngemva kwenqubo yokulinganisa, ngenxa yendlela yokulinganisa, ukunemba kokulinganisa kanye nomsebenzi wokusebenza kanye nezici ezizimele nezinjongo zithinta ngokuqondile ukunemba kokulinganisa. I-9, ukucindezeleka kwangaphakathi ngaphandle kwamandla angaphandle futhi kukhona ezingxenyeni zokucindezeleka kwangaphakathi, okubizwa ngokuthi ukucindezeleka kwangaphakathi. Uma ukucindezeleka kwangaphakathi sekwenziwe ku-workpiece, kuzokwenza insimbi yokusebenza ibe sesimweni esingazinzile samandla aphezulu. Izoshintsha ngokuzenzekelayo ibe yisimo esizinzile samandla aphansi anamandla, ahambisana nokuguqulwa, ukuze umsebenzi womsebenzi ulahlekelwe ukunemba kwawo kokucubungula kwangempela.

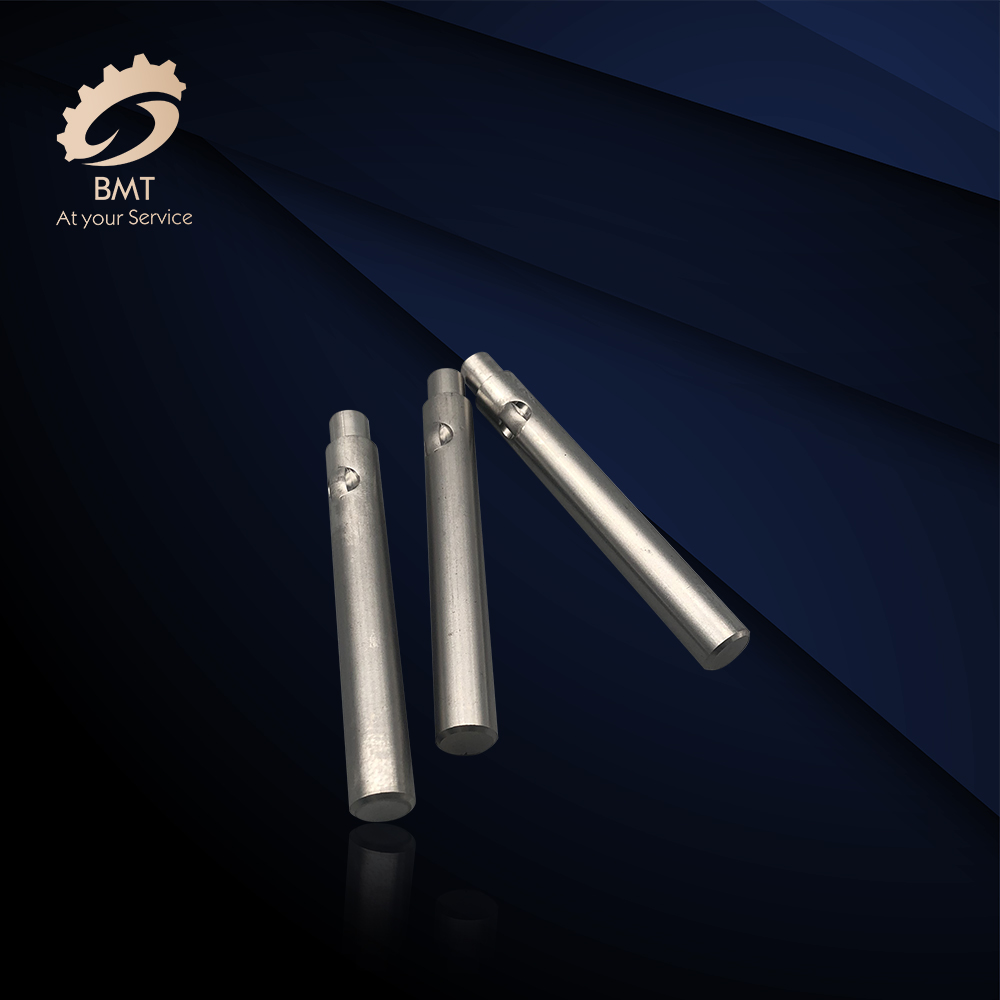

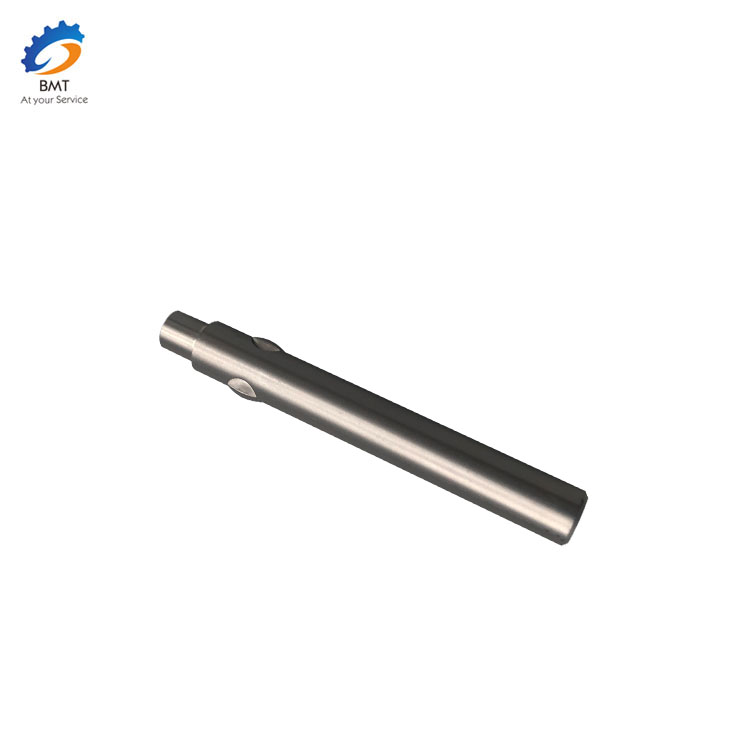

Amathuluzi enqubo yokucubungula imishini ibaluleke kakhulu, iqondile futhi ikhwalithi yokucubungula kanye nokunemba kokucubungula kuhlobene eduze, ekuthuthukisweni okusheshayo kokukhiqiza ukucubungula namuhla, izinto ezihlukahlukene ezintsha, ubuchwepheshe obusha buvela ngokungapheli, ithuluzi lempahla kanye ubuchwepheshe bubuye bushintshe njalo ekuvuselelweni. Lapho ubhekene nezidingo ezikhulayo zokucubungula, njengomuntu owenza imishini ukuqonda izinhlobo zamathuluzi nezindinganiso zokukhetha amathuluzi, namuhla i-BMT izofika izokhuluma nawe: yiziphi izinhlobo zamathuluzi ekwenzeni imishini? Indlela yokukhetha ithuluzi?

Yiziphi izinhlobo zamathuluzi okusika emishinini?

1. Ngokusho kwesigaba sezinto zethuluzi

Insimbi enesivinini esikhulu: amandla okugoba aphezulu kanye nokuqina komthelela, ukusebenza kahle.

I-Hard alloy: indlela yokubeka umhwamuko wamakhemikhali embozwe nge-titanium carbide, i-titanium nitride, ungqimba oluqinile lwe-alumina noma ungqimba oluqinile oluhlanganisiwe, ukuze ithuluzi liguge libe liphansi, impilo ende yesevisi.

2. Ngokusho kokunyakaza kokusika kokuhlukaniswa kwethuluzi

Amathuluzi ajwayelekile: amathuluzi asetshenziswa kakhulu, iplanethi, i-milling cutter, i-boring cutter, i-drill, i-reaming drill, i-reamer nesaha.

Amathuluzi okwakha: ithuluzi lokwakha elivame ukusetshenziswa, iplanethi yokwakha, i-milling cutter, i-broach, i-taper reamer kanye nazo zonke izinhlobo zamathuluzi okucubungula intambo.

Amathuluzi okuthuthukisa: i-hob evame ukusetshenziswa, i-gear shaper, i-gear shaver, i-bevel gear planer kanye ne-bevel gear milling cutter disc, njll.

3. Ngokusho komsebenzi wethuluzi ukuhlukaniswa kwengxenye

Okubalulekile: unqenqema lokusika lwenziwa emzimbeni wommese.

Uhlobo lokushisela: ukuqinisa i-blade emzimbeni wommese wensimbi

Ukugoqa ngomshini: i-blade iboshelwe emzimbeni wommese, noma inhloko yommese iboshwe emzimbeni wommese.