CNC Machining Operational Safety

Impucuzeko Production

Amathuluzi omshini we-CNC ayimishini yokucubungula eseqophelweni eliphezulu enezinga eliphezulu lokuzenzakalela kanye nesakhiwo esiyinkimbinkimbi. Ukuze unikeze ukudlala okuphelele ekuphakameni kwamathuluzi omshini, kuthuthukiswe ukusebenza kahle kokukhiqiza, ukuphatha, ukusebenzisa, nokulungisa amathuluzi omshini we-CNC, ikhwalithi yochwepheshe nokukhiqiza okuphucuzekile kubaluleke kakhulu. . Ngaphezu kokujwayela ukusebenza kwamathuluzi emishini ye-CNC, opharetha kufanele futhi bakhe imikhuba emihle yokusebenza nezitayela eziqinile zokusebenza ekukhiqizeni okuphucuzekile, futhi babe nezimfanelo ezinhle zobungcweti, umuzwa wokuba nesibopho nomoya wokubambisana. Amaphuzu alandelayo kufanele enziwe ngesikhathi sokusebenza:

(1) Ukuthobela ngokuqinile imithethonqubo yokusebenza ephephile yamathuluzi omshini we-CNC. Ungawusebenzisi umshini ngaphandle kokuqeqeshwa kochwepheshe.

(2) Landela ngokuqinile uhlelo lokuya emsebenzini nokushintshashintsha.

(3) Sebenzisa futhi uphathe umshini kahle, futhi ube nomuzwa onamandla wokuzibophezela komsebenzi.

(4) Gcina imvelo ezungeze ithuluzi lomshini we-CNC ihlanzekile futhi icocekile.

(5) Abaqhubi kufanele bagqoke izingubo zokusebenza nezicathulo zokusebenza, futhi akukho zimpahla eziyingozi okufanele zigqokwe noma zigqokwe.

Izinqubo Zokusebenza Zokuphepha

Ukuze usebenzise ithuluzi lomshini we-CNC ngendlela efanele nangendlela efanele, nciphisa izehlakalo zokuhluleka kwalo, indlela yokusebenza. Ithuluzi lomshini lingasetshenziswa kuphela ngemvume yomphathi wethuluzi lomshini.

(1) Izinyathelo Zokuqaphela Ngaphambi Kokuqala

1) Umsebenzisi kufanele ajwayele ukusebenza nezindlela zokusebenza zethuluzi lomshini we-CNC. Ithuluzi lomshini lingasetshenziswa kuphela ngemvume yomphathi wethuluzi lomshini.

2) Ngaphambi kokufaka amandla ethuluzini lomshini, hlola ukuthi i-voltage, ingcindezi yomoya, nomfutho kawoyela kuyahlangabezana yini nezidingo zokusebenza.

3) Hlola ukuthi ingxenye enyakazayo yethuluzi lomshini isesimweni esijwayelekile sokusebenza.

4) Hlola ukuthi asikho yini isimo sokulalela noma sokukhawulela ebhentshini lokusebenza.

5) Hlola ukuthi izingxenye zikagesi ziqinile yini nokuthi izintambo zivaliwe yini.

6) Hlola ukuthi intambo yaphansi yethuluzi lomshini ixhunywe ngokuthembekile yini ocingweni lwaphansi lweshabhu (ibaluleke kakhulu ekuqaliseni kokuqala).

7) Vula inkinobho enkulu yamandla kuphela ngemva kokuba amalungiselelo ngaphambi kokuqala umshini sekuqediwe.

(2) Izinyathelo zokuqapha ngesikhathi se-Boot Process

1) Sebenza ngokuqinile ngokuhambisana nokulandelana kokuqalisa kubhukwana lamathuluzi omshini.

2) Ngaphansi kwezimo ezijwayelekile, kufanele uqale ubuyele endaweni yereferensi yomshini phakathi nenqubo yokuqalisa ukuze usungule ithuluzi lomshini njengesistimu evamile.

3) Ngemuva kokuqala umshini, vumela umshini uphele imizuzu engaphezu kwe-15 ukwenza umshini ufinyelele esimweni esilinganiselwe.

I-4) Ngemuva kokuvala, kufanele ulinde imizuzu engaphezu kwe-5 ngaphambi kokuqala futhi, futhi akukho ukuqalisa noma ukuvala ukuvala okuvamile okuvunyelwe ngaphandle kwezimo ezikhethekile.

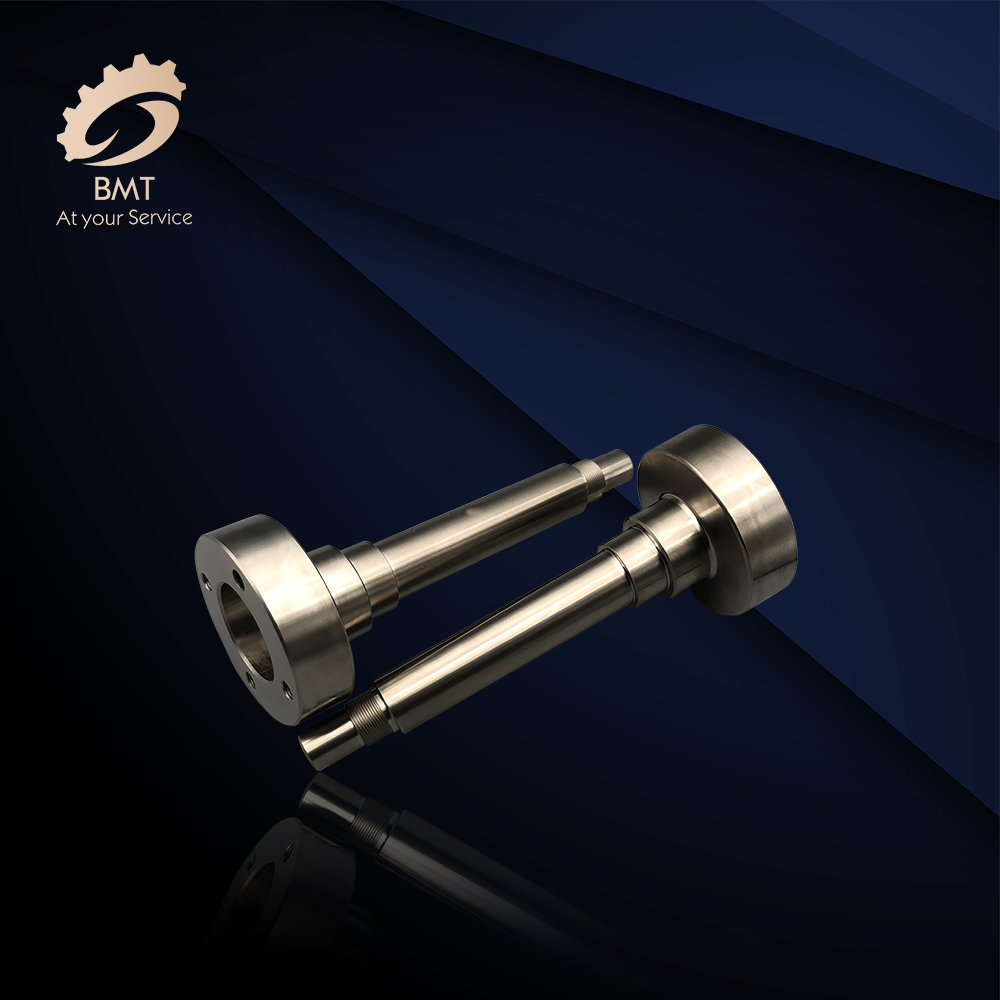

Ithiphu yalolu hlobo lwethuluzi lokujika lakhiwe imiphetho eqondile eyinhloko neyesibili yokusika, njengamathuluzi okujika angama-900 angaphakathi nangaphandle, amathuluzi okuguqula ubuso kwesokunxele nakwesokudla, amathuluzi okujika ama-grooving (akusike), kanye nemiphetho ehlukahlukene yokusika yangaphandle neyangaphakathi ama-tip chamfers amancane. Ithuluzi lokuvula imbobo. Indlela yokukhetha yamapharamitha wejiyomethri wethuluzi lokujika elicijile (ikakhulukazi i-engeli yejometri) ngokuyisisekelo iyafana naleyo yokujika okuvamile, kodwa izici zomshini we-CNC (njengomzila womshini, ukuphazamiseka kwemishini, njll.) kufanele zicatshangelwe ngokugcwele. , futhi ithiphu lamathuluzi ngokwalo kufanele libhekwe njengamandla.