I-Titanium Alloy Welding

Kuyingxube yesigaba esisodwa esakhiwe ngesixazululo esiqinile sesigaba esingu-β. Ngaphandle kokwelashwa kokushisa, inamandla aphezulu. Ngemva kokucisha nokuguga, i-alloy ithuthukisiwe.Isinyathelo esisodwa sokuqinisa, amandla okushisa ekamelweni angafinyelela ku-1372 ~ 1666 MPa; Kodwa ukuzinza okushisayo kubi, akufanele kusetshenziswe ekushiseni okuphezulu.

I-alloy ye-biphasic, inezici ezinhle eziphelele, ukuzinza okuhle kwesakhiwo, ukuqina okuhle, ipulasitiki kanye nezindawo zokushisa eziphakeme zokushisa, kungaba ngcono ekucubunguleni ingcindezi eshisayo, ingacinywa, ukuguga ukuqinisa i-alloy. Amandla ngemva kokwelashwa okushisa acishe abe ngu-50% ~ 100% ngaphezu kwalokho ngemva kokuhushulwa; Amandla okushisa aphezulu, angasebenza ekushiseni kuka-400℃ ~ 500℃ isikhathi eside, ukuzinza kwawo okushisayo kungaphansi kwe-alpha titanium alloy.

Phakathi kwama-alloys amathathu e-titanium, okuvame ukusetshenziswa kakhulu yi-α titanium alloy kanye ne-α+β titanium alloy; Ukusebenza kokusika kwe-α titanium alloy kuhamba phambili, kulandelwa i-α+β titanium alloy, kanye ne-β titanium alloy iyona embi kakhulu. Ikhodi ye-α titanium alloy ye-TA, β titanium alloy code ye-TB, α+β titanium alloy code ye-TC.

Ingxubevange ye-Titanium ingahlukaniswa ibe ingxubevange yokumelana nokushisa, ingxubevange yamandla aphezulu, ingxube ye-corrosion resistant (titanium - molybdenum, titanium - palladium alloy, njll.), ukushisa okuphansi kwe-alloy kanye ne-alloy ekhethekile yokusebenza (i-titanium - i-iron hydrogen storage material kanye ne-titanium - inkumbulo ye-nickel ingxubevange). Ukwakheka kanye nezakhiwo zama-alloys ajwayelekile kuboniswa etafuleni.

Ukuqanjwa kwesigaba esihlukile kanye ne-microstructure yama-alloys e-titanium aphethwe ukushisa kungatholwa ngokulungisa inqubo yokwelapha ukushisa. Ngokuvamile kunenkolelo yokuthi izakhiwo ezinhle ezilinganayo zine-plasticity engcono, ukuzinza okushisayo namandla okukhathala. Isakhiwo se-spiculate sinokuqina okuphezulu, amandla okukhasa kanye nokuqina kokuphuka. Izicubu ezixubile ezilinganayo kanye nenaliti zinezakhiwo ezibanzi ezingcono. I-Titanium iwuhlobo olusha lwensimbi, ukusebenza kwe-titanium kuhlobene nokuqukethwe kwekhabhoni, i-nitrogen, i-hydrogen, i-oksijini nokunye ukungcola, okuqukethwe kokungcola kwe-titanium iodide okumsulwa akukhona kuka-0.1%, kepha amandla ayo aphansi, ipulasitiki ephezulu .

Izakhiwo ze-99.5% ze-titanium emsulwa yezimboni zimi kanje: ukuminyana ρ=4.5g/cubic cm, indawo encibilikayo 1725℃, conductivity eshisayo λ=15.24W/(mK), amandla aqinile σb=539MPa, ubude δ=25%, isigaba ukuncipha ψ=25%, i-elastic modulus E=1.078×105MPa, ubulukhuni HB195. Ubuningi be-titanium alloy ngokuvamile buba ngu-4.51g/cubic centimeter, kuphela u-60% wensimbi, amandla e-titanium ehlanzekile asondelene namandla ensimbi evamile, amanye amandla aphezulu e-titanium alloy adlula amandla ensimbi eminingi ye-alloy structural. Ngakho-ke, amandla athile (amandla/ukuminyana) we-titanium alloy makhulu kakhulu kunezinye izinto zokwakha zensimbi, njengoba kuboniswe kuThebula 7-1. Ingakwazi ukukhiqiza izingxenye nezingxenye ezinamandla amakhulu eyunithi, ukuqina okuhle nesisindo esincane. Njengamanje, ama-alloys e-titanium asetshenziswa ezingxenyeni zenjini, amathambo, isikhumba, izinsimbi namagiya okufika.

Thumela umlayezo wakho kithi:

-

Izingxenye ze-Aluminium CNC Machining

-

I-Aluminium Sheet Metal Fabrication

-

I-Axis High Precision CNC Machining Izingxenye

-

Izingxenye Zomshini ze-CNC zase-Italy

-

CNC Machining Aluminium Izingxenye

-

Auto Parts Machining

-

I-Titanium Alloy Forgings

-

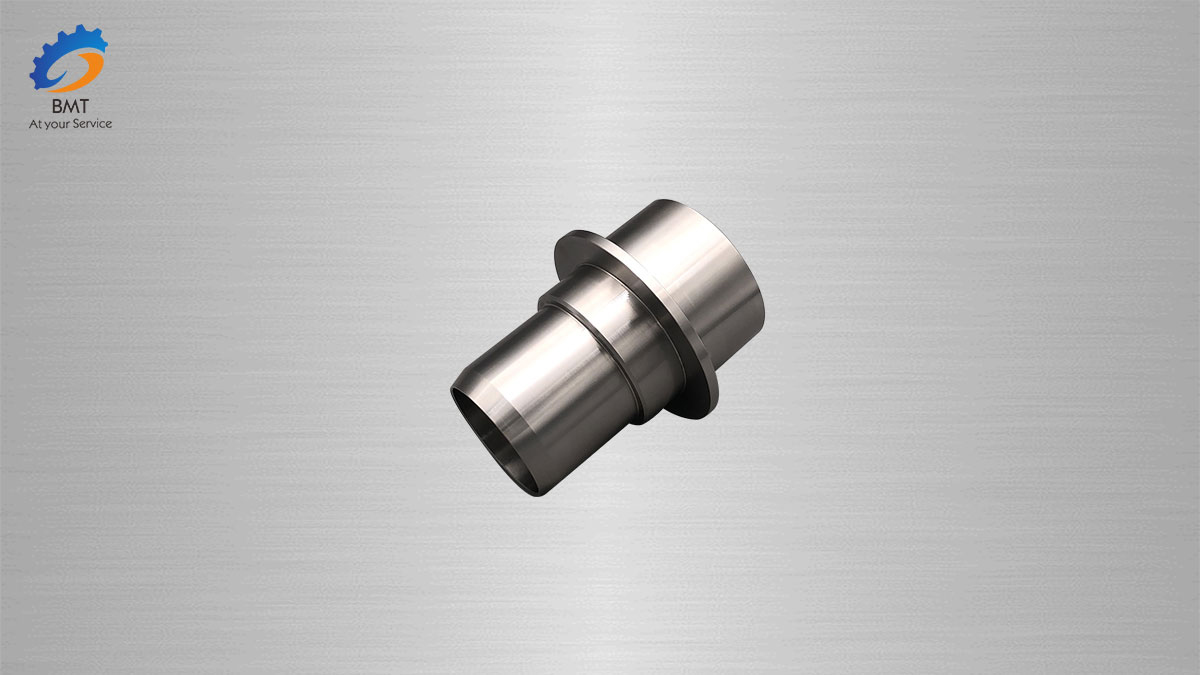

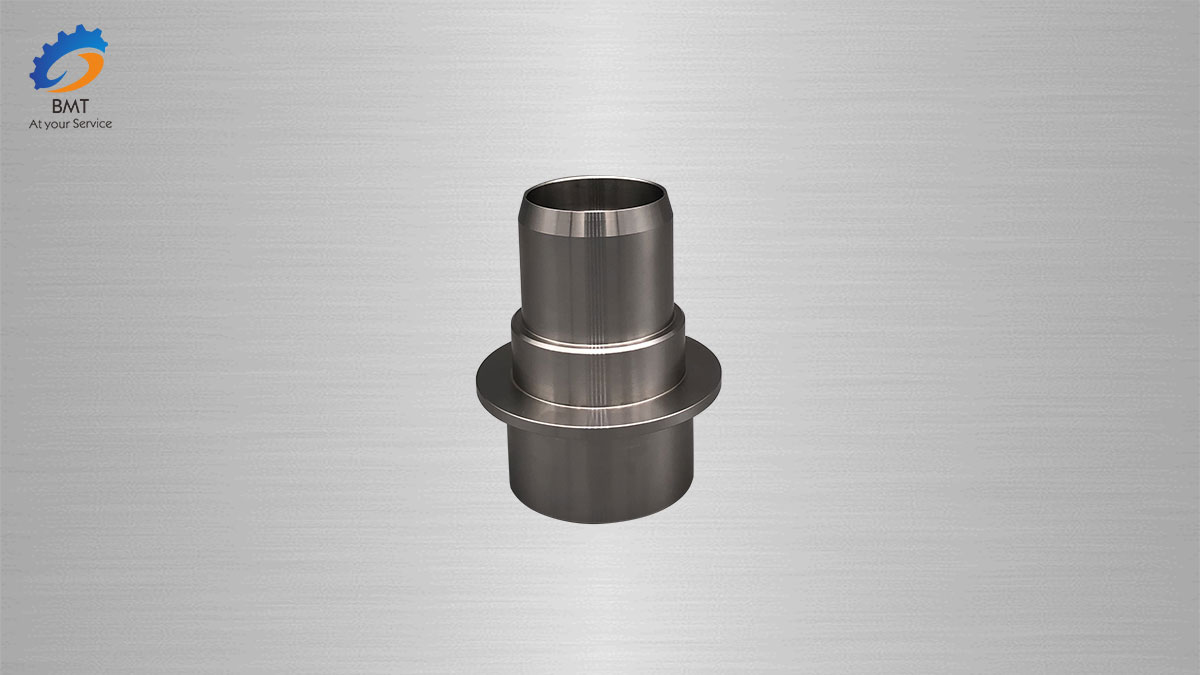

I-Titanium ne-Titanium Alloy Fittings

-

I-Titanium ne-Titanium Alloy Forgings

-

Izintambo ze-Titanium ne-Titanium Alloy

-

Amabha we-Titanium

-

Amapayipi/Amashubhu angenamthungo e-Titanium

-

I-Titanium Welded Pipes/Amashubhu